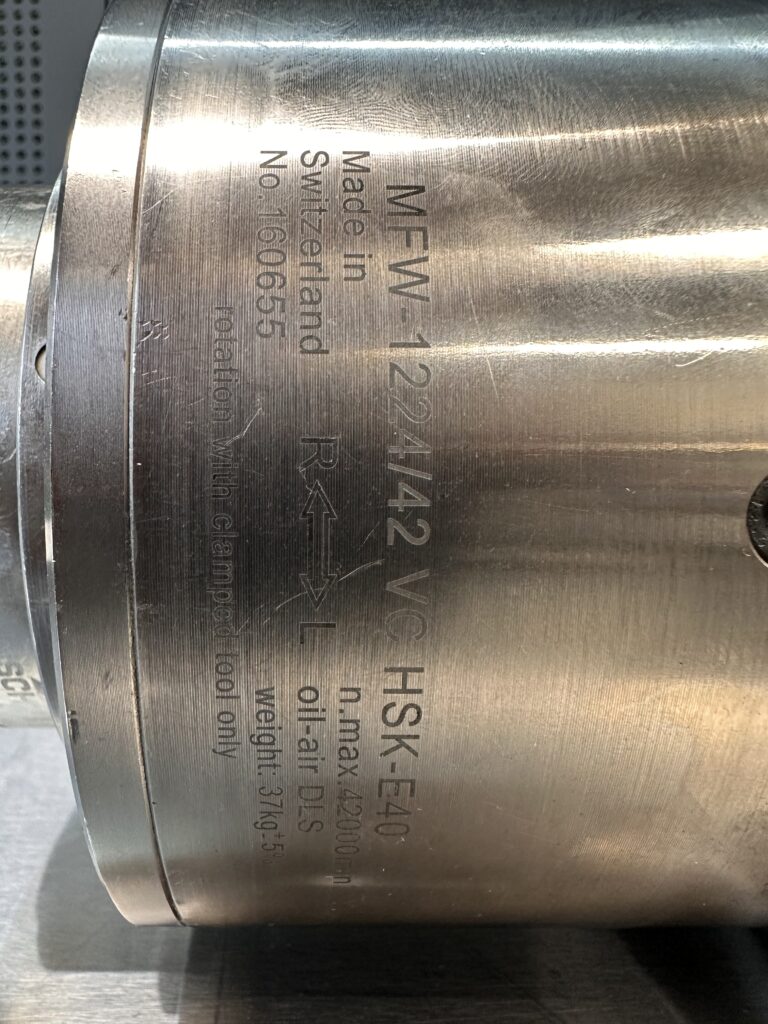

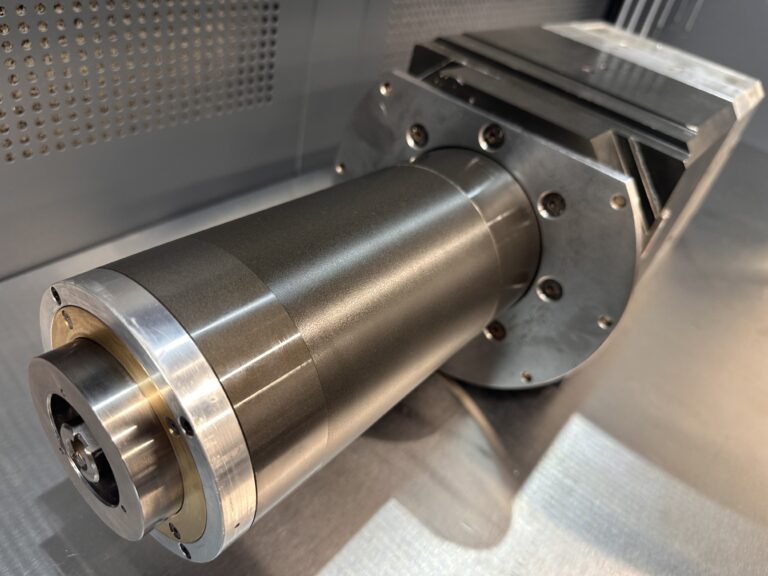

FISCHER MFW-1224/42 VC HSK-E40 electrospindle repair on SPEED HAWK 650

Comprehensive repair of FISCHER MFW-1224/42 VC HSK-E40 electrospindle from SPEED HAWK 650

-

Spindle manufacturer: FISCHER

-

Machine: SPEED HAWK 650

-

Taper: HSK-E40

-

Speed: 42,000 rpm

The FISCHER MFW-1224/42 VC HSK-E40 electrospindle operates in very demanding conditions: rotational speed up to 42,000 rpm, HSK-E40 tool interface and a high-precision SPEED HAWK 650 machining center. Under such parameters even minor wear of the bearings, taper or clamping unit quickly leads to reduced surface quality, increased vibration and shorter tool life.

