HSD ES 779L Spindle Repair – Complete CNC Service

Specification

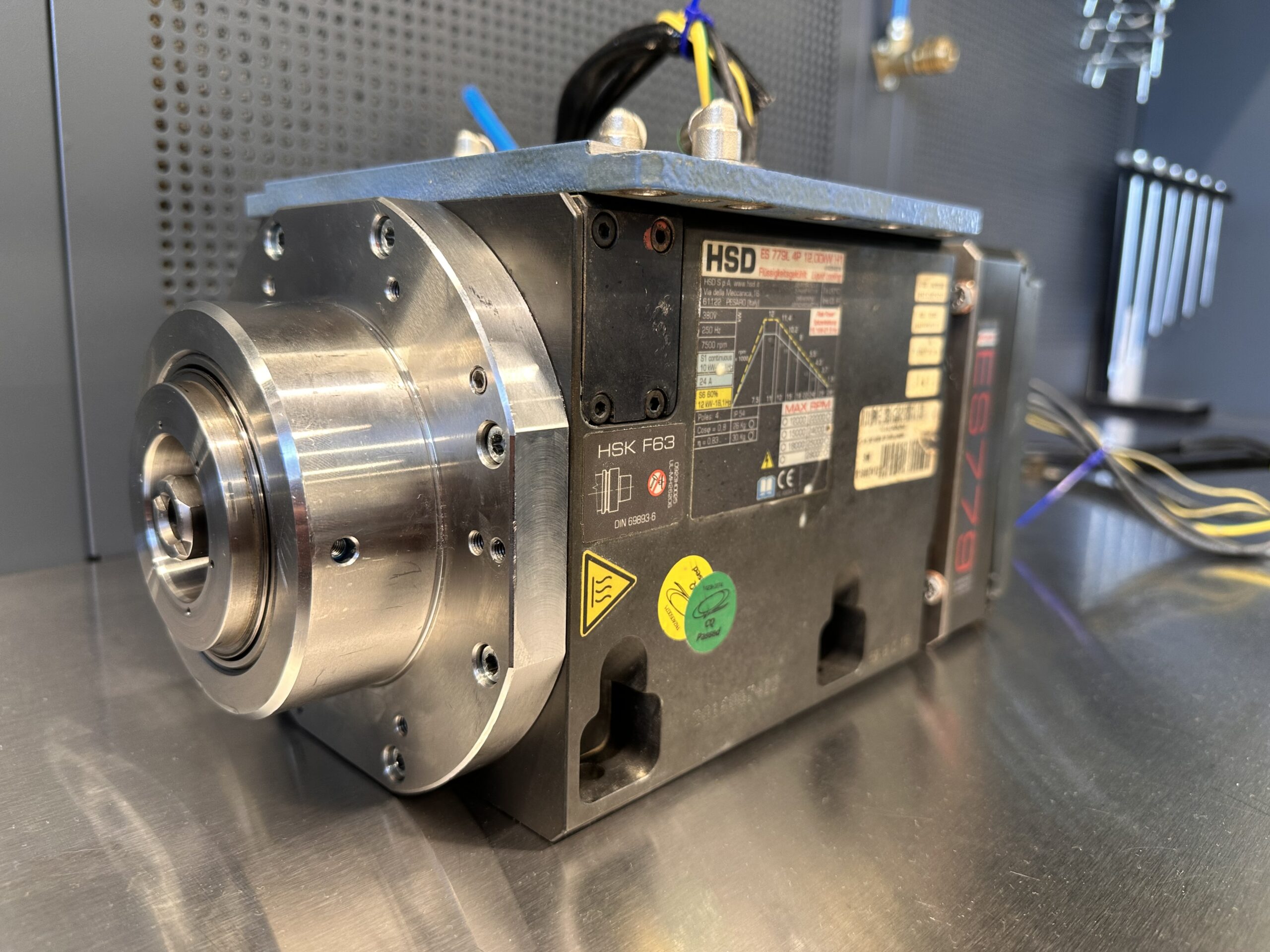

Model: HSD ES 779L

Tool holder taper: HSK 63F

Rotational speed: 24,000 rpm

Machine: 5-axis machining center FANUM

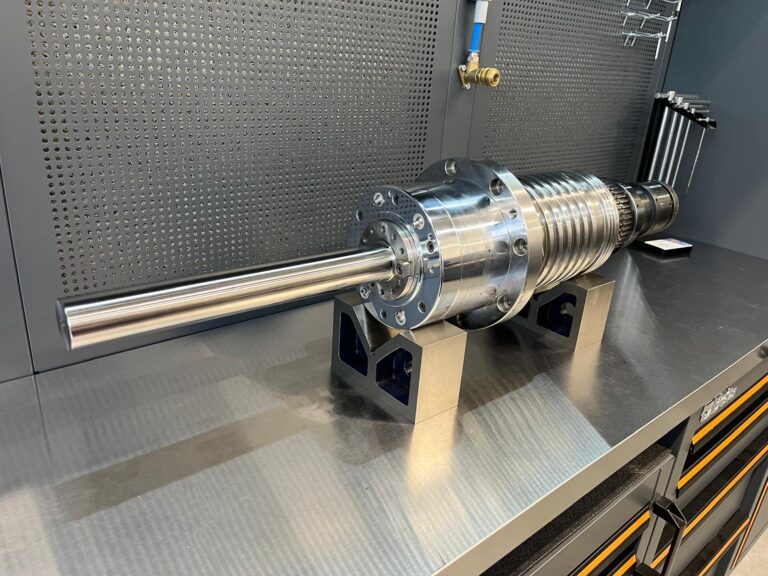

The HSD ES 779L electrospindle, operating in a 5-axis FANUM machining center, was delivered to our service. The order included a full service package: from rapid disassembly to repair, reassembly, and thermal analysis. We carried out the service door to door, ensuring maximum convenience and time savings for the client.

