Express repair of HOMAG SKF electrospindle from Weeke Venture 1M – just 5 days!

Express HOMAG SKF electrospindle service from Weeke Venture 1M – only 5 days from disassembly to reinstallation

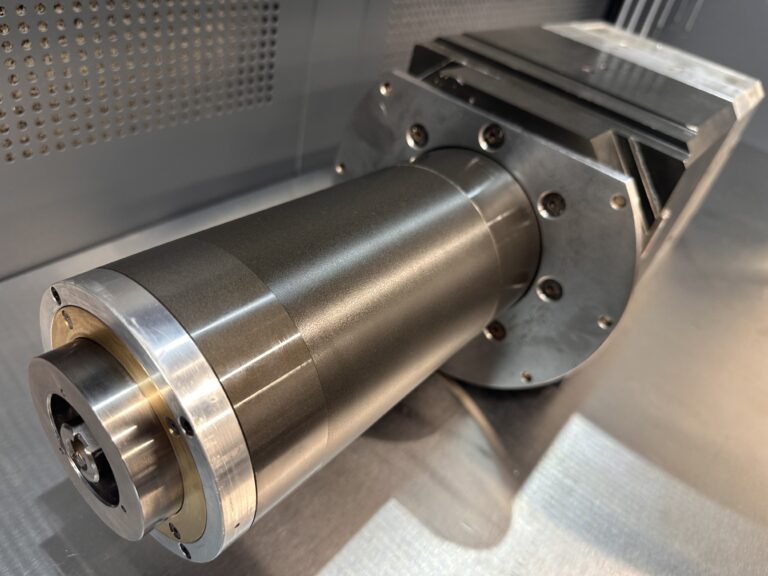

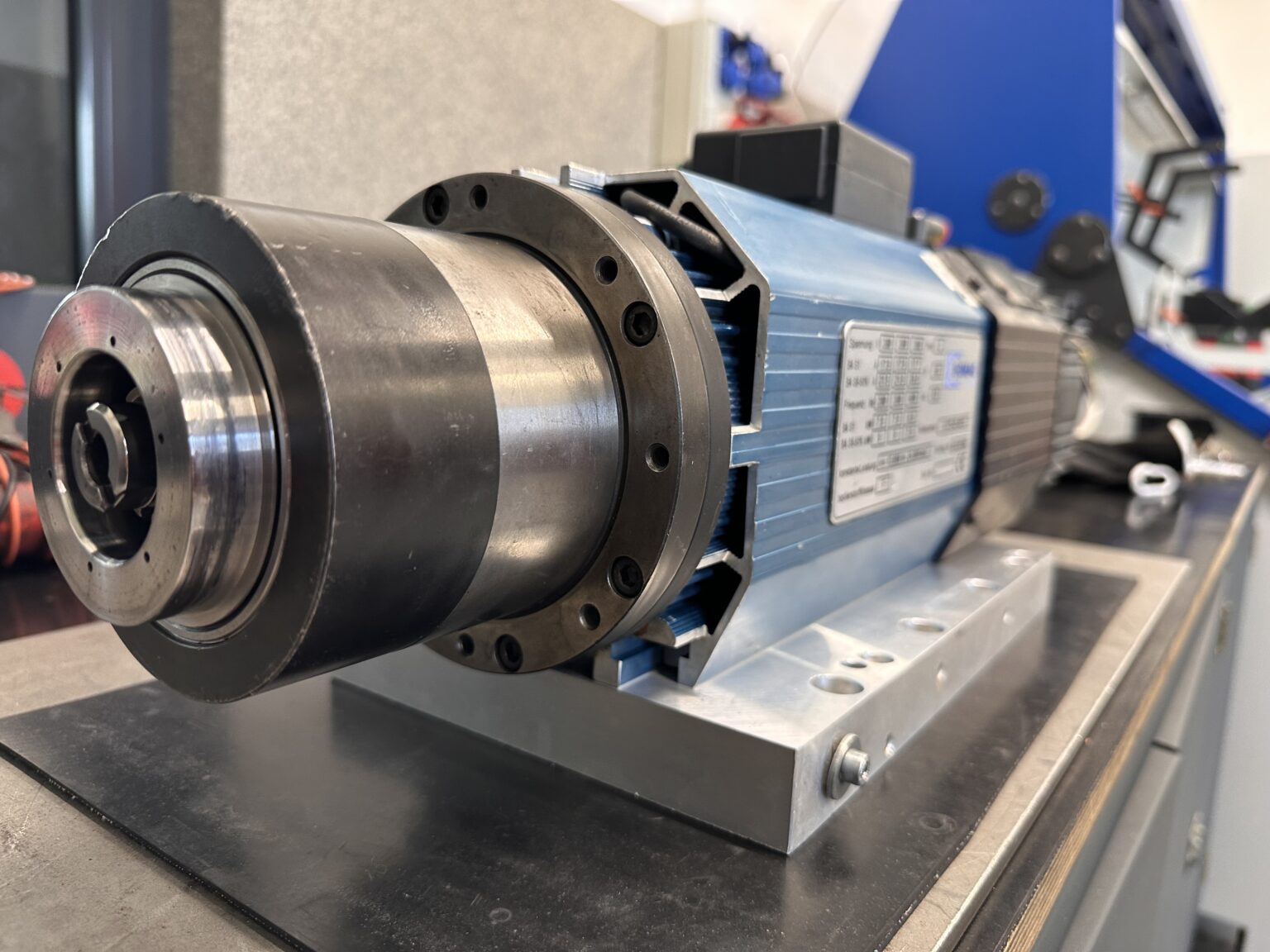

An HOMAG SKF electrospindle, mounted in a Weeke Venture 1M CNC machine used for daily furniture production, arrived at our service center. The customer reported clear signs of spindle degradation: increased noise, noticeable vibrations, and lower machining quality. Due to a tight production schedule and high precision requirements, quick and effective action was essential.

