Why are regular spindle inspections so important?

Regular tool clamping force measurement

the key to spindle longevity

Many CNC machine operators and machine park owners underestimate the importance of regular condition monitoring of spindles and electrospindles. One of the most critical parameters that should be monitored regularly is the tool clamping force — especially in HSK or SK tapers.

Why you should measure clamping force

at least once a year

Regular clamping force measurements allow you to:

- Detect early signs of tool retention mechanism wear,

- Diagnose cracked disc springs,

- Identify HSK gripper system failures in advance,

- Plan service and schedule machine downtime accordingly,

- Avoid major failures and costly spindle repairs.

By testing the clamping force of your spindle’s toolholder, we can quickly detect early signs of failure in the tool clamping system — whether it’s a spindle or electrospindle. With this knowledge, you can plan for scheduled service and contact a trusted provider like BMS SPINDLE SERVICE CNC to repair the clamping mechanism, most often due to failing springs or HSK gripper issues.

Early diagnosis and repair prevent serious damage such as taper deformation, which reduces precision and increases repair costs. In the worst-case scenario, it may lead to vibrations and bearing failure — resulting in the most expensive repairs and extended downtime.

What happens if you ignore

early warning signs

Failure to react to reduced clamping force may lead to:

- Taper deformation and loss of machining accuracy,

- Spindle looseness and instability,

- Vibration and bearing damage,

- Full spindle or electrospindle rebuild,

- Production delays and financial loss due to machine downtime.

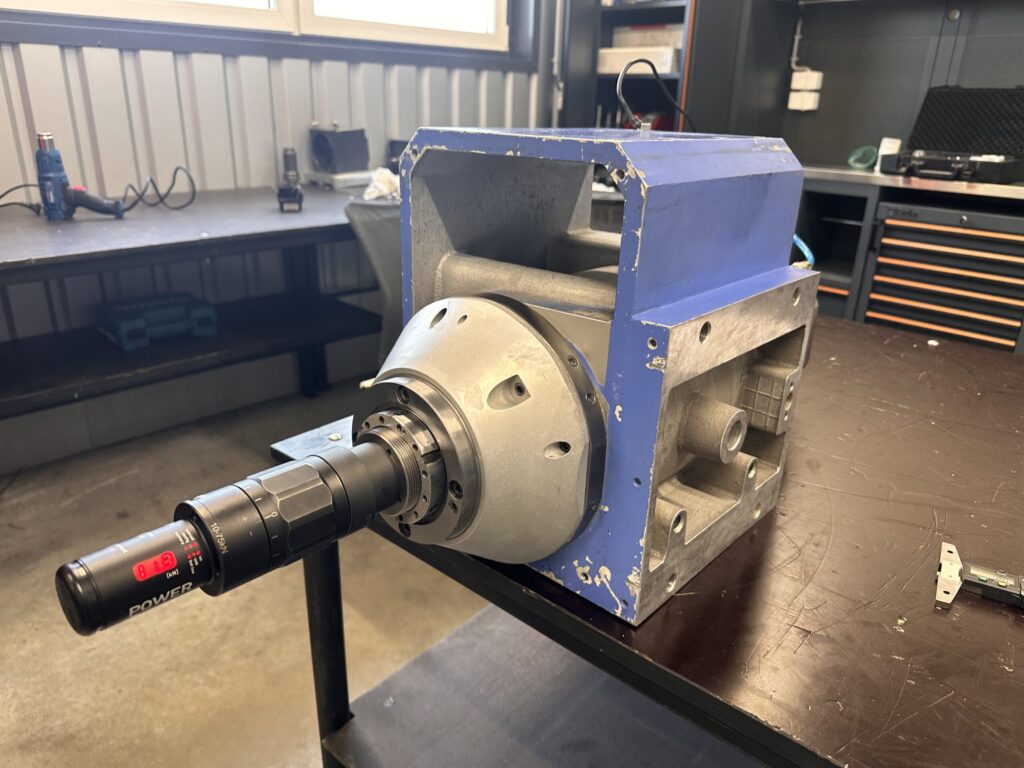

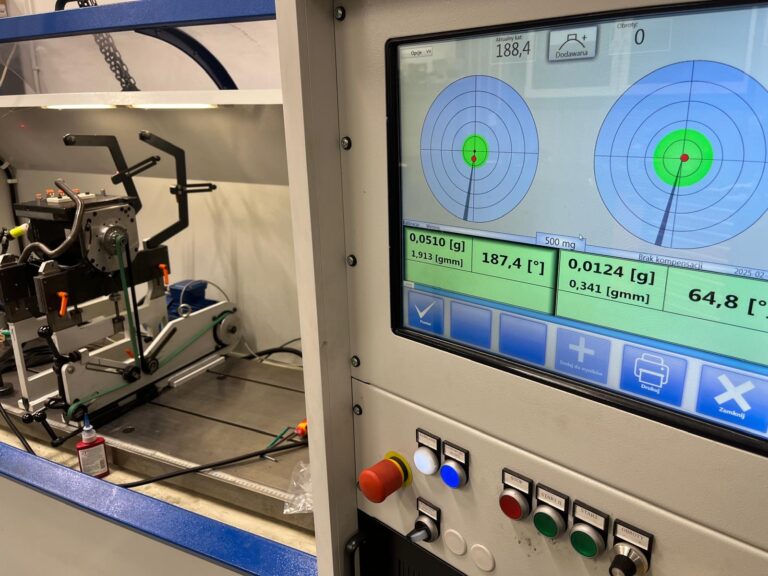

Examples of clamping force measurements

Performed by our team

Each of these tests allowed our clients to avoid major breakdowns and plan the necessary service actions in advance.

Don’t wait

take care of your spindle today

Don’t ignore the early signs of mechanical wear. Schedule a periodic technical inspection, repair essential spindle components, and lubricate the clamping system.

Got questions? Contact us – BMS SPINDLE SERVICE CNC. We’ll help you maintain the full performance of your machines!