Regeneration of the HSD ES 919 electrospindle – full service in 3 days

HSD ES 919 electrospindle service

fast and complete repair at our workshop

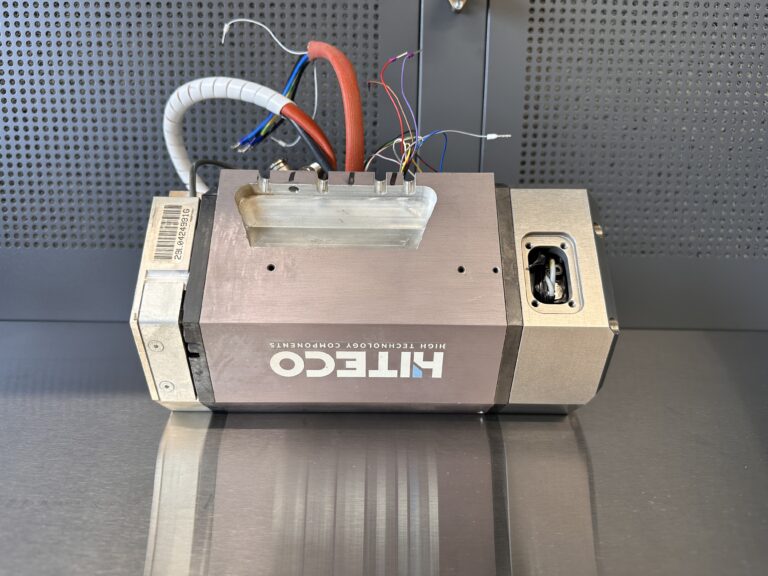

The HSD ES 919 electrospindle was delivered to our service center with urgent need for repair due to bearing system failure and damaged sensors. The entire regeneration process, including disassembly and reassembly at the client’s site, took only 3 days. This fast turnaround was possible thanks to a pre-prepared rotating unit – a solution that minimizes machine downtime.

Electrospindle repair

with rotor and sensor replacement

For the repair, we used a pre-balanced rotor – complete, equipped with a new set of top-class ceramic bearings. Using a ready-to-install rotor significantly reduced repair time and allowed for quick installation, minimizing the customer’s production downtime.

The old rotor was not scrapped – it was disassembled and analyzed in our CNC spindle service workshop. After technical inspection, it was marked and secured as a compatible backup for future HSD ES 919 spindle failures. This way, we maintain our own rotation stock of components, offering even faster service response times.

Additionally, due to damage to the sensor ends, we replaced all HSD inductive sensors with factory-new ones to ensure full compatibility with the machine electronics. This guarantees reliable operation of safety and spindle positioning systems.

Electrospindle repair stages

HSD ES 919

Thanks to these operations, the HSD ES 919 spindle was restored to full working condition and returned to the customer in excellent technical and visual shape.

Professional balancing of HSD ES 919 electrospindle

key to long life

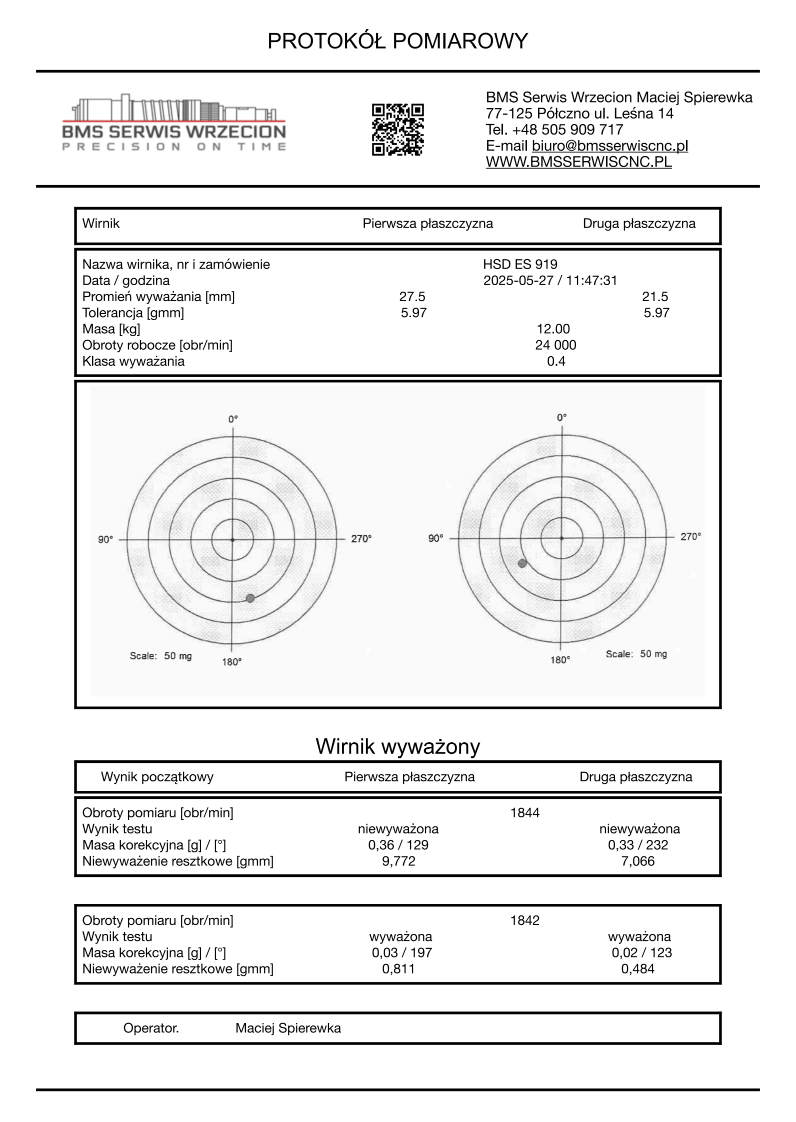

The balancing of the HSD ES 919 electrospindle was carried out at our facility using a dedicated spindle balancing station. We corrected the rotating mass distribution according to the manufacturer’s specifications.

The installed rotor had already been pre-balanced. The final balancing was carried out after full reassembly. We performed vibration and dynamic force measurements across the entire operating range. A full report was issued and provided to the customer.

Final result

successful HSD ES 919 spindle repair

After the repair and testing were completed, the spindle was reinstalled in the client’s machine tool. The machine started up without any issues, and clamping force measurements, concentricity and operation confirmed top quality of service.