Spindle specifications

-

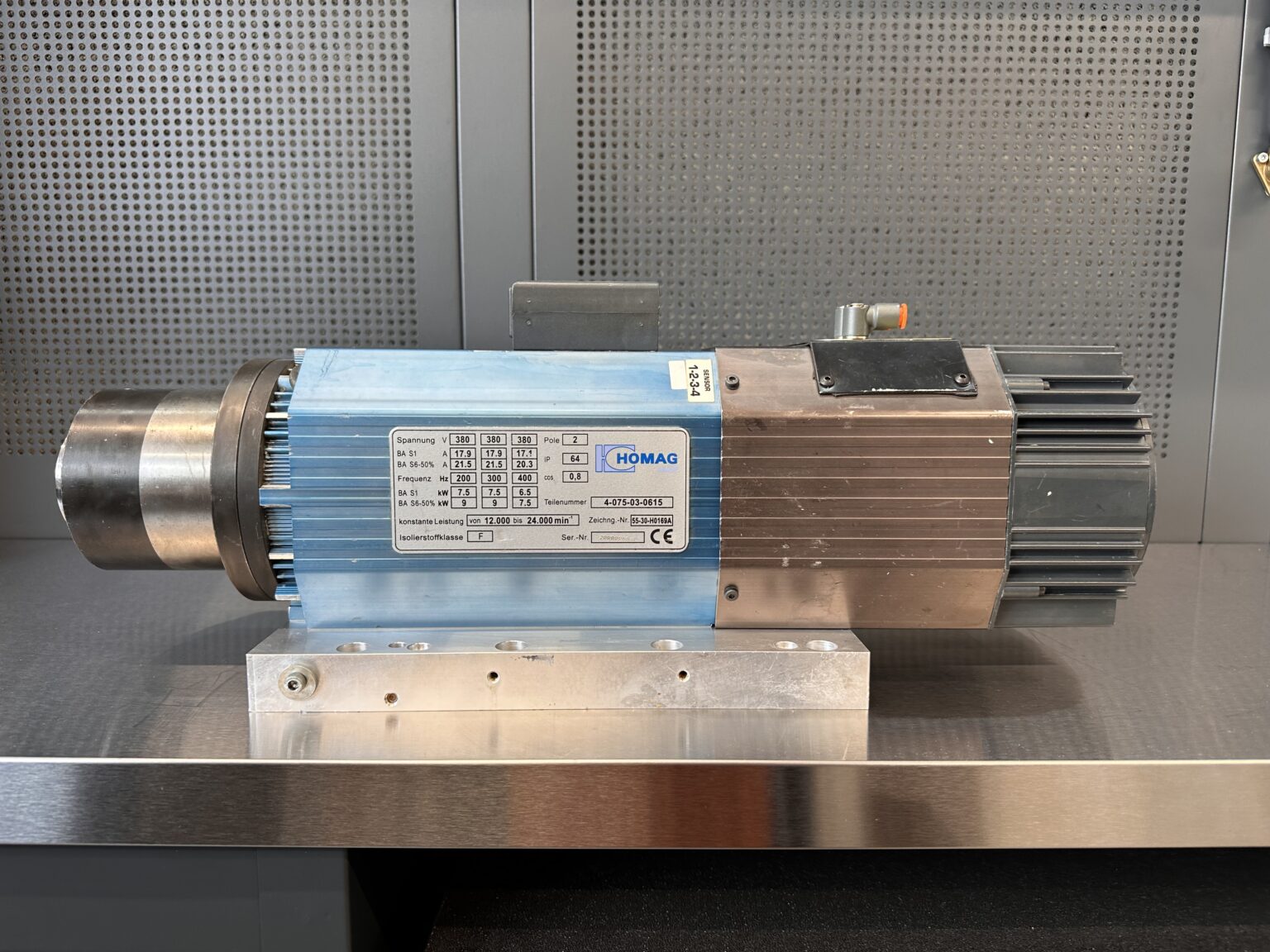

Manufacturer: HOMAG / SKF

-

Model: Homag / SKF 4-075-03-0615

-

Machine: Weeke Venture 1M

Spindle removal from

Weeke Venture 1M and transport

The service began with the removal of the electrospindle on-site by our service technicians, following full safety procedures. Thanks to the team’s experience, this step was completed without the need for external contractors or interruptions to other machines.

Right after disassembly, the spindle was carefully packed in a specialized transport crate and delivered to our facility. For high-class electrospindles like the HOMAG SKF, proper transport is critical — both for the bearings and the precisely calibrated internal components.

Diagnostics and scope

tool taper intact

After delivery to our facility, a detailed diagnosis was performed. The tool taper showed no signs of wear or damage – its geometry was fully within OEM specifications, allowing us to skip restoration. This reduced both repair time and cost for the customer.

