About us

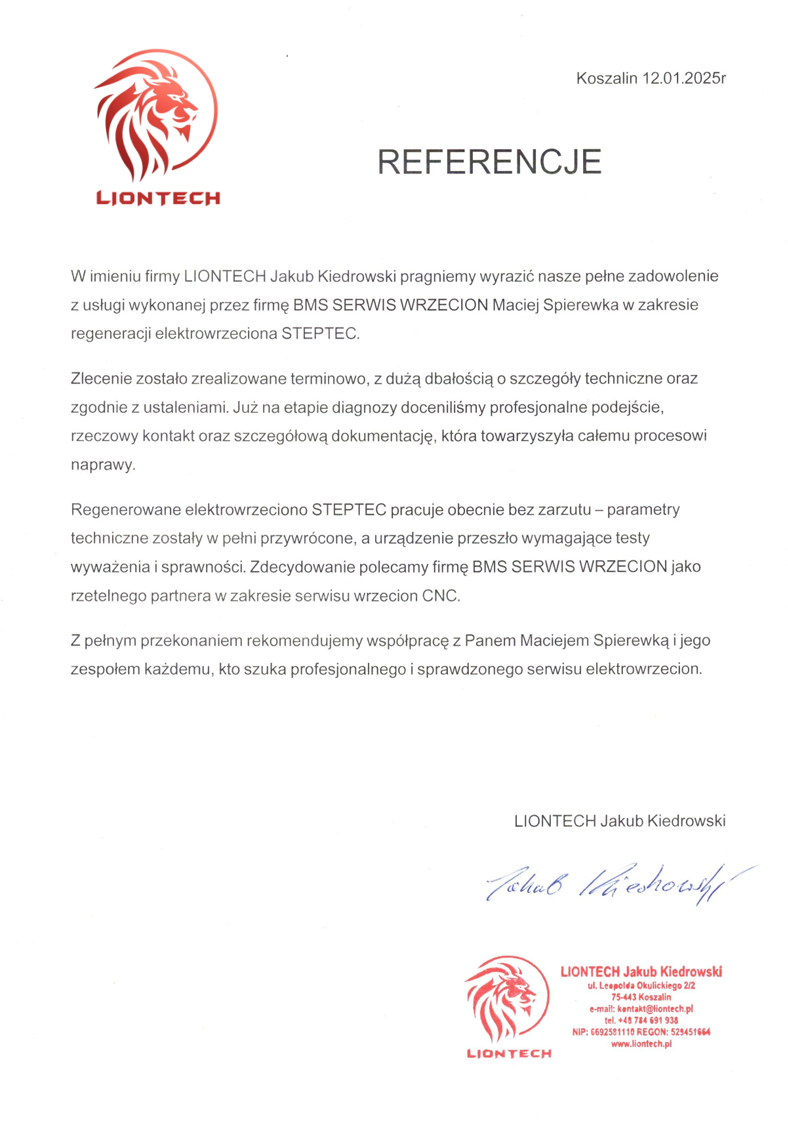

Certificates | References | Technology park

Certificates

and training

Professionalism confirmed by certifications – discover our competencies

In the world of CNC spindle service, there is no room for compromise. Precision, experience, and cutting-edge technological knowledge are the pillars of our work. That’s why we constantly invest in development by participating in specialized training and workshops to ensure the highest level of service for our clients. Discover the certificates that prove our expertise!

