Precision CNC

electrospindle service

CNC electrospindle service – mechatronic precision and certified quality.

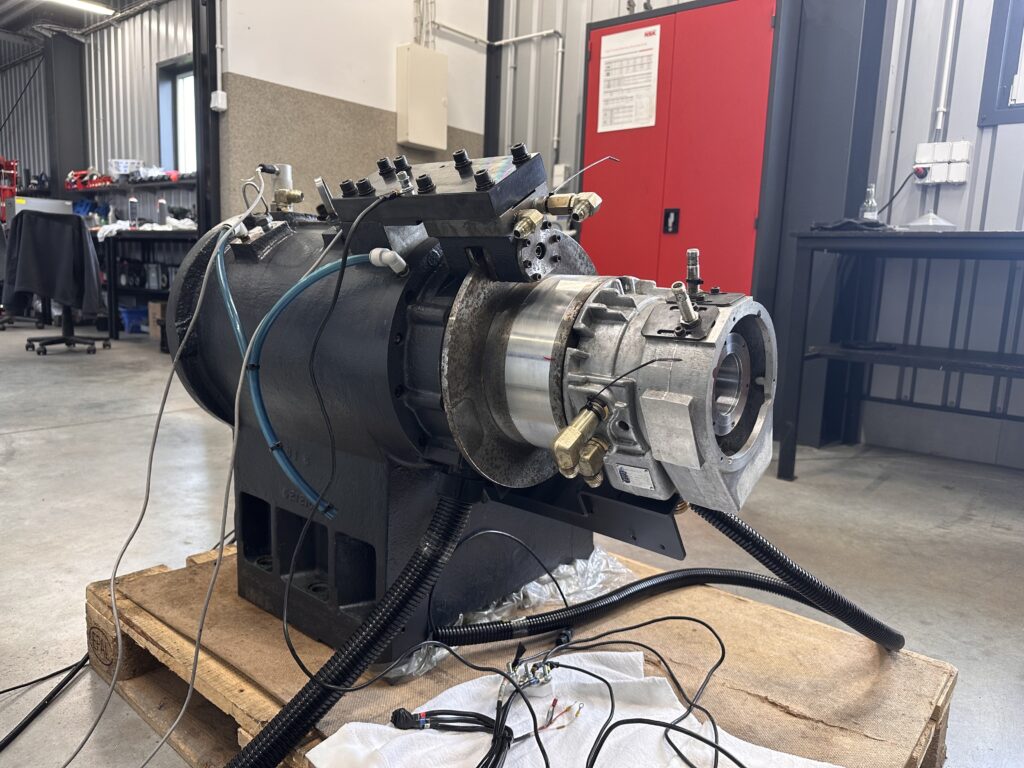

Electrospindles are integrated units combining spindle mechanics, electric drive, and control electronics – the heart of high-speed CNC systems.

They require a specialized approach that merges mechatronic knowledge with hands-on repair experience.

At BMS Spindle Service, we offer comprehensive electrospindle repair, including advanced diagnostics, disassembly, cleaning, bearing and seal replacement, taper repair, precise dynamic balancing, and final performance tests. This allows us to restore full reliability to electrospindles used in woodworking, aluminum machining, and high-frequency systems.

Our services are backed by a 6-month warranty, and with certified procedures and components, we deliver operational parameters that meet or exceed OEM standards. It’s a service that truly extends CNC machine lifespan and minimizes production downtime.

Why CNC electrospindle service

is essential for reliability and efficiency

The electrospindle is the heart of a modern CNC machine – combining a motor, tool clamping system, and control electronics. Its failure affects not only rotation, but also heat dissipation, machining accuracy, encoder signals, and synchronization.

Timely electrospindle service allows you to:

- Eliminate overheating and electrical short circuits – protection against winding and insulation damage.

- Restore accurate encoder signal – crucial for precise positioning.

- Avoid costly, unplanned downtime – efficient service minimizes failure risk.

- Extend the lifespan of rotor, stator, and ceramic bearings – saving on parts and repairs.

- Reduce noise and vibration – refurbishment and balancing improve machine performance.

- Save on OEM electrospindle replacement – service offers faster turnaround and significantly lower cost.

Professional electrospindle repair restores factory parameters and prepares the system for continued, safe operation.