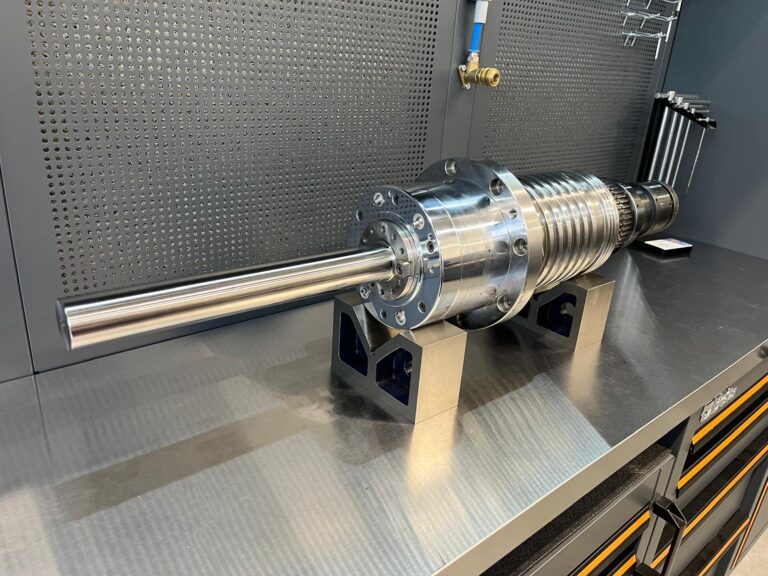

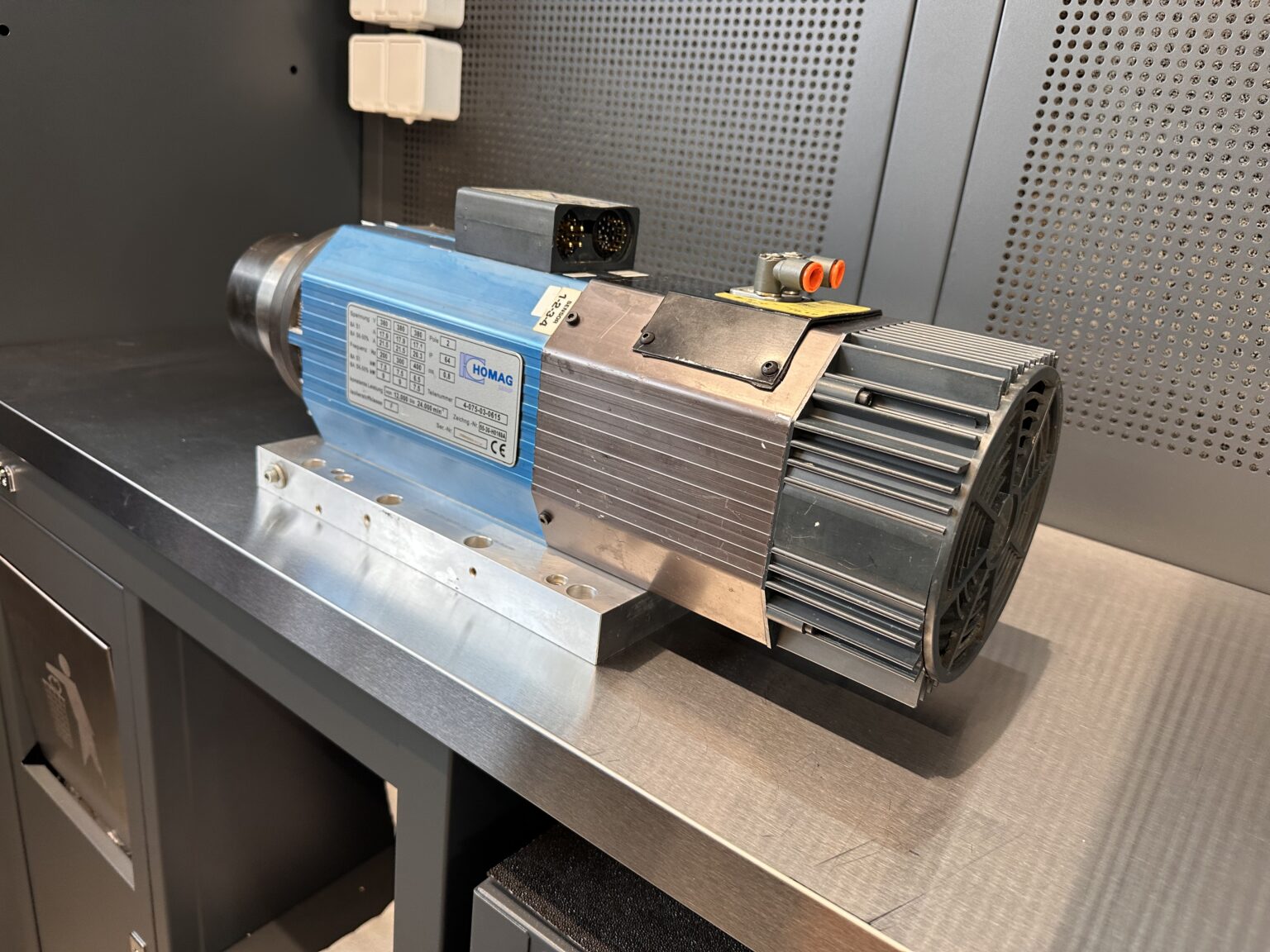

Bearing replacement

restored performance

The main issue was with the worn bearings, which showed signs of scuffing and excessive clearance. We removed the old bearings and prepared the seats for new P4-class precision bearings from a renowned manufacturer – ensuring smooth operation and long service life.

New bearings were installed under controlled conditions – with precise temperature and cleanliness. We also checked preload clearance and applied lubrication per the manufacturer's technical documentation.