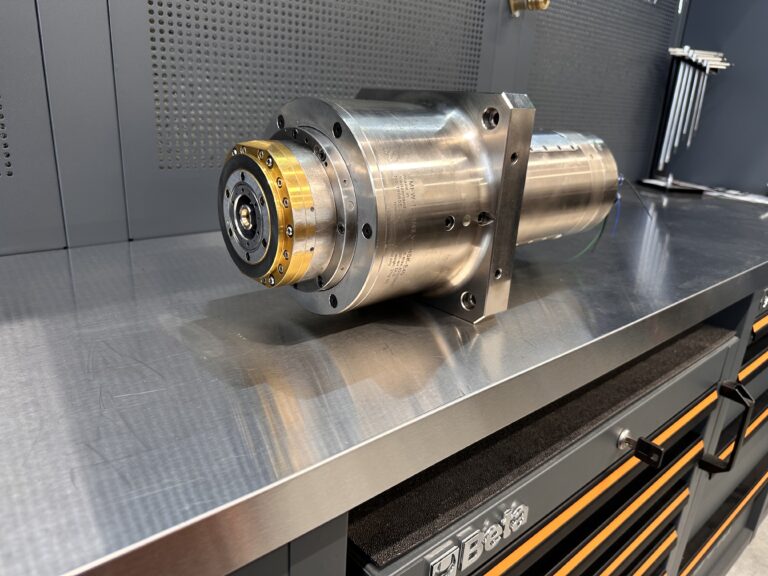

Exactly such an electrospindle arrived at our service – with clear signs of wear, problems with tool clamping and elevated vibration levels. The customer expected not only removal of the failure, but a complete overhaul including removal and reinstallation of the spindle in the machine, so that after service they could rely on stable operation at full speed. We took over the entire process: from on-site diagnostics and removal on the shop floor, through complete electrospindle repair, to installation in the machine, commissioning and cutting tests at the customer’s plant.

For this service we provided a 12-month full service warranty and ongoing technical support.

Electrospindle diagnostics

FISCHER MFW-1224/42 VC HSK-E40

After initial tests on the SPEED HAWK 650 we confirmed typical symptoms of high-speed spindle wear:

