CHIRON FZ 18 W Spindle Service – Full Warranty

CHIRON FZ 18 W spindle service (SK40) – complete overhaul from removal to installation

-

Spindle manufacturer: CHIRON

-

Machine: CHIRON FZ 18 W

-

Taper: SK40

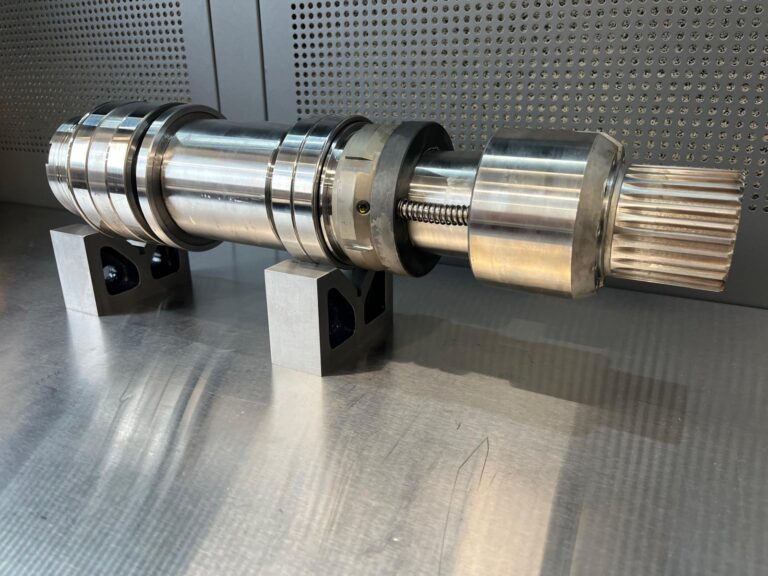

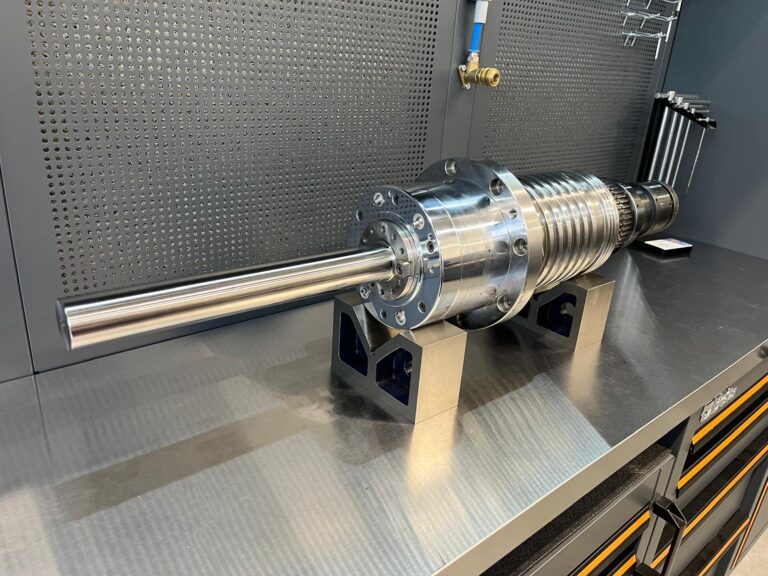

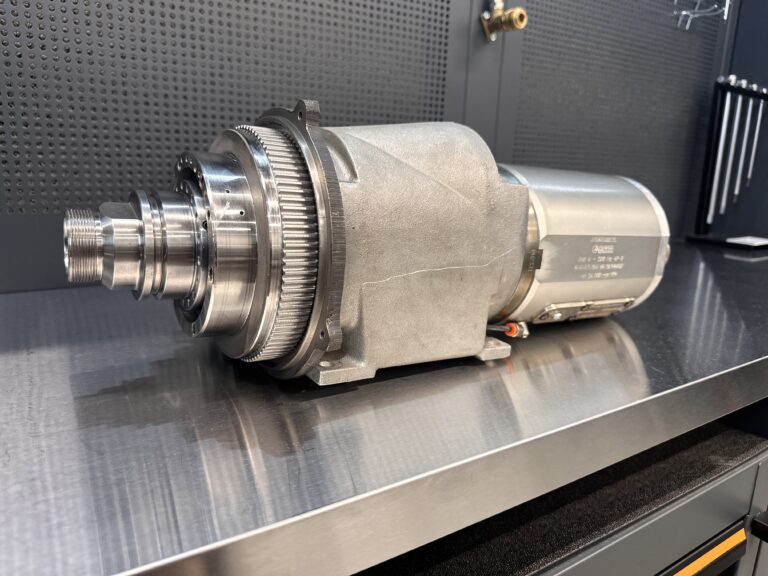

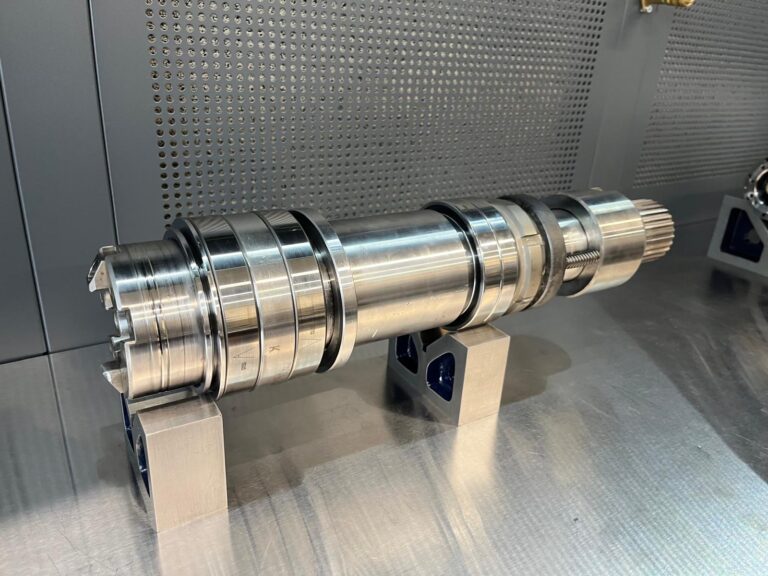

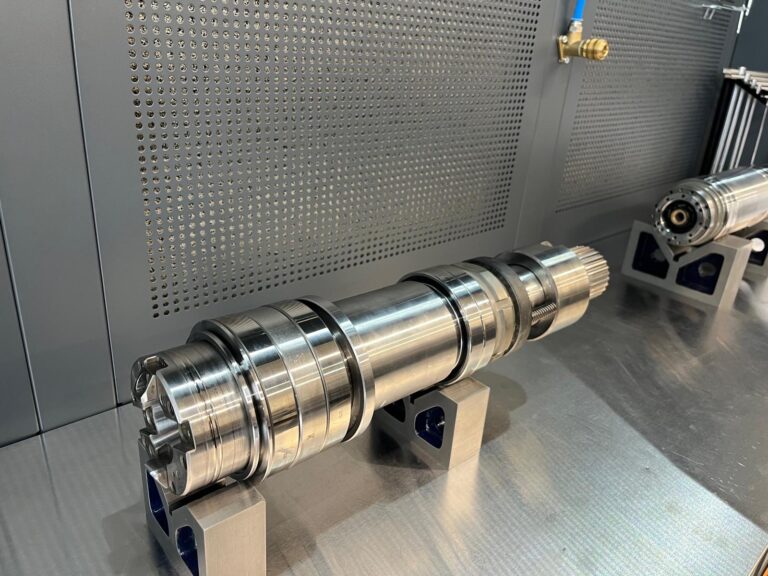

A spindle from the CHIRON FZ 18 W machining center arrived at our service. Two issues were reported: no tool clamping and a worn SK40 taper. This combination typically indicates wear of several components at once: the drawbar mechanism, bearings and the taper itself. We took over the entire process – from removing the spindle from the machine to reinstalling it in line with the CHIRON procedure. Thanks to this the customer has one point of contact, one report and full responsibility on our side.

CHIRON spindle diagnostics

and action plan

After the initial on-machine check we confirmed no clamping and runout on the taper. Together with the client we agreed the scope:

- overhaul and replacement of spindle bearings

- SK40 taper restoration

- drawbar (tool-clamping) restoration for SK40

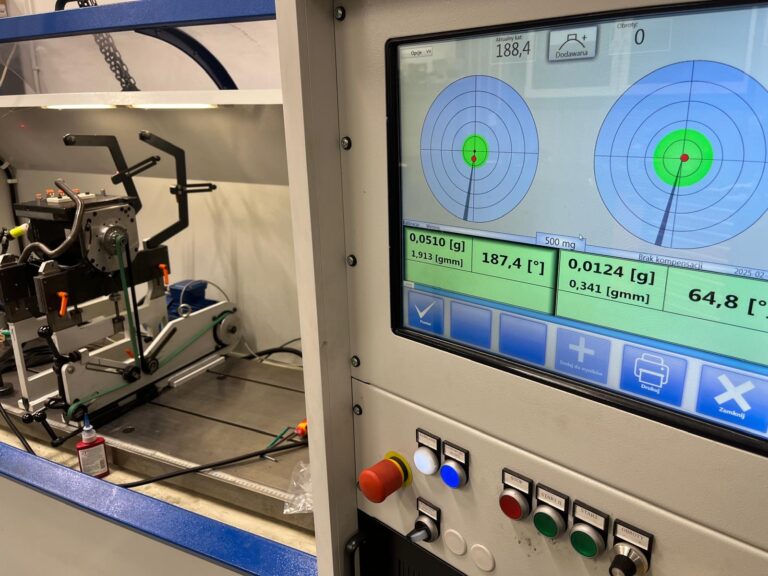

- and precision balancing of the entire assembly.

In addition, we implemented a package of post-installation tests so the customer received a spindle fully ready for production.

Service process

for the CHIRON FZ 18 W spindle

Spindle repair summary

CHIRON FZ 18 W

- Scope of work: bearing replacement, SK40 taper restoration, drawbar restoration, precision balancing.

- Overhaul flow: on-site removal → service at BMS → installation according to CHIRON → tests (warm-up, vibration, temperature).

- Operational benefits: one report and schedule, shorter downtime, predictable lead times.

- Reports: SK40 clamping-force measurement, balancing report, post-installation test results.

- Effect on the machine: stable clamping, repeatable taper geometry, reduced vibration, better surfaces and longer tool life.

- Safety: complete documentation + full warranty and fast technical support from BMS.

Frequently asked questions

about CHIRON FZ 18 W spindle service – SK40 taper

Comprehensive spindle overhaul

CHIRON FZ 18 W

Does your CHIRON spindle need attention? We take full responsibility for the process — from diagnostics and removal, through repair, to reinstallation with measurement reports (including clamping force). Please contact us; we will present the schedule and terms of execution.