Overhaul of damaged GMN TE120sx400-61913 spindle – full service warranty

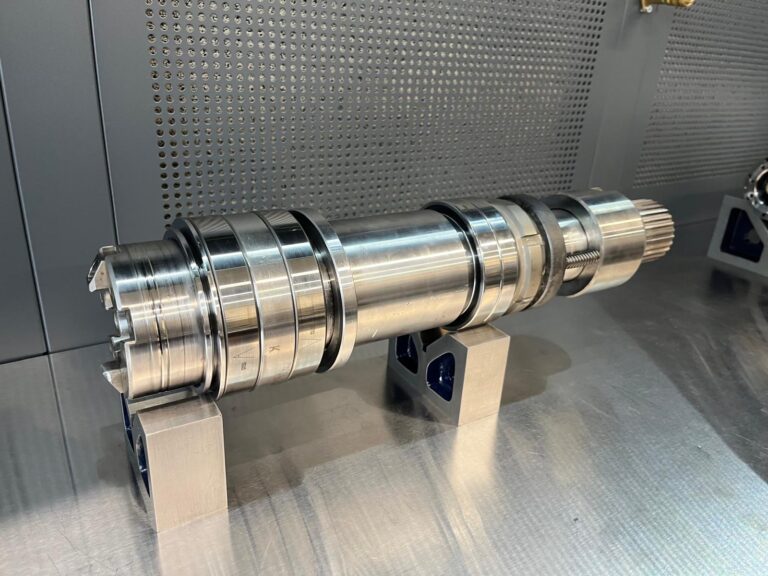

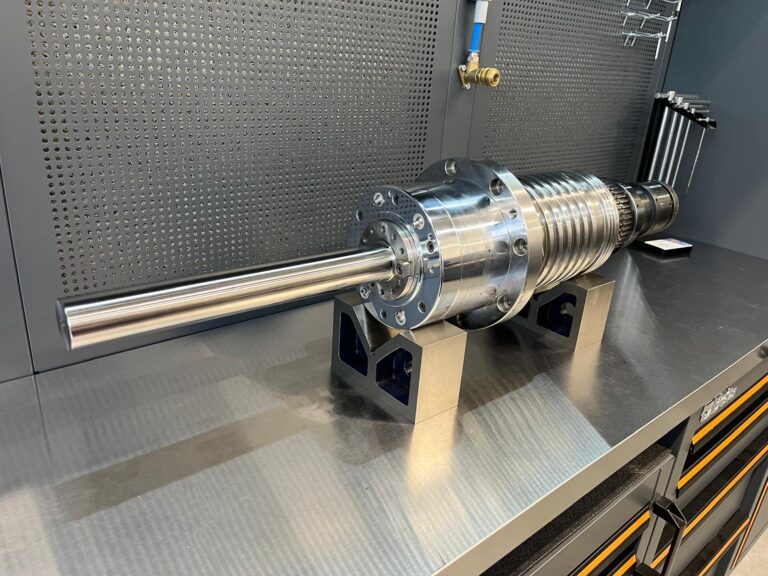

GMN TE120sx400-61913 spindle – restored and reinforced beyond factory standards

-

Spindle model: GMN TE120sx400-61913

-

Tool taper: SK40

-

Rotational speed: 8,000 rpm

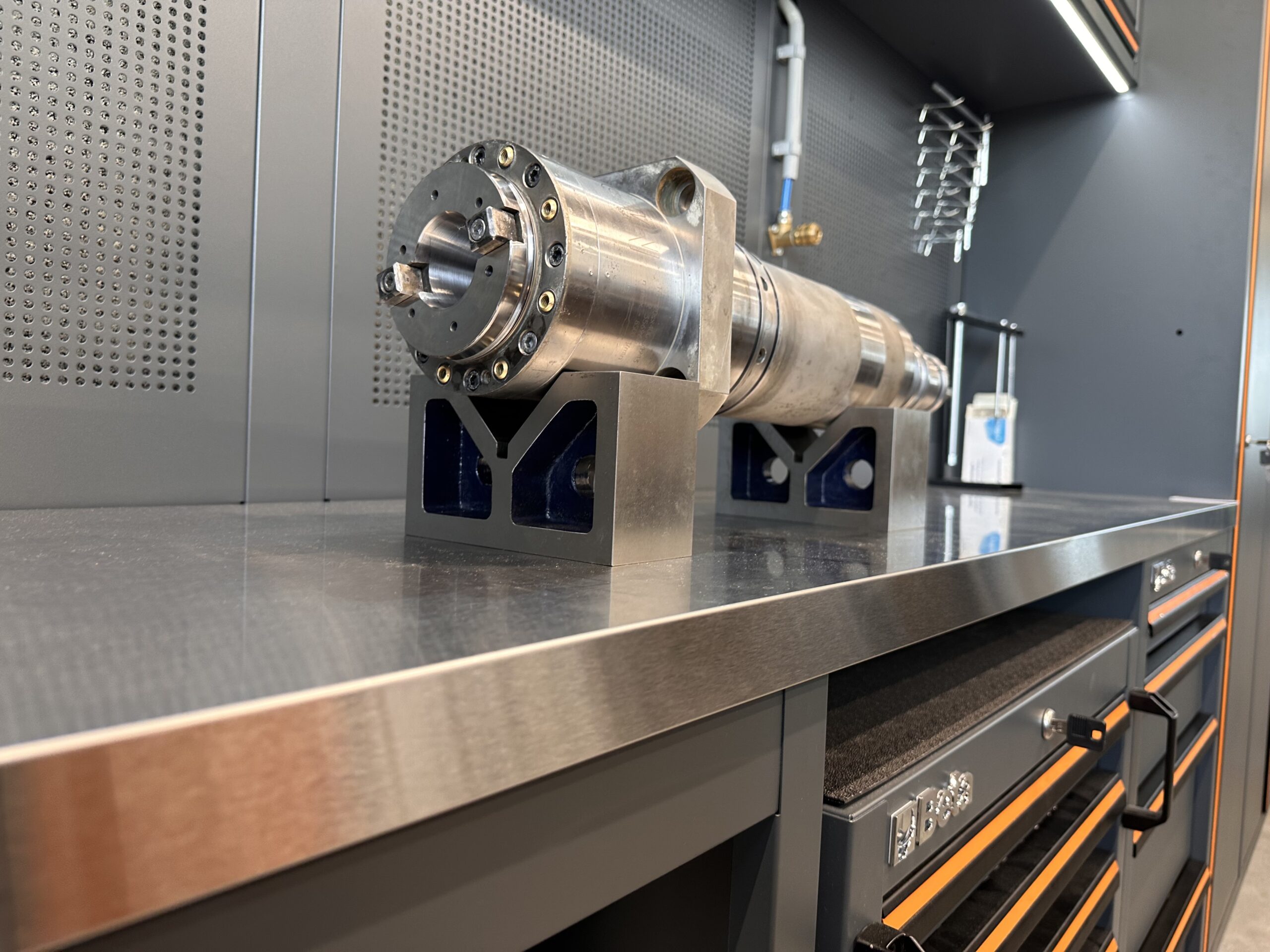

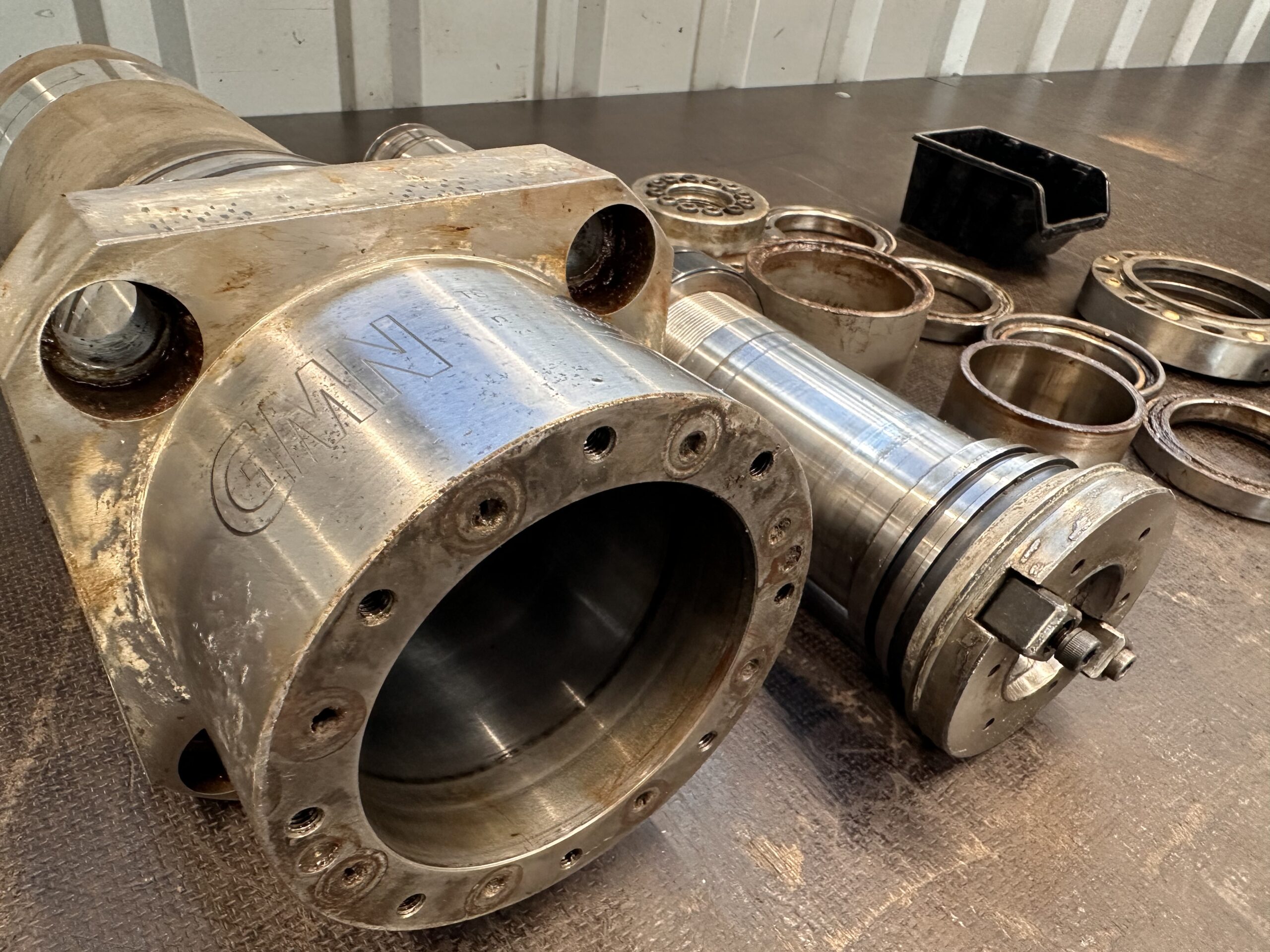

An extremely damaged GMN spindle arrived at our service center, with the SK40 taper severely worn due to prolonged use without prior servicing. The spindle underwent a full overhaul process – from disassembly and diagnostics to component repairs, followed by final testing and dynamic balancing.

Thanks to our experience in electrospindle repairs, we were able to restore the spindle to parameters not only meeting factory standards but even exceeding them in terms of strength and precision.

Scope of work

during the repair of GMN TE120sx400-61913 spindle

Final result

of the GMN TE120sx400-61913 spindle repair

Thanks to the work completed, the spindle was fully restored to operational condition. Moreover, the strength parameters were improved beyond factory levels through the use of more durable components and optimized fits. The spindle is now ready for long-term service with minimal risk of future failure.

For full customer comfort and safety, we provided our additional door-to-door service. On a Saturday, our technician traveled over 1100 km to collect and deliver the spindle in express mode – reducing machine downtime and ensuring guaranteed delivery.

Professional documentation

and warranty after GMN TE120sx400-61913 spindle service

Each step of the repair process was recorded and confirmed with technical documentation. The customer received a complete reconditioning report, measurement results, and a certificate of dynamic balancing. A full service warranty was issued for all performed work.

Also check our spindle disassembly and installation service, performed by our mobile team throughout Poland and across Europe.