Read more

Certificates

and training

Technology

Park

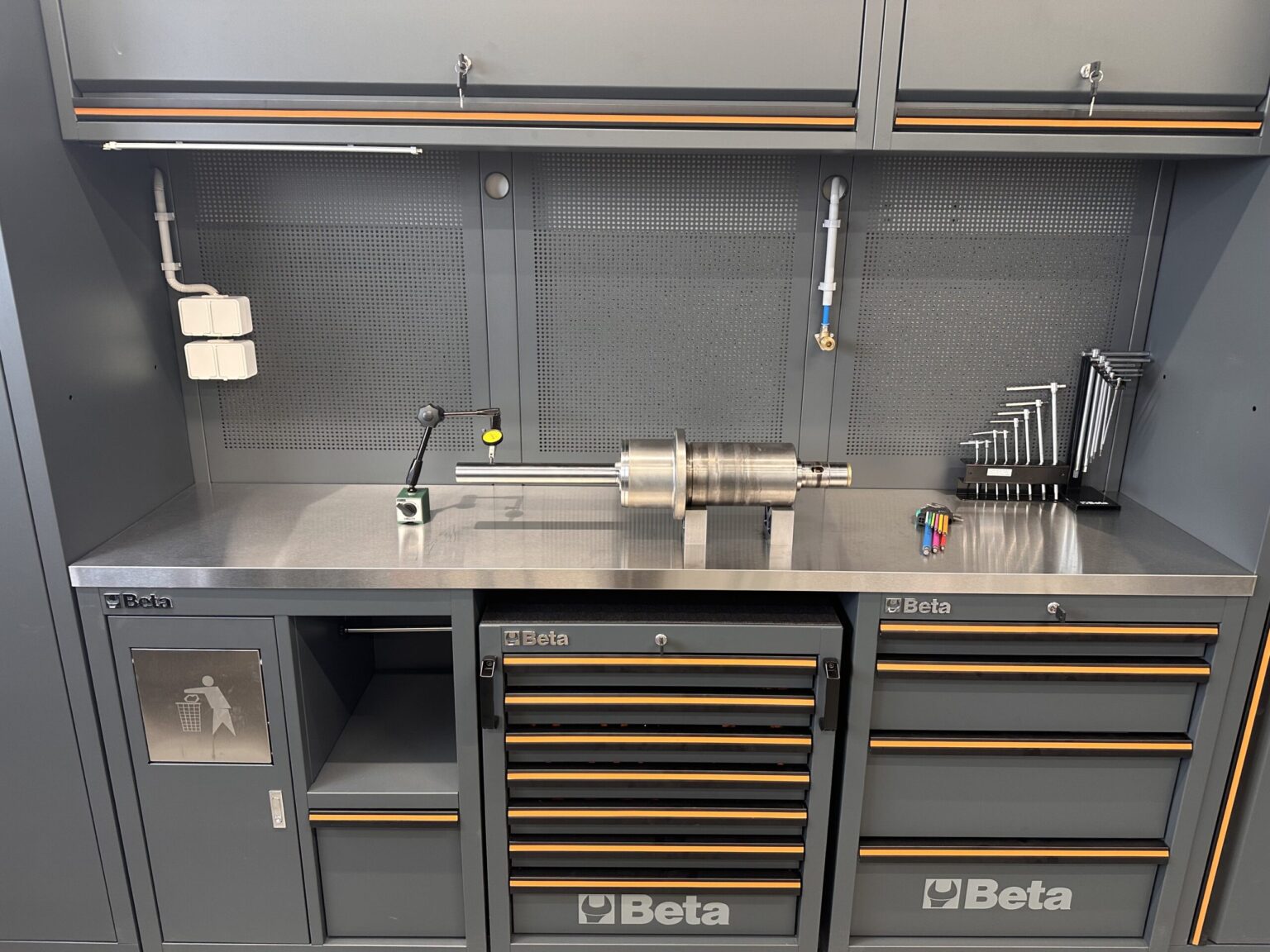

- Cleanroom for assembly of spindles and electrospindles

- Dedicated room for disassembly and cleaning of spindles and electrospindles

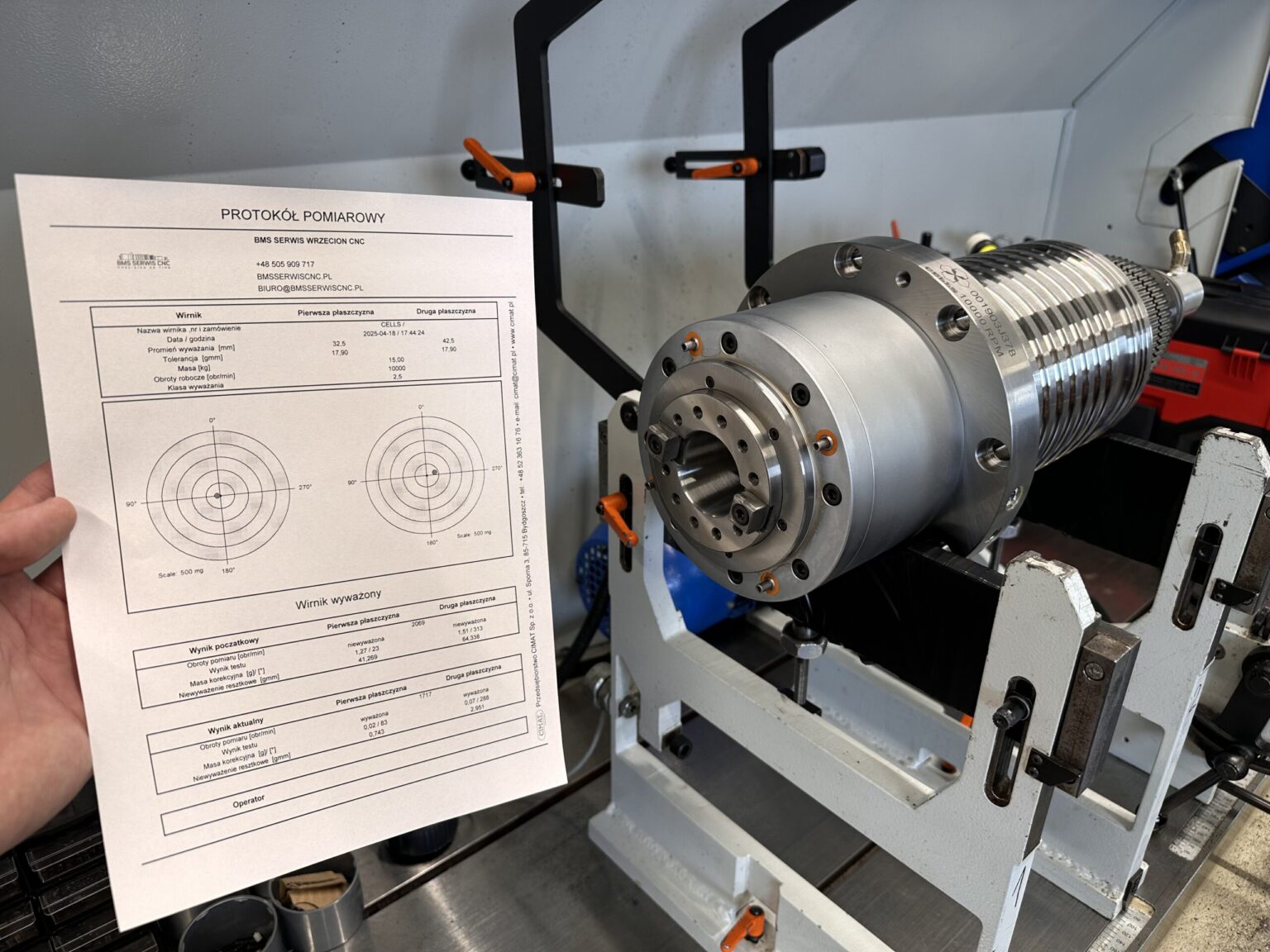

