KESSLER Spindle Repair on DMG CMX 1100 V

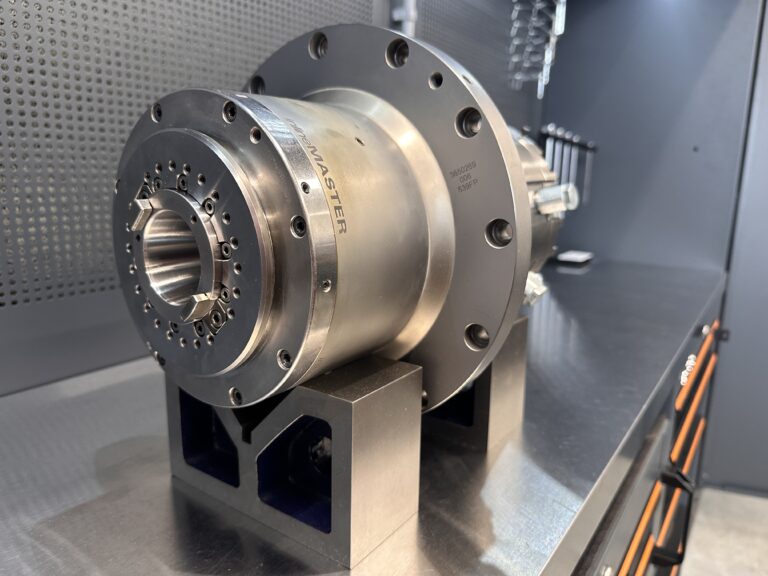

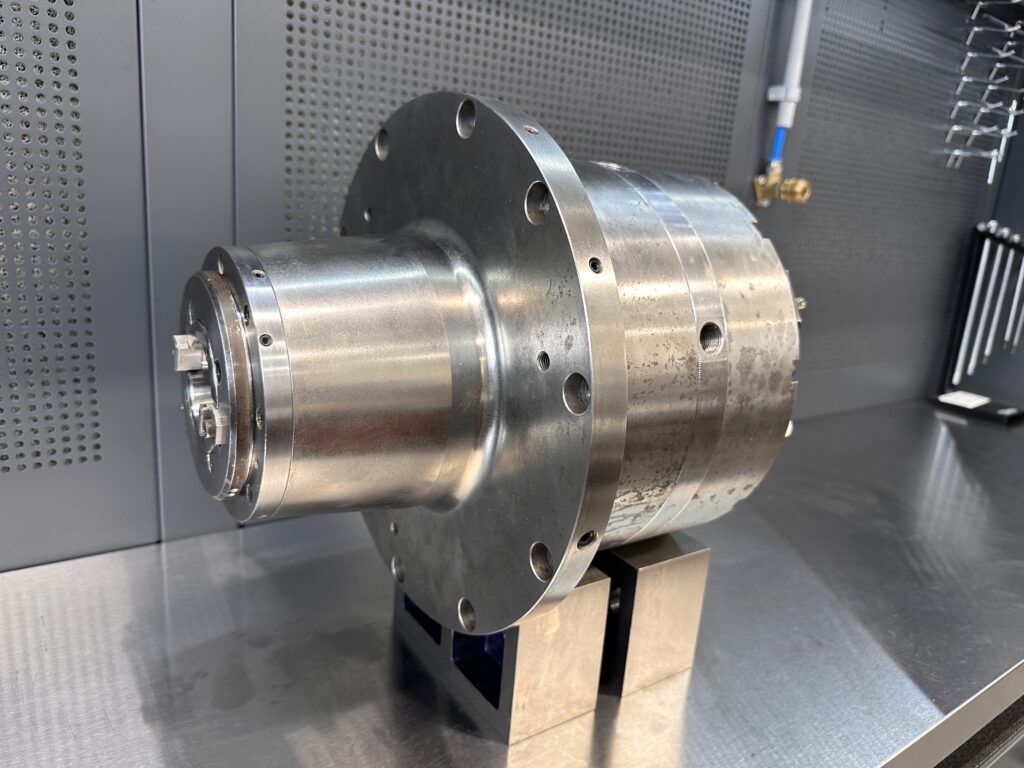

