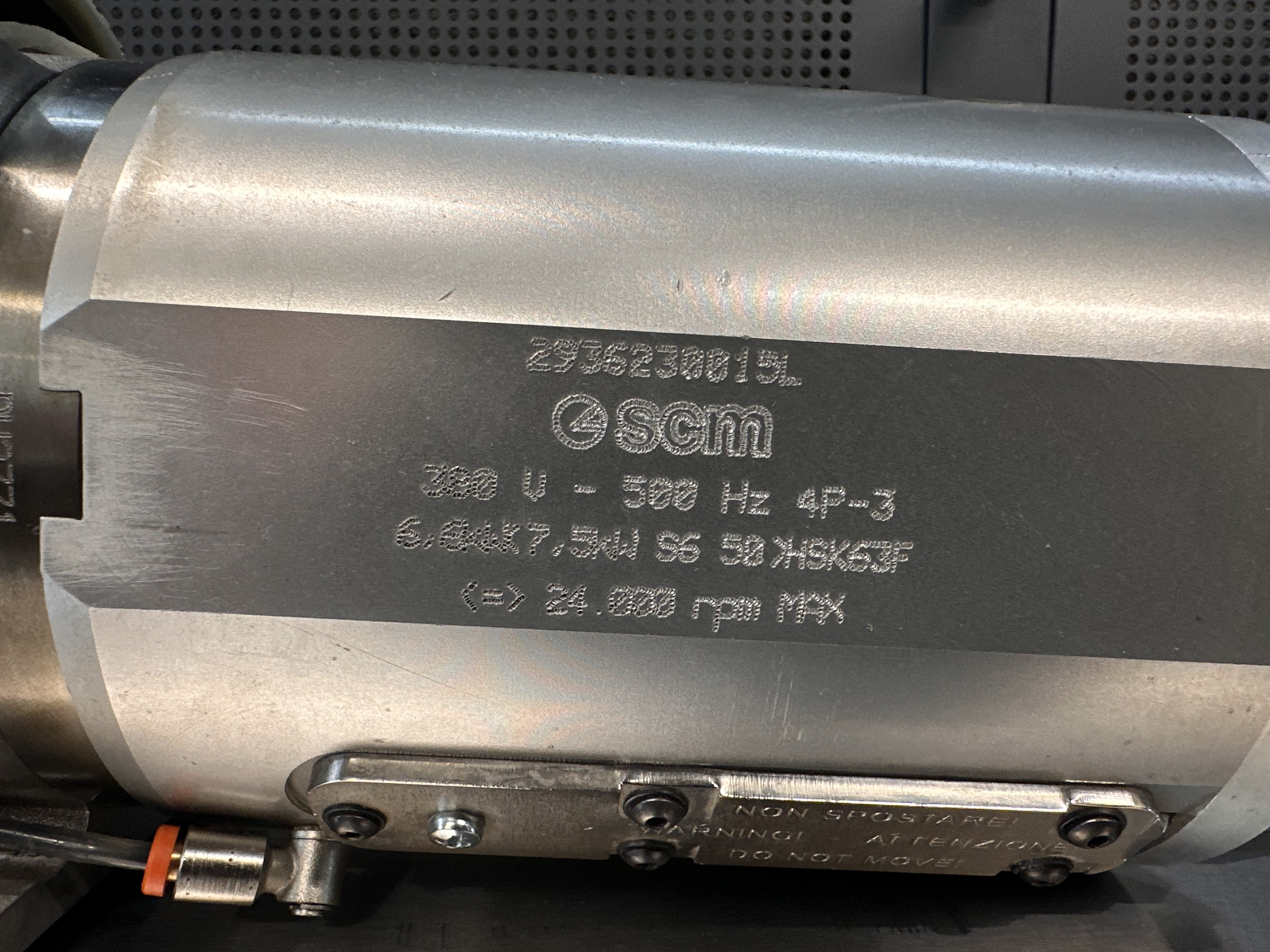

SCM 2936230015L Spindle Repair in 4 Days

-

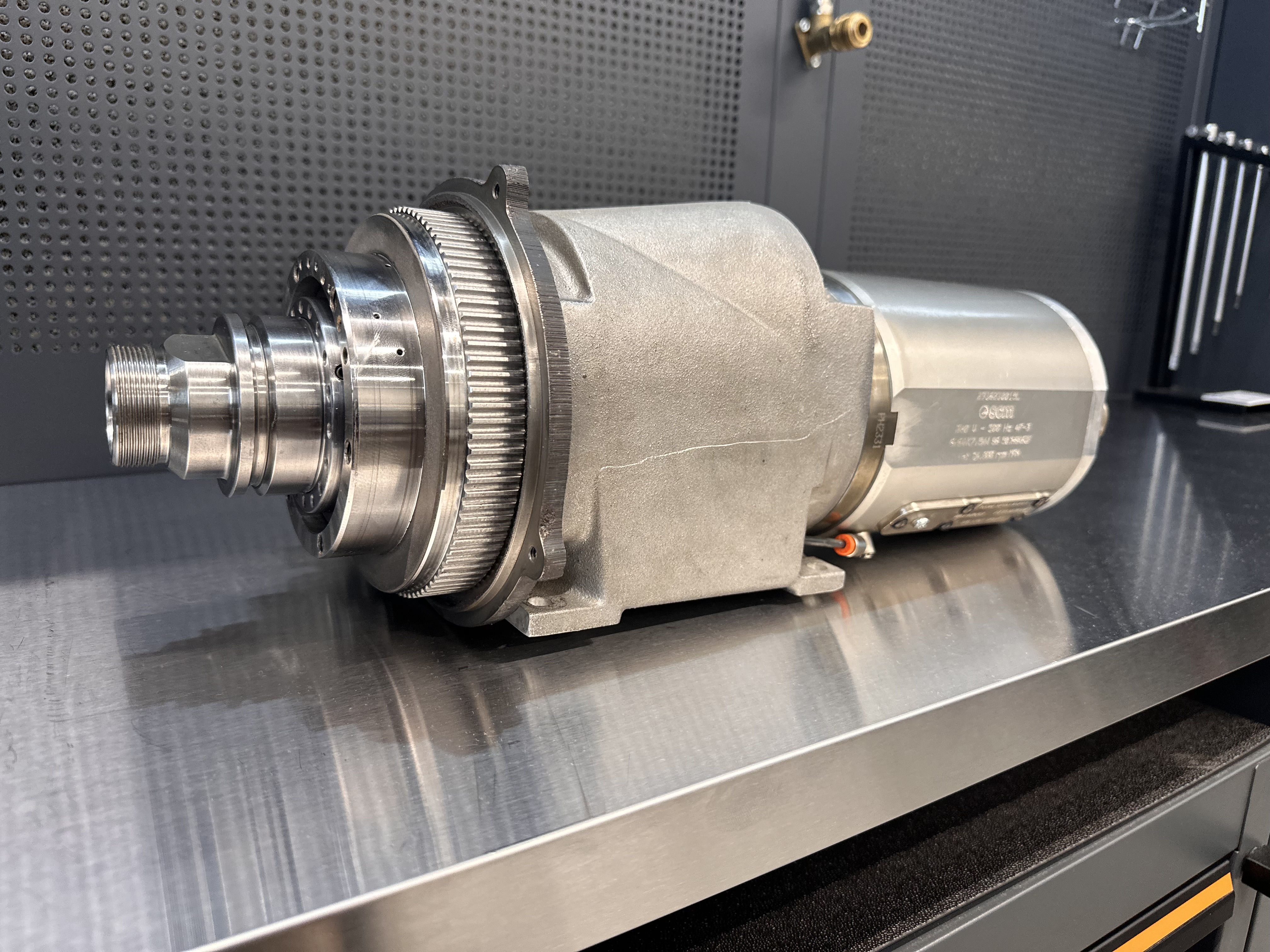

Spindle manufacturer: SCM

-

Model: 2936230015L

-

Spindle speed: 24 000 rpm

-

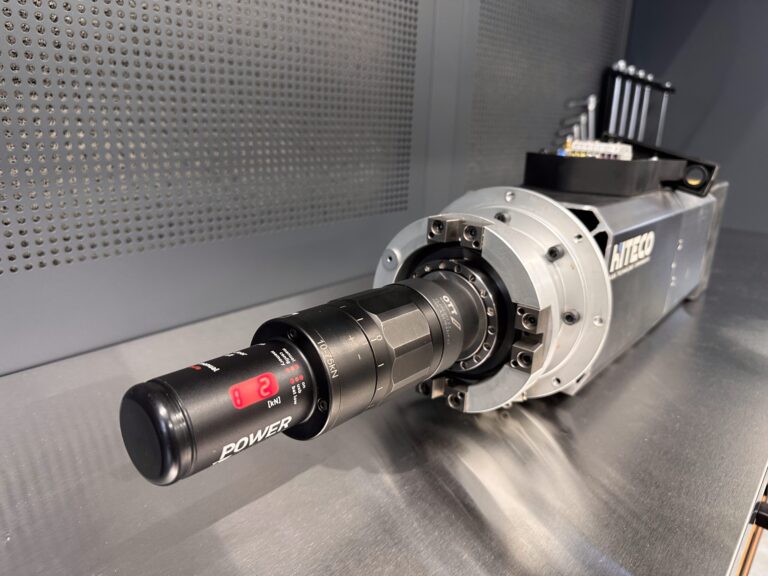

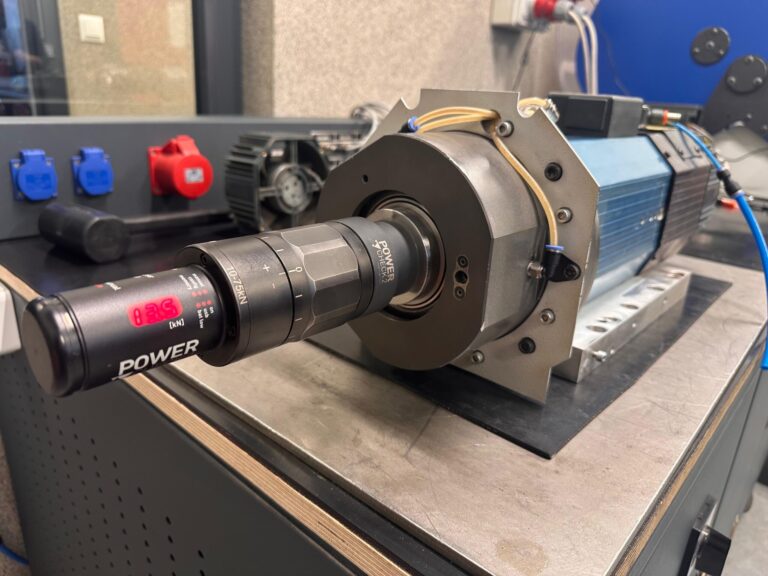

Taper: HSK 63F

-

Logistics: door-to-door pickup and delivery from Krakow

A SCM 2936230015L spindle with HSK 63F taper and up to 24 000 rpm reached our service. The customer faced an unplanned downtime, so the job was marked as urgent — the priority was to restore full functionality fast. The entire process — from pickup to return — was completed in 4 days, minimizing production losses to the absolute minimum.

Diagnostics

and condition check

