KENTURN KC1508H Spindle Repair

Professional KENTURN spindle repair

KC1508H 8000rpm

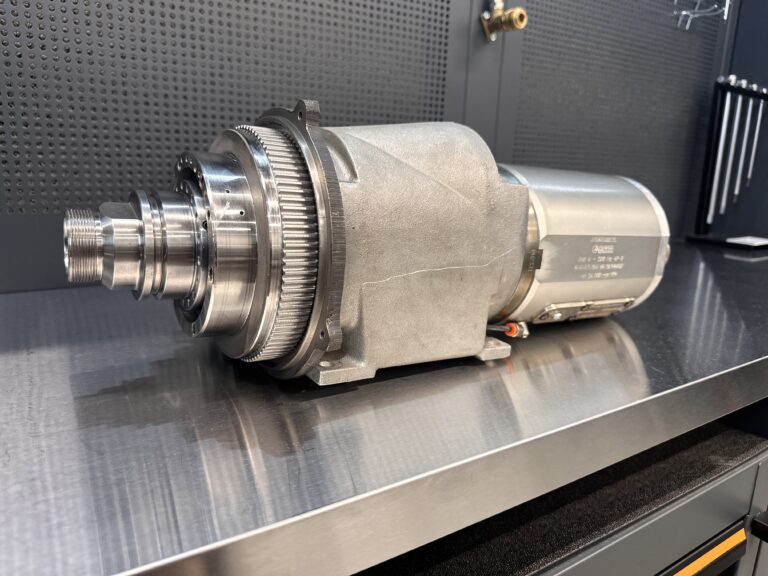

KENTURN KC1508H spindle repair is a critical process aimed at restoring its full operational performance. As part of our complete service, we handle disassembly, repair, and reinstallation of the spindle into the client’s machine. Each stage is carried out to the highest precision standards, ensuring long-lasting durability and reliability of the spindle.

KENTURN KC1508H

spindle repair steps

We begin by carefully removing the spindle from the machine to protect other components and avoid further damage.

Bearings have a critical impact on machining precision and smooth operation. We replace worn bearings with high-speed FAG types, known for durability and load resistance.

To ensure maximum stability, we perform dynamic balancing to 0.4G class, reducing vibration and extending component life.

Taper wear can cause tool clamping issues and reduced machining accuracy. We restore the SK50 taper to factory specs.

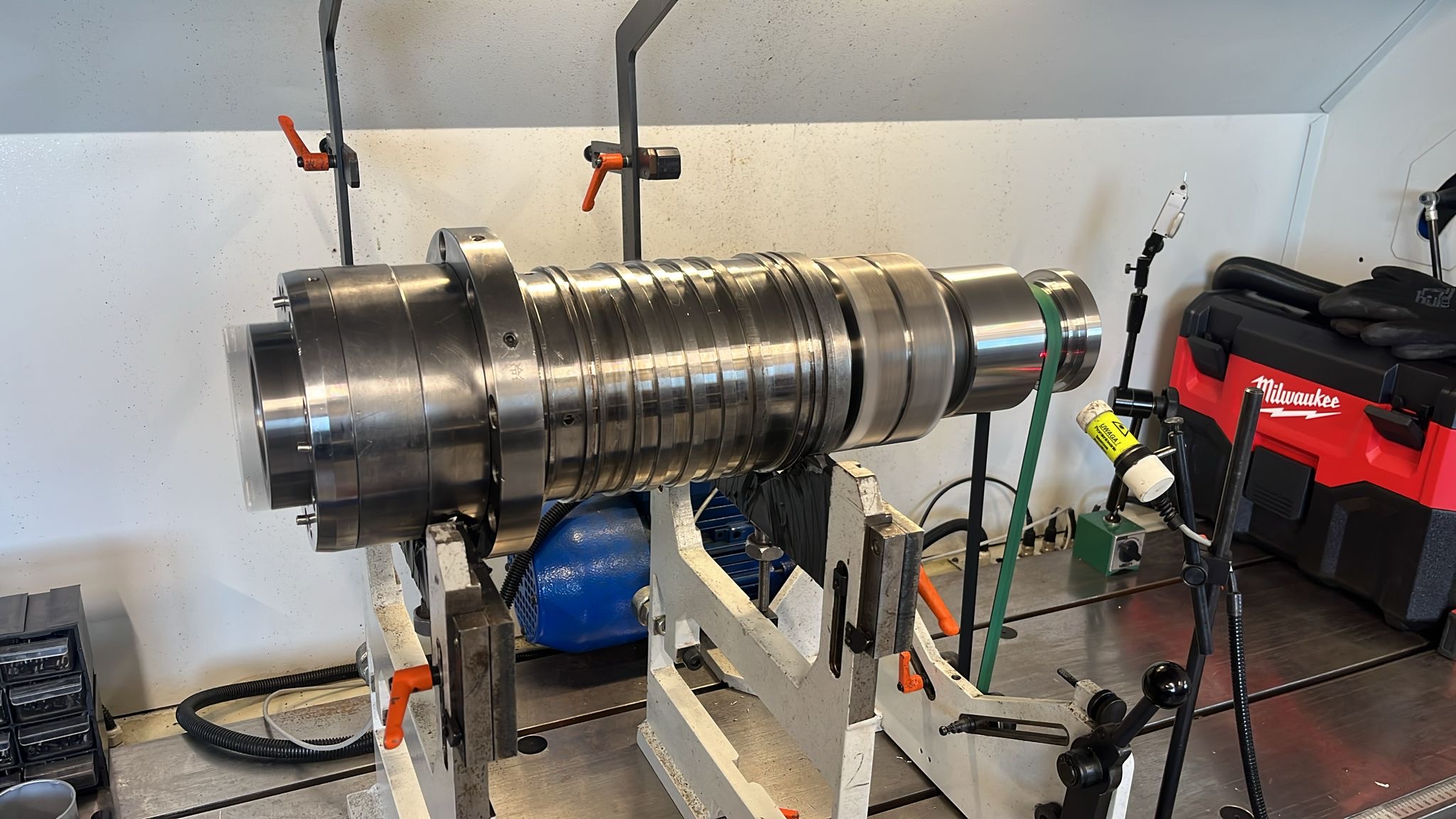

On our test stand, we conduct detailed break-in both before and after balancing. We monitor bearing temperatures to ensure optimal component alignment.

Before completing the repair, we test drawbar clamping performance — measuring runout and play to confirm stability and precision.

Once complete, the repaired spindle is returned and reinstalled in the machine. We ensure fast turnaround and minimal downtime.

Quality guarantee

6 months of peace of mind

Every KENTURN KC1508H spindle repair comes with a full 6-month service warranty.

We deliver top-quality service and peace of mind that your spindle will run reliably.

Need professional KENTURN spindle repair? Contact us and get your spindle back to full performance — fast!