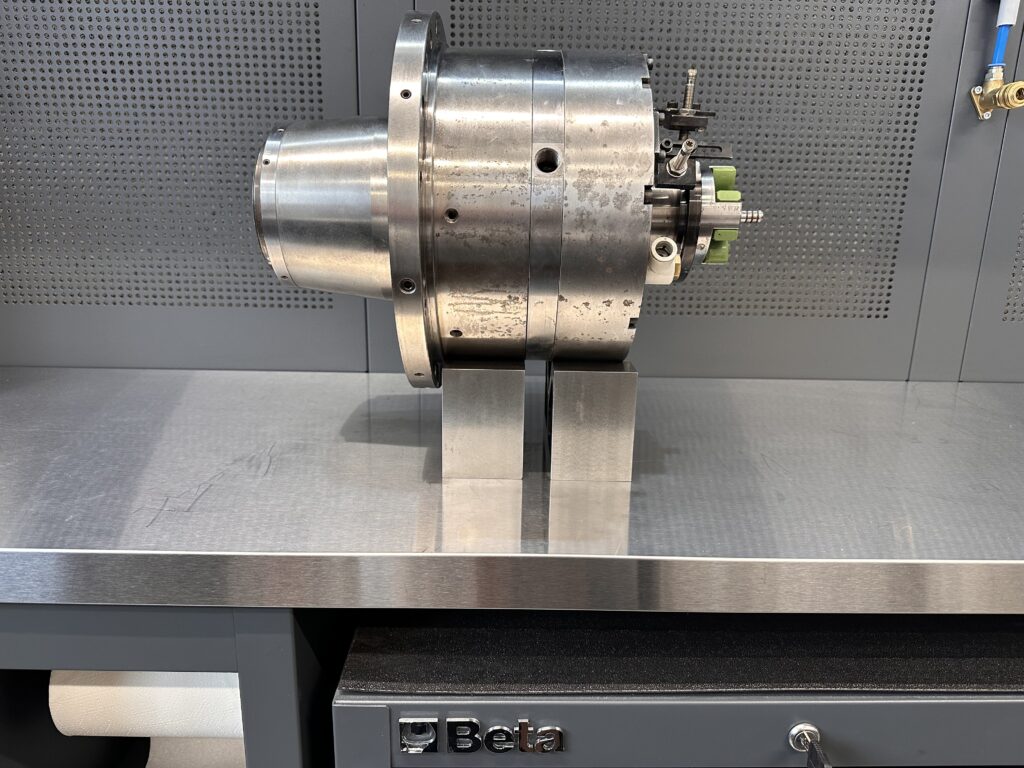

KESSLER spindle overhaul on DMG CMX 1100 V (12,000 rpm, SK40)

