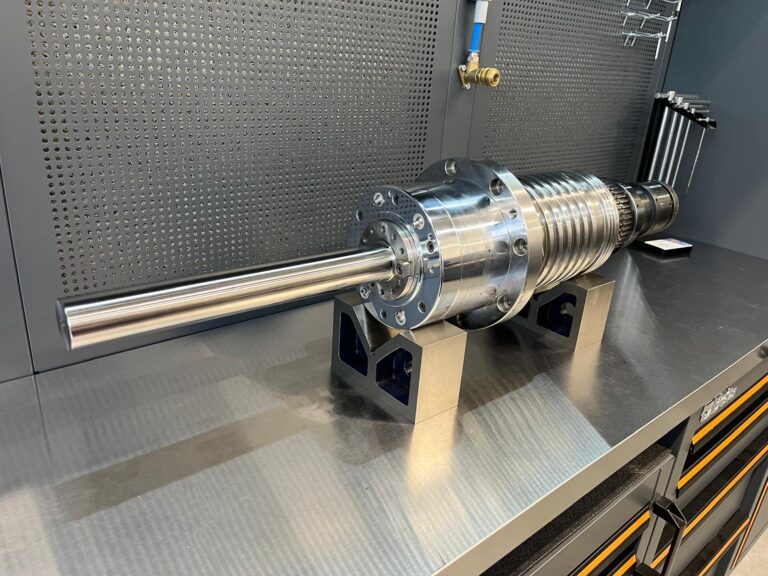

HOMAG BIZ 411 Spindle Repair – HSK 63F Taper

HOMAG spindle repair – BIZ 411 machine

-

Spindle manufacturer: HOMAG

-

Machine: HOMAG BIZ 411

-

Spindle speed: 24,000 rpm

-

Taper: HSK 63F

The scope covered a full HOMAG spindle overhaul from a BIZ 411 machine, rated for 24,000 rpm and using an HSK 63F taper. It included comprehensive diagnostics, replacement of ceramic (hybrid) bearings, precision dynamic balancing, and HSK 63F drawbar rebuild and calibration. The entire process was organized on an expedited basis — delivery and on-site installation the next day after service completion. HOMAG electrospindles are our specialty — we know their construction down to the smallest detail.