CNC electrospindle service

step by step

Electrospindle refurbishment requires a precise approach – it covers both mechanical and electrical components. Thanks to our repair procedures, we can restore full functionality and durability of high-frequency spindles.

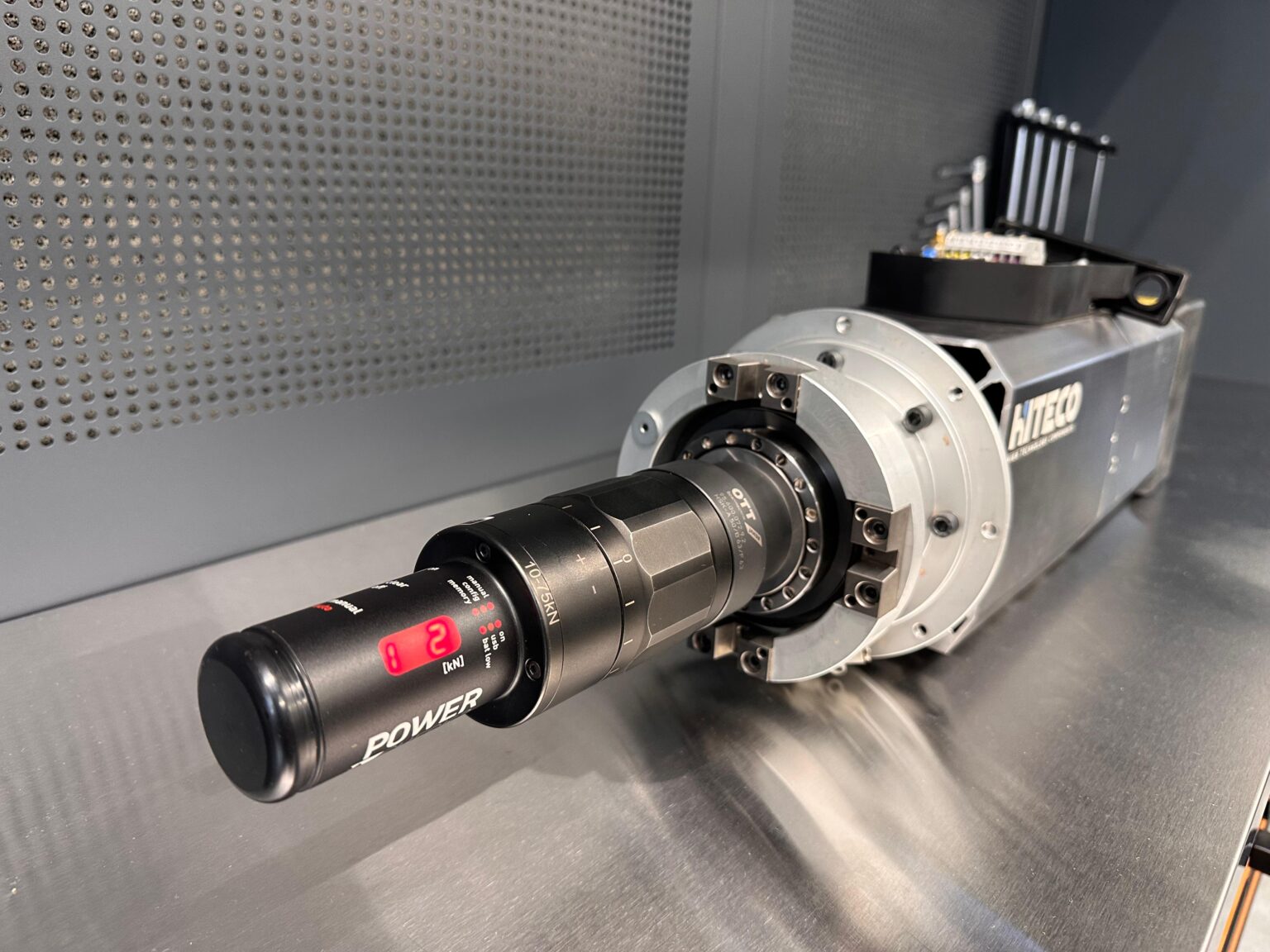

The initial diagnostics include:

- measurement of tool clamping force, noise, vibration, axial and radial runout,

- preliminary temperature and thermal behavior analysis,

- inspection of encoder, sensors, and wiring,

- verification of malfunction symptoms reported by the machine operator.