-

Spindle manufacturer: KESSLER

-

Machine: DMG CMX 1100 V

-

Spindle speed: 12,000 rpm

-

Taper: SK40

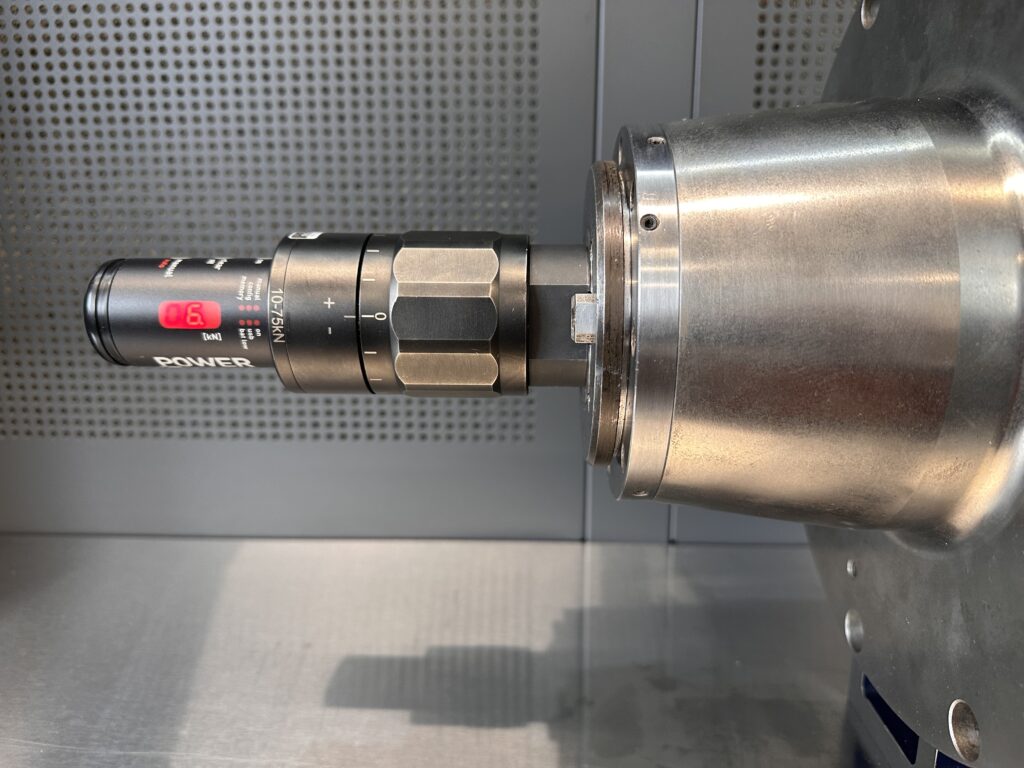

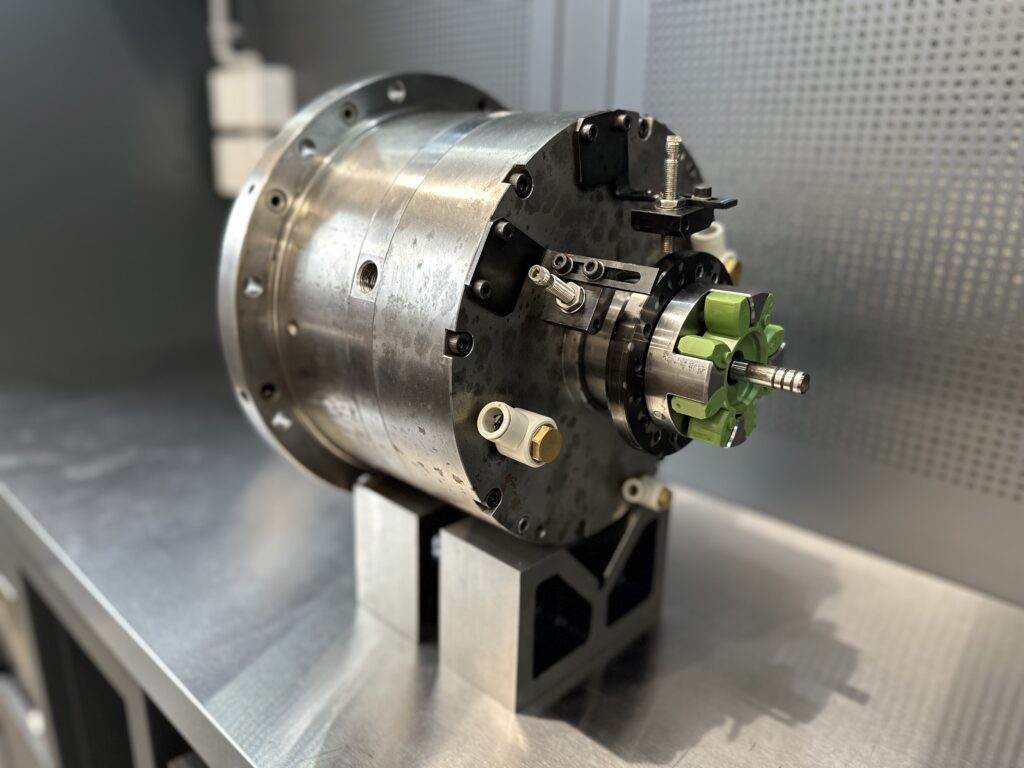

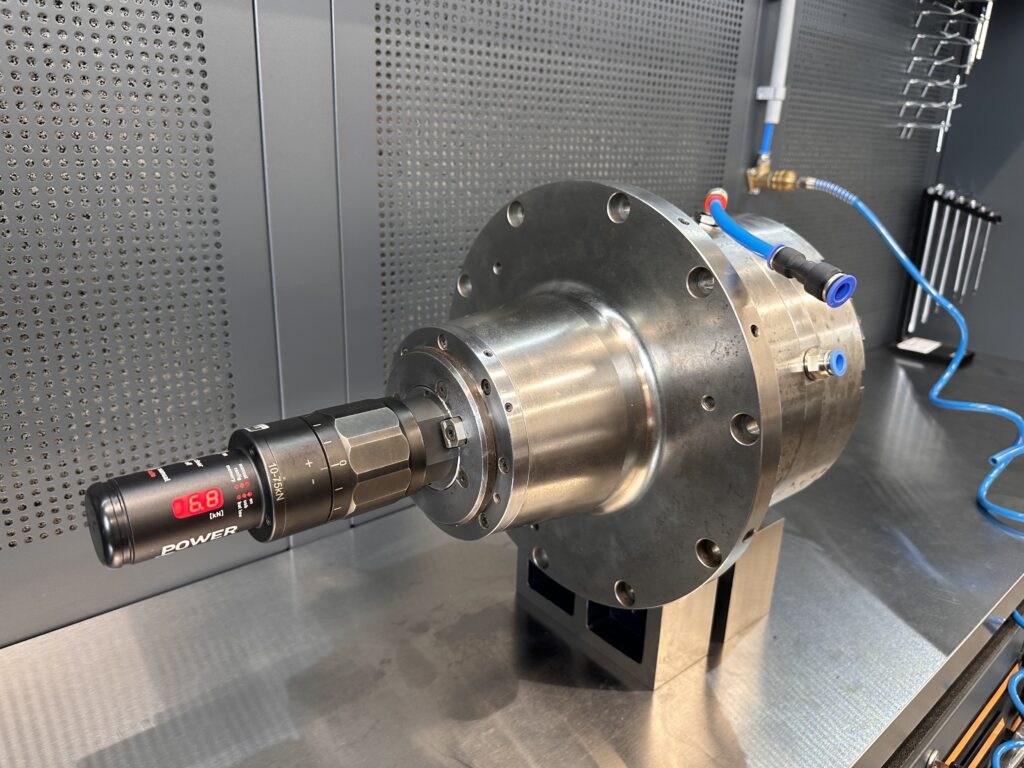

The complete overhaul of the KESSLER spindle in our workshop restored factory precision and process stability to the DMG CMX 1100 V. We delivered a comprehensive service scope including bearing replacement, SK40 taper restoration, installation of a brand-new OEM drawbar assembly, sensor calibration, and replacement of all seals. Additionally, we supported the customer during self-installation of the spindle and helped eliminate the root cause of the previous coolant ingress. The service is covered by a 12-month warranty.

Diagnostics