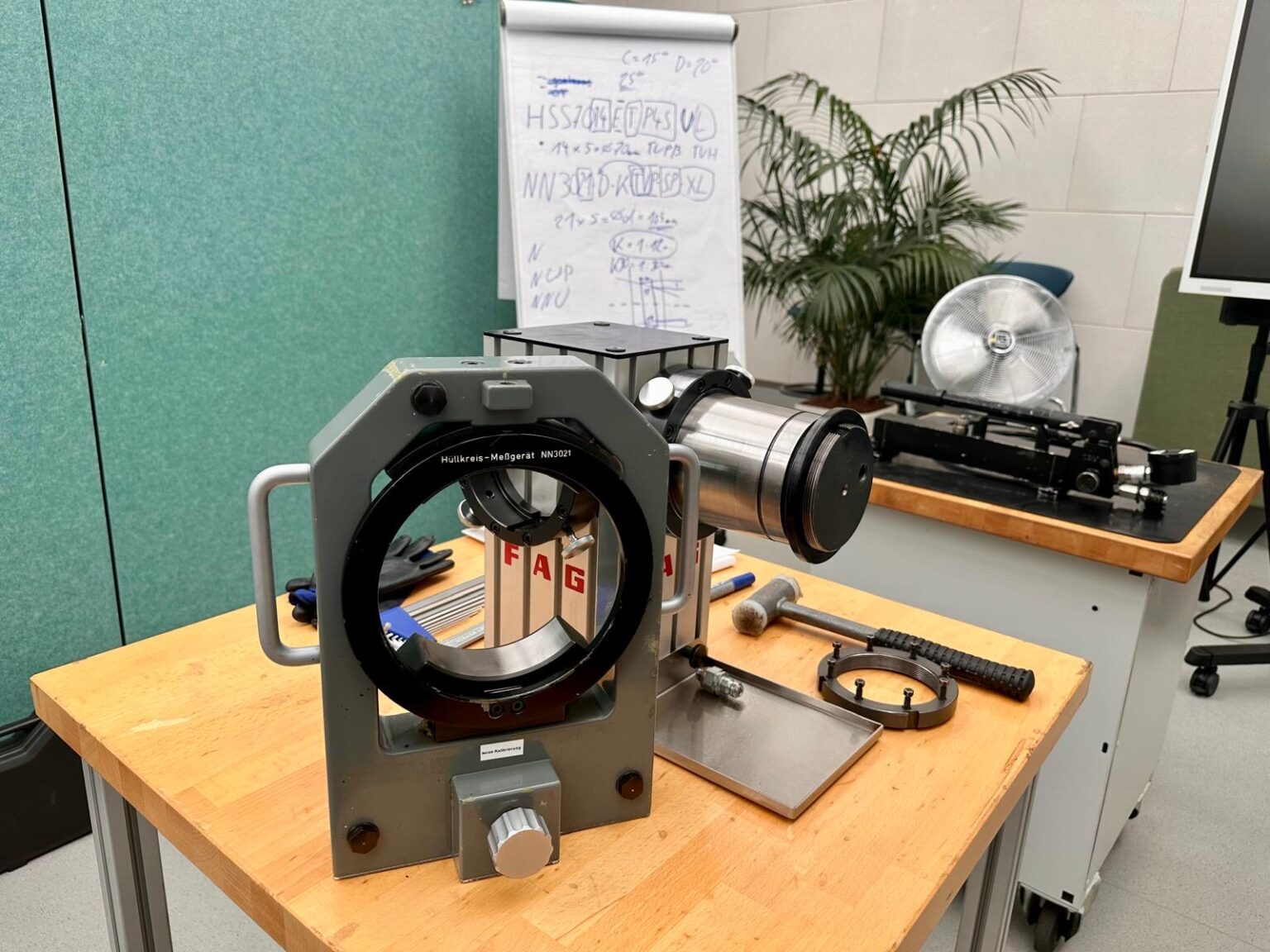

- Diagnostic station for testing performance with printed spindle reports

- CIMAT high-precision balancing machine

- Tool clamping force tester Power-Check 2 for SK, BT, HSK, and Capto tapers

- Encoder and resolver testing kit

- Set for testing diagnostic connectors and sensors on spindles

- Instrumentation for evaluating electrospindle energy efficiency

- Calibration kit for inductive position limit sensors

And many other diagnostic instruments