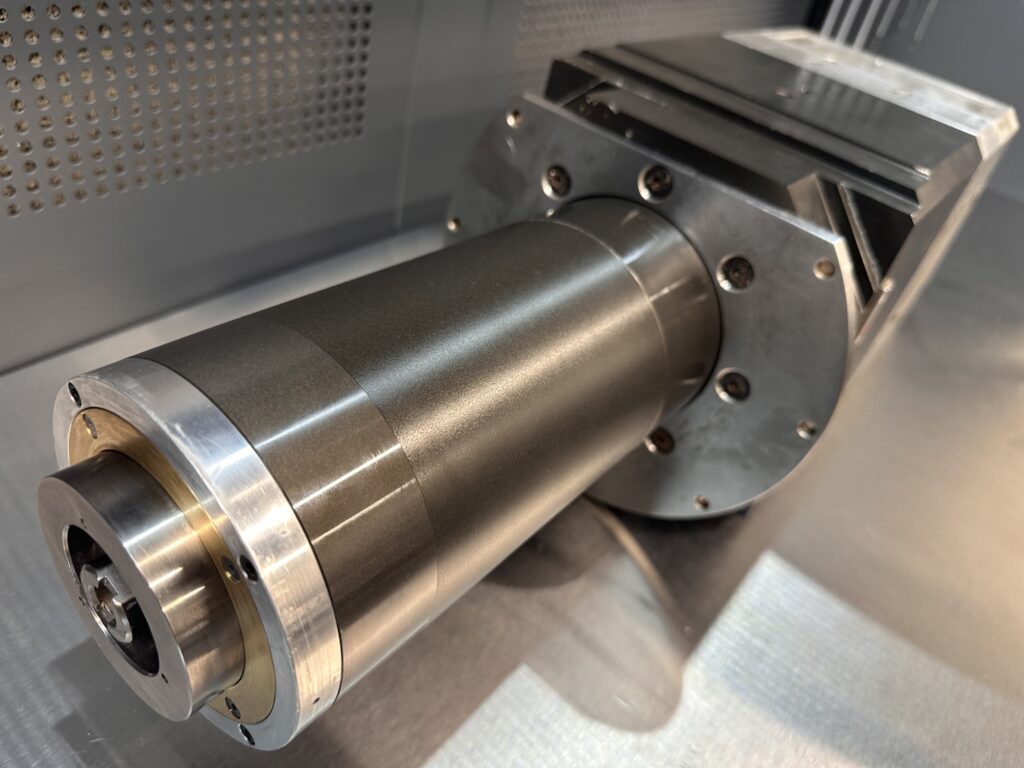

Diagnostics

and condition assessment

The process began with measurements of vibration and temperature, evaluation of radial/axial runout, and verification of HSK 63F taper geometry.

In parallel, we performed:

- tool clamping force measurement

- review of auxiliary systems (seals, air purge, sensors)

Based on these findings, we defined the parts to be replaced and the bearing assembly parameters (class, clearance, preload, lubricant type), which enabled a precise overhaul plan.