The spindle required immediate intervention due to typical symptoms of bearing wear and degraded tool holding quality: increased noise during operation, reduced repeatability, and visible wear marks on the taper. The customer requested an express, complete repair while maintaining parameters for 24 000 rpm plus full logistics support.

Scope of work

for SCM spindle repair

The above operations are the core of an effective repair for this spindle class and quickly restore parameters required for stable, precise high-speed operation.

Result

and production benefits

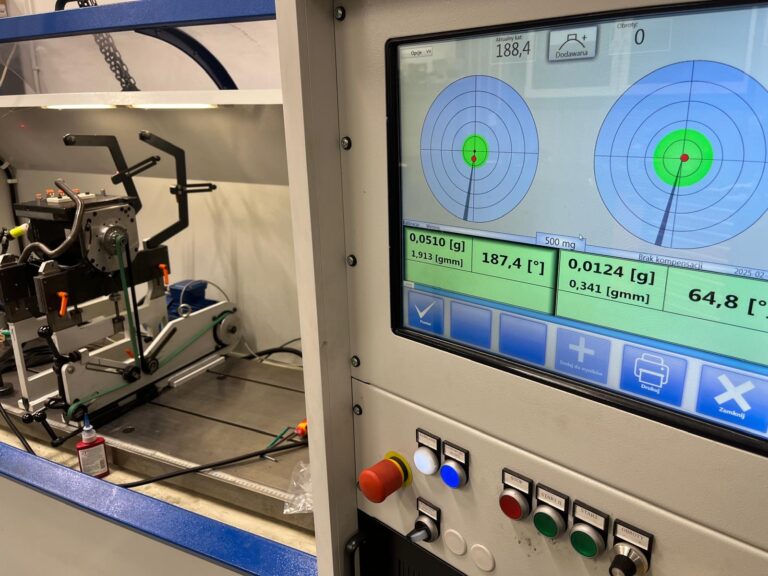

After the repair, the SCM 2936230015L spindle runs stably across the full speed range, and tool clamping repeatability is restored thanks to the refreshed HSK 63F taper and the new drawbar springs. Lower vibration and better geometry translate into improved surface finish, longer tool life, and less sensitivity to process variations and micro-stoppages. In “express” mode, all work was performed with no compromise on quality.

When to plan

a full service

If you notice similar symptoms on your machine — noise, vibration, marks on the HSK 63F taper or a drop in clamping force — don’t postpone it. Bearing replacement, taper restoration, drawbar refresh, and cleaning in one coherent process delivers the best effect and genuinely lowers production costs. We can help you run such a service from A to Z.

Have a similar case?

Contact us

Do you need express SCM spindle repair with HSK 63F — from removal, through taper restoration, to precision balancing and clamping force calibration? Write or call us.