HOMAG Spindle Repair and Service

We specialize in repairing HOMAG spindles – a renowned manufacturer of CNC machines for woodworking and wood-based materials. Our service ensures the highest quality standards and a comprehensive approach to spindle refurbishment.

HOMAG

spindles

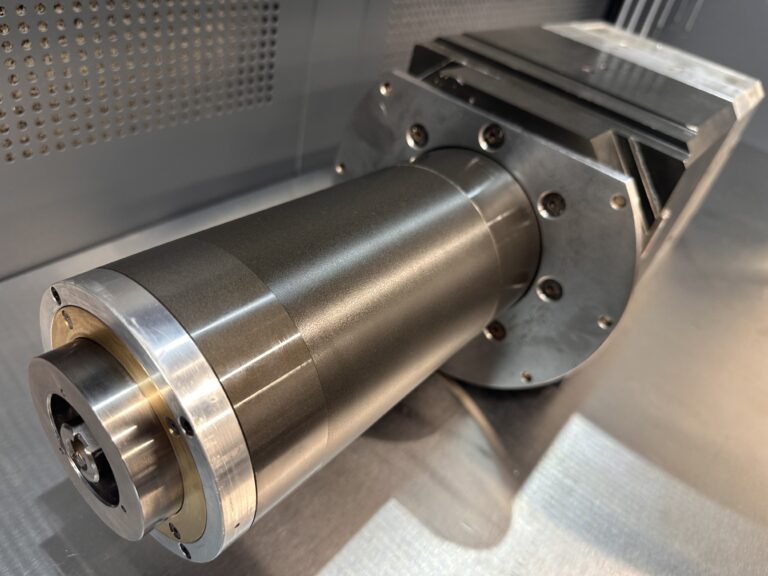

HOMAG spindles are advanced electrospindles installed in machining centers used in the furniture and woodworking industries. They are known for their reliability, high precision, and compatibility with production lines.

Despite their quality, HOMAG spindles may show signs of wear after extended use. Common issues include vibrations, noise, overheating, or sensor errors. Our service ensures full restoration of the spindle’s operating parameters.

Case studies

repair of Homag spindles

HOMAG BIZ 411 Spindle Repair – HSK 63F Taper

The scope covered a full HOMAG spindle overhaul from a BIZ 411 machine, rated for 24,000 r...

Read more

Express repair of HOMAG SKF electrospindle from Weeke Venture 1M – just 5 days!

An HOMAG SKF electrospindle, mounted in a Weeke Venture 1M CNC machine used for daily furn...

Read more

HOMAG / SKF 4-075-03-0615 Electrospindle Repair

The electrospindle was collected directly from the customer, located approximately 200 km ...

Read moreProfessional HOMAG spindle service

step by step

We repair HOMAG spindles in accordance with the original manufacturer standards. The process includes thorough diagnostics, mechanical refurbishment, and load testing.

Symptom verification

Spindle disassembly

Cleaning and inspection

Component testing

Parts replacement

Dynamic balancing

Final tests

HOMAG electrospindle rewinding

We service popular HOMAG spindles used in machining centers, including ATC electrospindles cooled by liquid or air. We guarantee full OEM specification compliance.

Need a repair for your

HOMAG spindle

Contact our service – we’ll prepare an individual quote, suggest a schedule, and provide technical support. We serve all of Poland and Europe.

Contact us today – you’ll receive expert advice and reliable service.

CONTACT