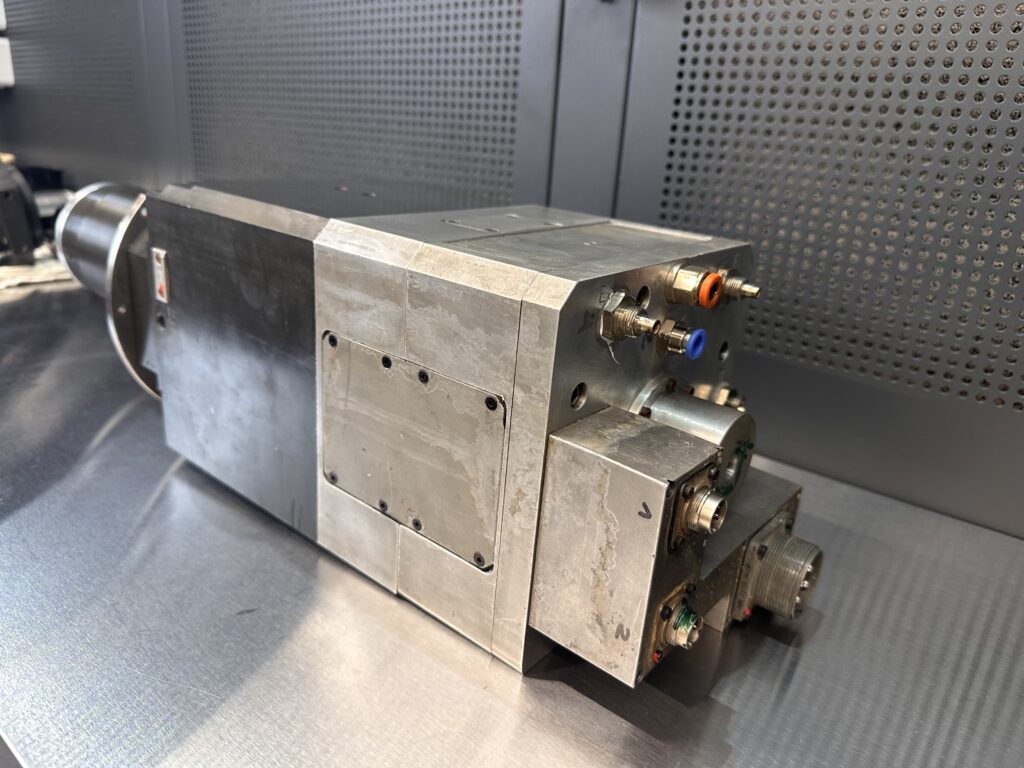

Scope of work

repair of HOMAG BIZ 411 spindle

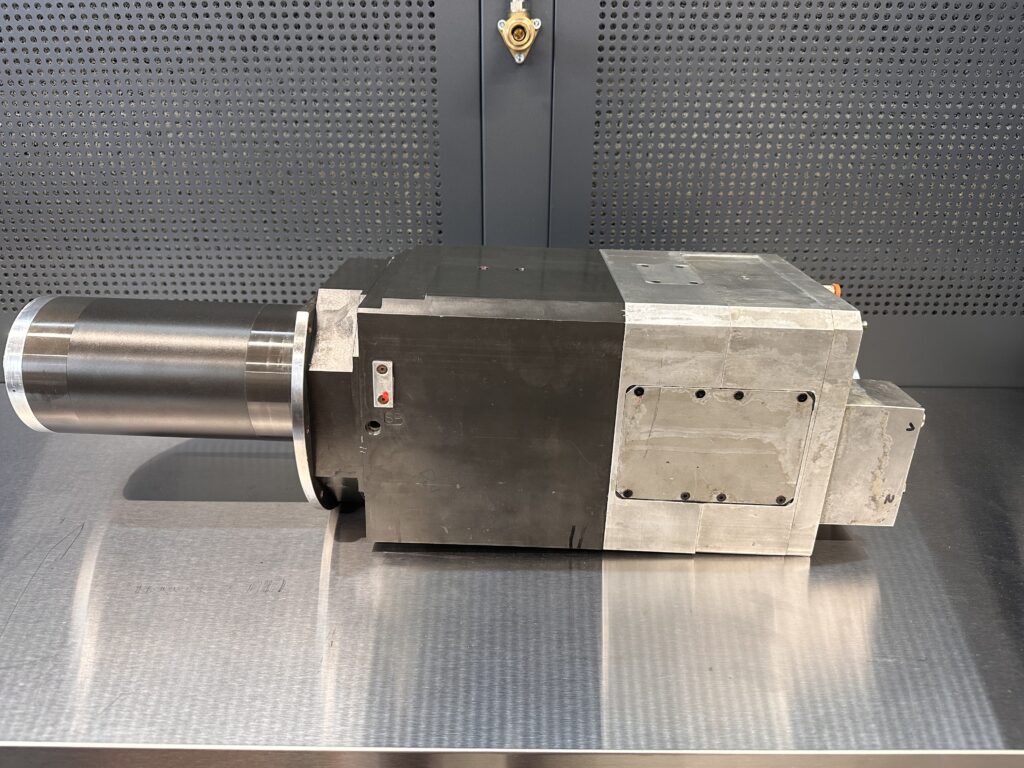

Logistics

delivery & installation

Given the need for rapid production restart, the overhaul was organized in an expedited mode.

The spindle was delivered to the customer’s facility the next day after completion, and installation was carried out by our technician. After installation, we performed commissioning, parameter verification, and test machining passes, confirming speed stability, proper HSK 63F drawbar operation, and low vibration levels.

Results

and benefits

The refurbished HOMAG spindle from the BIZ 411 machine features quiet, stable operation, improved tool-holder geometry, and reduced vibration.

Ceramic bearing replacement combined with precision balancing and drawbar calibration translates into a better surface finish, longer tool life, and greater process repeatability. Fast logistics kept downtime to the necessary minimum.

Specialization – HOMAG

HOMAG spindle overhauls are one of our core areas of activity. Our service team has experience across dozens of HOMAG electrospindle models, which means that every step — from bearing and lubricant selection, through clamping force settings, to precision balancing — follows proven, safe procedures.

In our hands, HOMAG spindle service means a predictable schedule, transparent documentation, and quality that maintains stable operating parameters over the long term.