and verification of the KESSLER spindle condition on DMG CMX 1100 V

Symptoms and initial diagnosis — KESSLER spindle on DMG CMX 1100 V:

- elevated vibration noticeable across the entire speed range,

- signs of overheating on the housing and a decline in surface finish after machining,

- alarming noises at high speeds (up to 12,000 rpm) indicating bearing wear,

- traces of coolant and contamination — the result of machine leaks leading to degradation of internal spindle components.

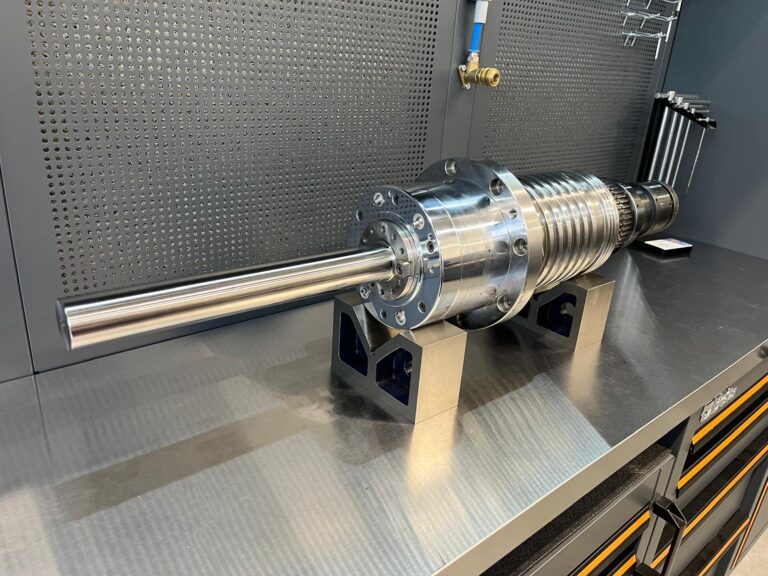

The initial assessment confirmed the need to replace precision spindle bearings and inspect the tool drawbar system. We also checked the bearing seats and evaluated the SK40 taper geometry to rule out defects that could increase runout and transmit vibration to toolholders.