Express disassembly

and free fault analysis

Our service team disassembled the spindle the next business day after the service request. We performed a free technical analysis that revealed severe internal damage.

The diagnosis revealed:

- worn ceramic spindle bearings,

- damaged HSK 63F taper,

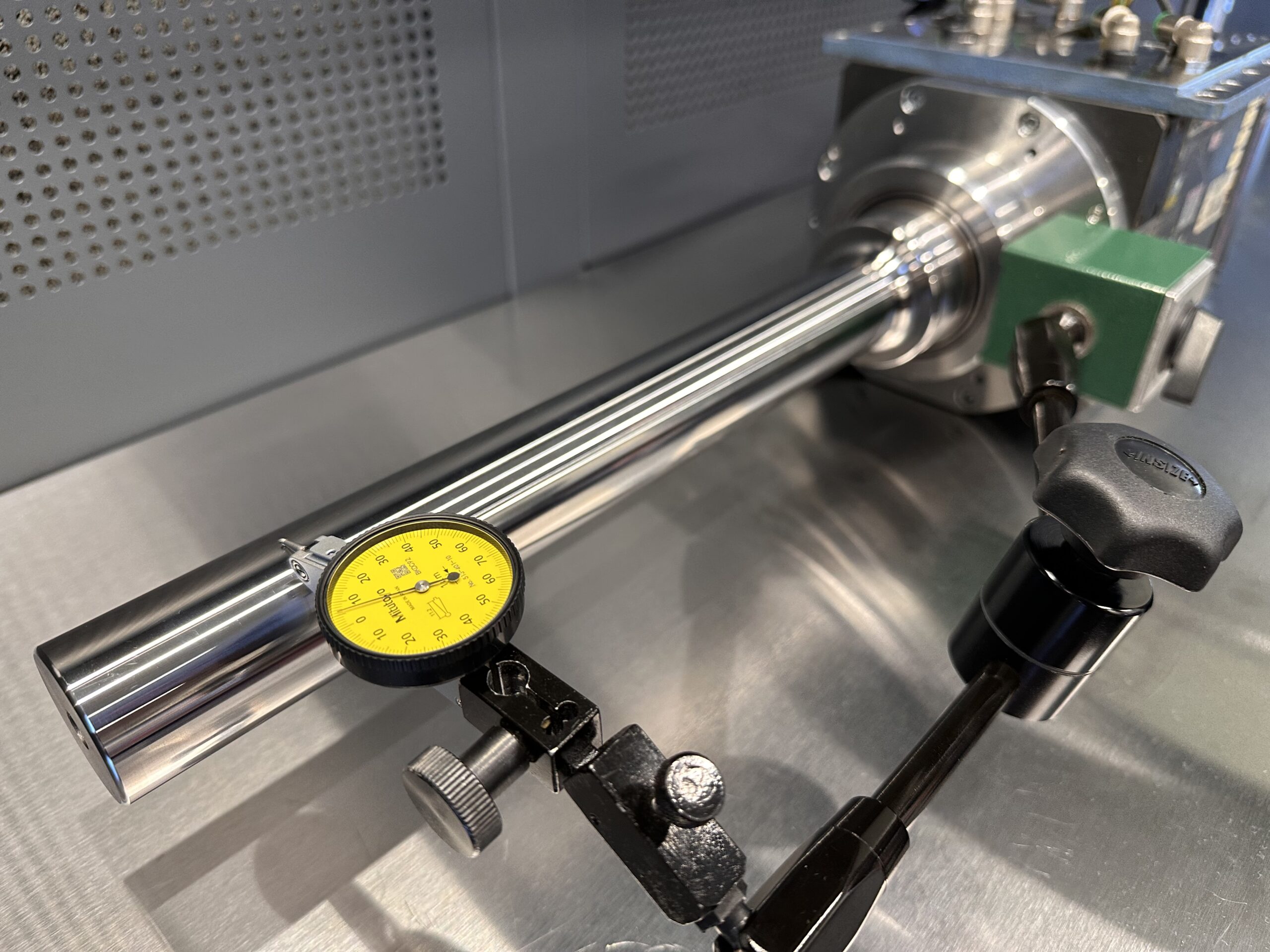

- negative tolerance of the rear bearing housing and rotor mounting surface,

- missing one of the inductive speed sensors.

Repair stages of

HSD ES 779L electrospindle

Installation

and completion

The repaired HSD electrospindle was delivered and installed the next day after all work was completed. Thanks to efficient logistics and preassembled parts, the entire regeneration process was completed quickly and without production downtime.

Quality guarantee

and durability

The regeneration was a complete success – the spindle regained full functionality, factory-level precision, and is now ready for industrial use.

As always, the entire process was documented and covered by our full service warranty. Contact us – BMS CNC SPINDLE SERVICE – if your HSD electrospindle needs professional help!