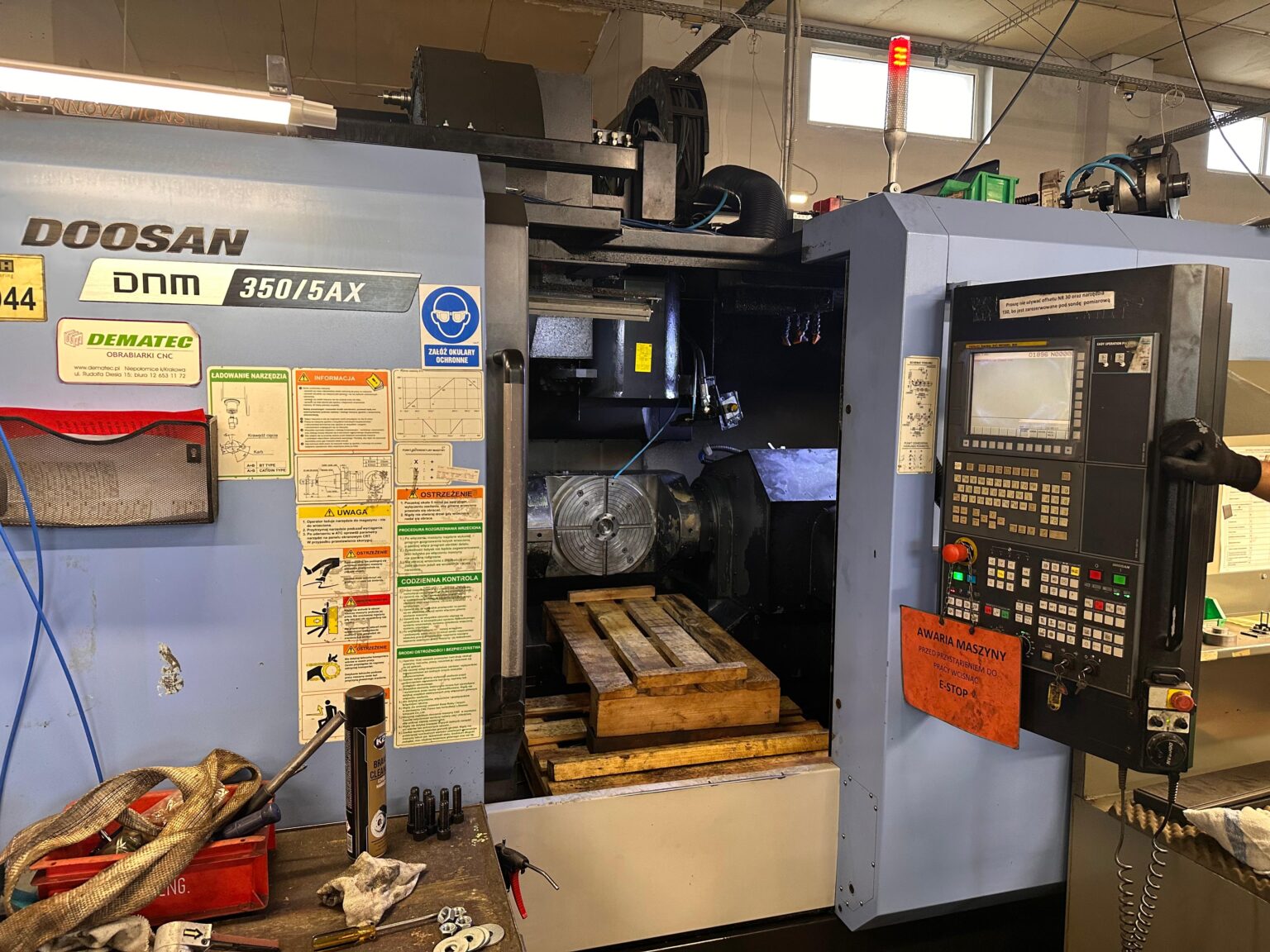

Spindle removal and installation

of CNC spindles and electrospindles

Spindle removal and installation – minimizing risk, maximizing precision.

Professional spindle disassembly and reassembly are key stages of any service intervention. Improper handling can lead to misalignment, tool holding issues, or permanent spindle damage.

At BMS Spindle Service, we perform safe removal and installation of spindles and electrospindles in CNC machines – both during scheduled replacement and repair operations. Each step is preceded by thorough diagnostics, and final assembly is carried out with the highest precision and calibration procedures.

Thanks to the experience of our technicians and our technical facilities, we guarantee short downtimes, optimal spindle-to-machine fitting, and stable machining performance after installation.

Why proper spindle installation

is essential for precision and machine longevity

The spindle is one of the most critical components of a CNC machine – its precise installation directly affects the accuracy of the entire production. Even minor installation errors can lead to costly breakdowns and quality issues.

Improper spindle installation or removal can result in:

- Damage to bearings and spindle taper – excessive axial forces or incorrect seating accelerate wear.

- Spindle geometry errors – causing tool clamping issues and loss of alignment.

- Vibrations and noise during operation – negatively affecting machining quality and component durability.

Professional spindle removal and installation ensure smooth, quiet, and precise machine operation – without the risk of damage and with full compliance to the machine’s technical parameters.

CNC spindle removal and installation

step by step

Each spindle removal and installation at BMS Spindle Service is carried out according to a systematic, multi-step procedure that adheres to the highest safety standards. This ensures precise alignment of the spindle with the machine, eliminating the risk of damage, misalignment, or failure during operation.

Most common spindle removal and installation problems

and how we solve them

Loss of clamping force after installation

Improperly seated components may reduce tool stability.

Solution – We verify clamping force and adjust spindle parameters.

Geometry issues after installation

Incorrect spindle alignment leads to poor tool clamping and loss of accuracy.

Solution – We perform full calibration and alignment tests – spindle geometry alignment.

Frequently

asked questions

Safe spindle removal and installation

with guaranteed precision

Entrust the spindle removal and reinstallation to experienced technicians – ensuring proper alignment, cleanliness, and machine safety.

-

Professional handling of all spindle types

-

Minimized risk of damage

-

Service available across all of Europe

Request a quote