Thanks to precise analysis at this stage, we can identify the potential causes of failure and plan further repair actions.

This stage includes:

- disassembly of rotor, stator, bearings, sensors, and encoder,

- ultrasonic cleaning of components and removal of grease and coolant residues,

- disinfection, drying, and inspection of each part under a microscope,

- labeling and preparation of components for further analysis.

At this point, the spindle components are ready for detailed wear assessment and planning of possible refurbishment or replacement.

During the analysis, we perform:

- resistance and impedance measurements, as well as winding insulation tests,

- encoder operation and signal verification,

- clearance checks and preliminary bearing wear assessment,

- identification of tool clamping system failures (if present).

Based on the measurements, we prepare a detailed service report that defines the scope of further repair steps.

The rewinding process includes:

- removal of old windings and core preparation,

- winding of new copper wire according to OEM specifications,

- impregnation of windings with resin and thermal oven curing,

- testing of phasing, resistance, and insulation integrity.

The rewinding process complies with standards for high-frequency electrospindles and ensures original performance parameters.

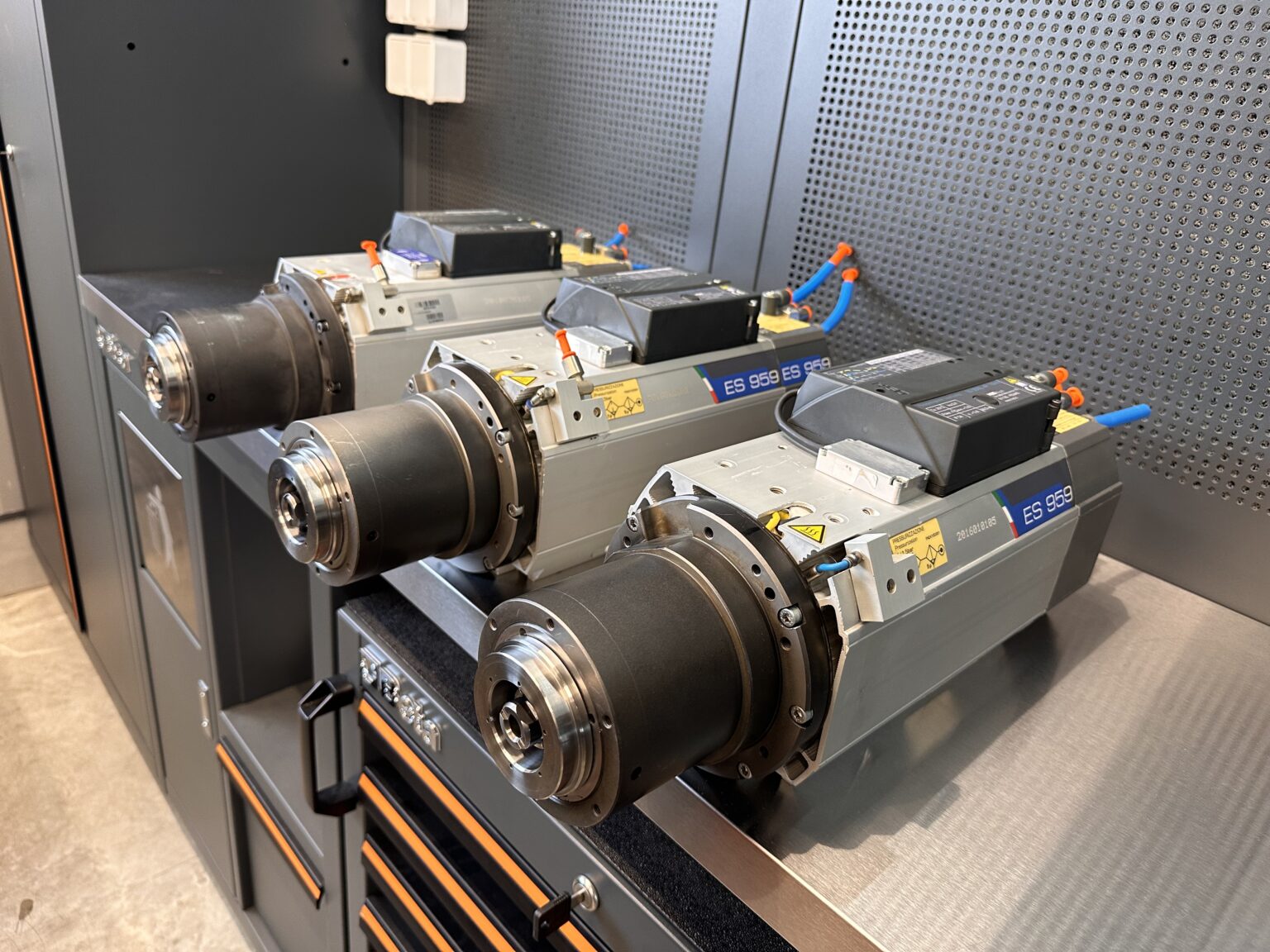

The scope of work includes:

- replacement or refurbishment of sleeves, bearing seats, flanges, and rings,

- installation of new seals, bushings, and tool clamping elements,

- assembly of spindle bearings in accordance with the manufacturer’s specifications,

- precise fitting of components according to OEM documentation.

All components are assembled in controlled conditions, maintaining tolerances compliant with industrial standards.

As part of the refurbishment, we perform:

- precision grinding to remove microdamage and restore geometry,

- chrome plating of the taper surface to improve wear resistance,

- adjustment of taper angles in accordance with tool specifications,

- restoration of taper alignment and concentricity with the spindle axis.

Proper taper refurbishment ensures stable and precise tool clamping, which is crucial for CNC machining quality.

This stage includes:

- balancing the rotor across full speed range – low, medium, and high RPMs,

- using CIMAT stations for real-time vibration analysis,

- achieving ISO balance class G0.4 or better,

- minimizing vibration and noise caused by imbalance.

A properly balanced assembly ensures stable operation even above 30,000 RPM.

The procedure includes:

- positioning the encoder (optical or magnetic) relative to the spindle axis,

- phasing the encoder with the stator windings,

- signal testing – phase alignment, waveform, and readings across full RPM range,