- increased vibration at higher speeds,

- reduced surface quality after machining,

- issues with repeatable tool clamping

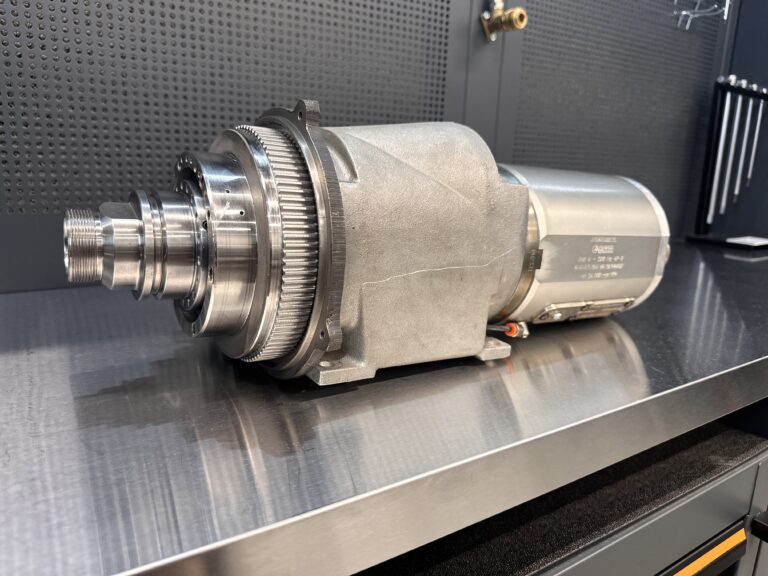

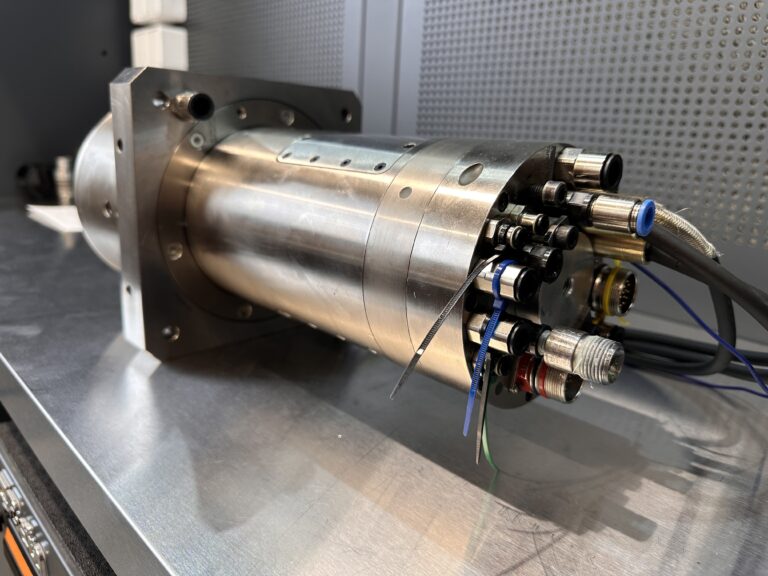

Service process

for FISCHER MFW-1224/42 VC HSK-E40 electrospindle

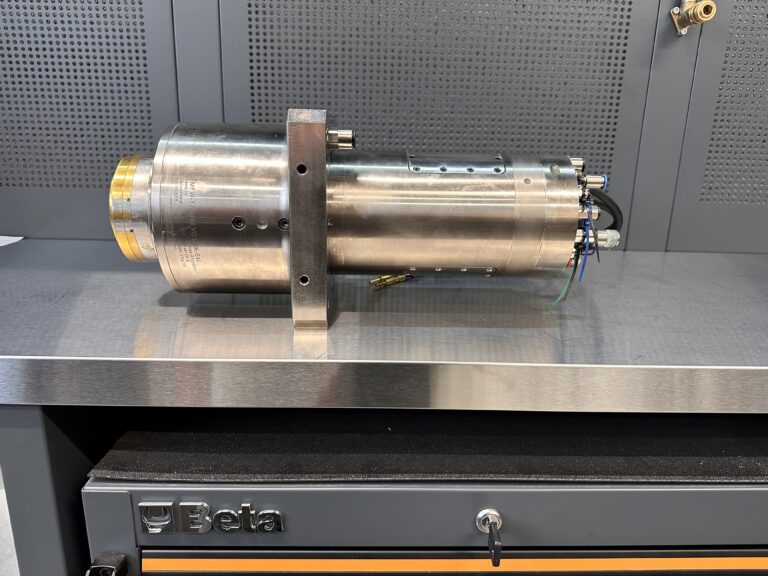

Summary of FISCHER electrospindle repair

MFW-1224/42 VC HSK-E40

- Scope of work: replacement of precision SKF ceramic bearings, new clamping unit, HSK-E40 taper grinding, encoder replacement and complete renewal of approximately 300 internal spindle seals.

- Repair process: removal of the spindle on the customer’s shop floor → full diagnostics and disassembly in our workshop → component replacement and assembly → balancing and test-bench runs → installation in SPEED HAWK 650 and cutting tests.

- Benefits for the customer: lower vibration at high speed, stable machining geometry, extended tool life and increased confidence at 42,000 rpm.

- Reports: the customer received detailed measurement reports for vibration, temperature, clamping force and balancing, along with photo documentation of the key service stages.

- Effect on the machine: consistent surface quality, no more tool clamping issues, smoother machine operation and reduced bearing load.

- Safety and warranty: full as-built documentation and a 12-month comprehensive service warranty on the FISCHER MFW-1224/42 VC HSK-E40 electrospindle.

Frequently asked questions

about FISCHER MFW-1224/42 VC HSK-E40 spindle repair