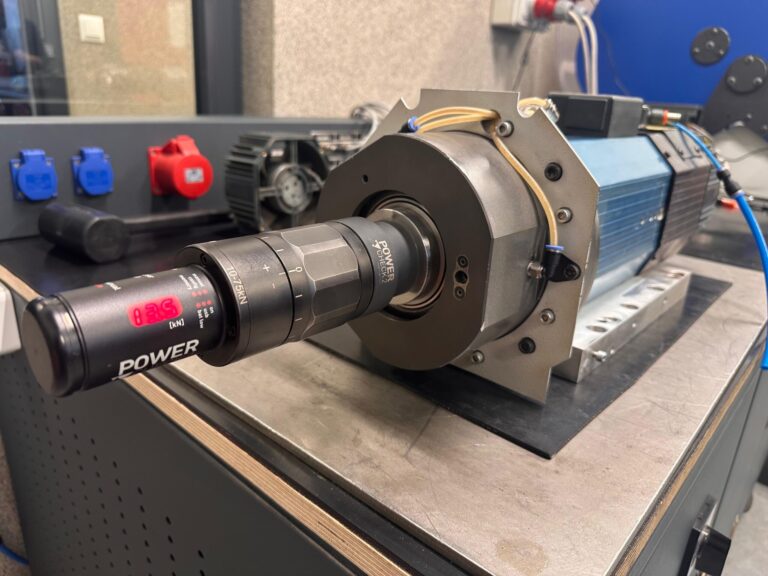

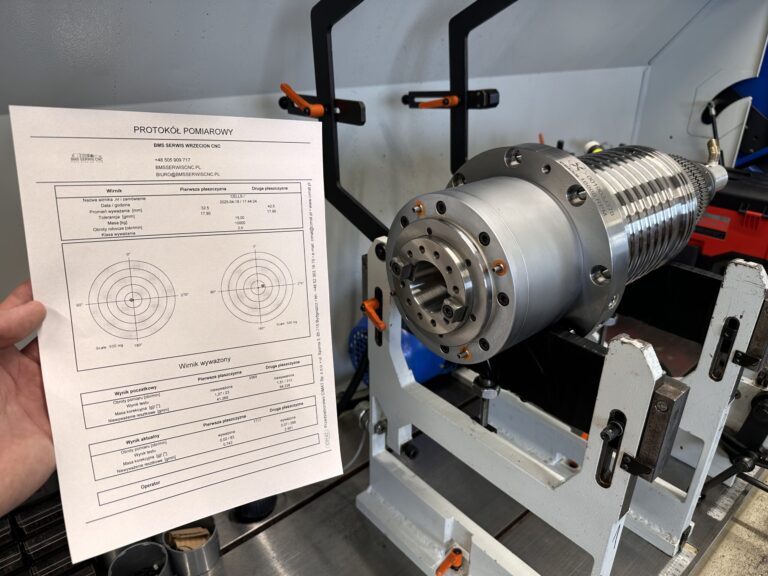

Work scope — step by step

KESSLER spindle repair – DMG CMX 1100 V

Service results

KESSLER spindle – DMG CMX 1100 V

- Significant vibration reduction and stable operation across the full speed range.

- Restored machining precision — improved surface finish and dimensional accuracy.

- Correct tool clamping force — secure SK40 toolholding and longer tool life.

- Resistance to coolant ingress thanks to new seals and improved coolant-system integrity.

On-site customer support

installation and leak elimination

The customer chose to install the spindle independently at their facility. We provided full technical support — detailed installation guidelines, a run-in and warm-up procedure, and consultations to eliminate coolant-system leaks to prevent recurrence of flooding.

Post-service recommendations

KESSLER spindle – DMG CMX 1100 V

- Regularly inspect the machine’s coolant system and seals.

- Follow warm-up recommendations before high-speed operation.

- Monitor vibration and temperature — early response greatly extends bearing life.

- Keep the SK40 taper and toolholders clean (debris may worsen runout and cause micro-damage).

Warranty and responsibility

12 months of service coverage

Our KESSLER spindle overhaul is covered by a 12-month service warranty. The warranty covers workmanship and the parts used, in line with the service protocol provided to the customer.

Summary

stability, accuracy, operational safety

The overhaul restored the KESSLER spindle on the DMG CMX 1100 V to full performance and accuracy required for both serial and precision production. A comprehensive approach — from diagnostics through bearing replacement and SK40 taper restoration to sensor calibration and new seals — delivered a lasting result and safe operation. Additional support in eliminating the leak source minimizes the risk of recurrence.