- calibrating temperature, speed, and clamping force sensors (if present).

Proper encoder setup ensures accurate spindle control and full synchronization with the machine drive system.

During the test, we check:

- electrospindle operation at different speeds and temperatures,

- vibration amplitude and noise level,

- encoder signal quality and phase alignment accuracy,

- clamping force and stability of all sensor systems.

This stage confirms that the electrospindle is fully ready for production use and all systems function according to specification.

The full set of documents and protection includes:

- dynamic balancing certificate (ISO G0.4 or better),

- electrical and mechanical test report,

- measurement charts and calibration reports,

- confirmation of compliance with OEM parameters,

- warranty card – 6 months on all replaced components and performed work,

- electrospindle transport protection (bubble wrap, foam, reinforced box or crate).

The electrospindle is now ready for safe transport – with full documentation and service warranty.

During the geometry calibration, we perform:

- measurement and correction of spindle axis position relative to the machine’s guide system,

- alignment of the spindle angle relative to the working table surface,

- verification of coaxiality and proper tool engagement angle,

- axial accuracy tests to ensure precision machining operations.

Thanks to this calibration, the electrospindle operates in line with the machine’s geometry, ensuring maximum CNC machining accuracy.

Most common electrospindle problems

and how we solve them

Electrospindle vibrations at high speeds

Worn spindle bearings, incorrect balancing, or improper assembly of rotating components.

Solution – Dynamic balancing and bearing replacement effectively eliminate vibrations and restore operating stability.

Electrospindle overheating

Inefficient lubrication system, damaged seals, or malfunctioning coil cooling mechanism.

Solution – Seal replacement, lubrication system refurbishment, cleaning of cooling channels, and temperature sensor inspection.

Loss of torque / unstable motor operation

Motor winding damage, overheating, short circuits, or encoder issues.

Solution – Electrospindle rewinding according to the original specification and post-repair testing.

Uneven tool runout

Worn spindle taper, misaligned tool mounting, or weakened clamping force.

Solution – Spindle taper grinding and clamping force calibration restore mounting precision and eliminate runout.

Frequently

Asked Questions

Trust the electrospindle experts

and restore full performance

We repair electrospindles quickly, precisely, and with a warranty – regardless of the brand or machine type.

-

12-month service warranty

-

Express turnaround times

-

Serving customers across Europe

Request a quote