Spindle and electrospindle balancing – the key to precision and longevity

In the world of CNC machining, precision and reliability are crucial. One of the most important – and often underestimated – elements of keeping a spindle in excellent condition is dynamic balancing. Whether we are dealing with a classic spindle or an electrospindle, balancing affects the accuracy, durability, and safety of the entire machine’s operation.

Neglecting this stage may result not only in reduced machining quality but also in serious mechanical failures that generate high service costs and production downtime. That’s why balancing should be treated as a key element of every professional spindle repair.

What is

spindle balancing

Spindle balancing is the process of equalizing rotating masses to minimize vibrations and centrifugal forces generated during operation.

Even minimal unbalanced mass at speeds of 10,000 – 24,000 rpm can lead to:

- excessive bearing wear,

- reduced machining quality,

- tool damage,

- increased noise and operating temperature,

- vibrations transferred to the machine structure,

- misalignment of CNC machine geometry.

Why CNC spindle balancing

is so important

The spindle is the heart of every CNC machine. An unbalanced spindle generates uncontrolled vibrations that affect not only machining quality but also directly impact the lifespan of the machine.

Proper balancing allows you to:

- reduce vibrations to a minimum,

- extend the lifespan of bearings and other rotating components,

- maintain high surface quality of machined parts,

- lower service costs and prevent unexpected failures,

- improve operator safety,

- ensure dimensional stability and repeatable production.

How the balancing process

works

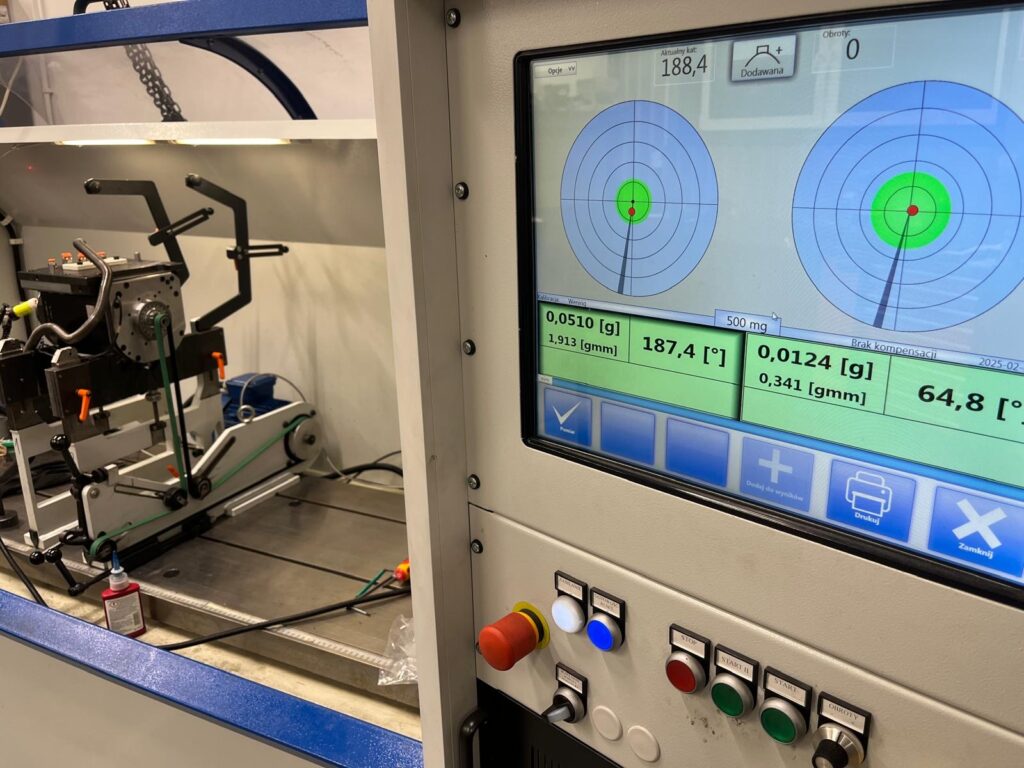

In our service, we use an advanced CIMAT balancing machine, which allows for precise spindle balancing in a class of accuracy as fine as 0.4G.

The process includes:

How often should spindle balancing

be performed

We recommend performing balancing:

- after each regeneration or bearing replacement,

- when excessive vibrations or noise occur,

- after collisions, impacts, or tool changer replacement,

- preventively once a year as part of the machine's technical inspection,

- after replacing the taper, rotating elements, or repairing the spindle drive.

Summary

CNC spindle balancing is an investment in quality, safety, and machine longevity.

Skipping this step can lead to costly failures and deterioration of machining parameters, especially at high speeds and with tight tolerances.

Take care of your machine – entrust professional spindle balancing to the experts at BMS SPINDLE SERVICE CNC. Each balancing process is confirmed with a detailed protocol, ensuring the highest quality of service.