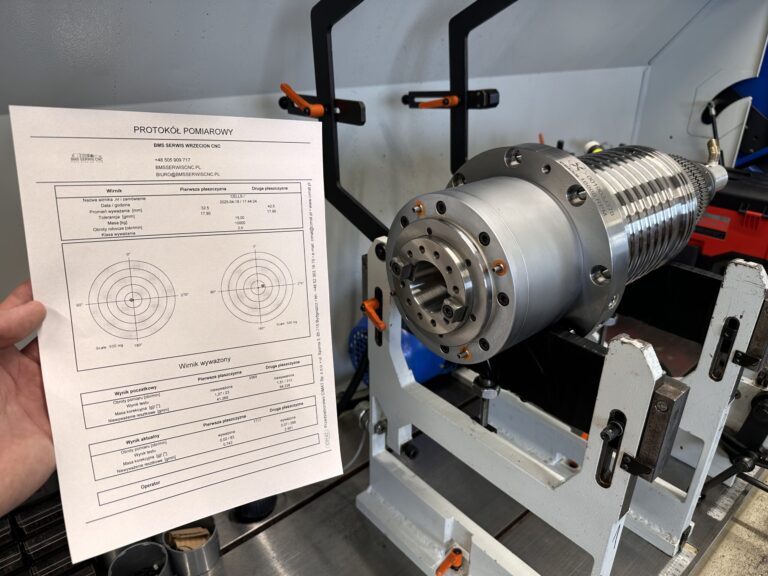

Dynamic balancing

0.4G accuracy class

After rotor assembly, the spindle was transferred to our dynamic balancing station, where we achieved 0.4G class accuracy using a high-precision balancer. This level is reserved for top-tier units and exceeds the standards of most industrial service providers.

The effects were immediate – quiet spindle operation, no noticeable vibrations, and reduced bearing loads, ensuring extended service life.

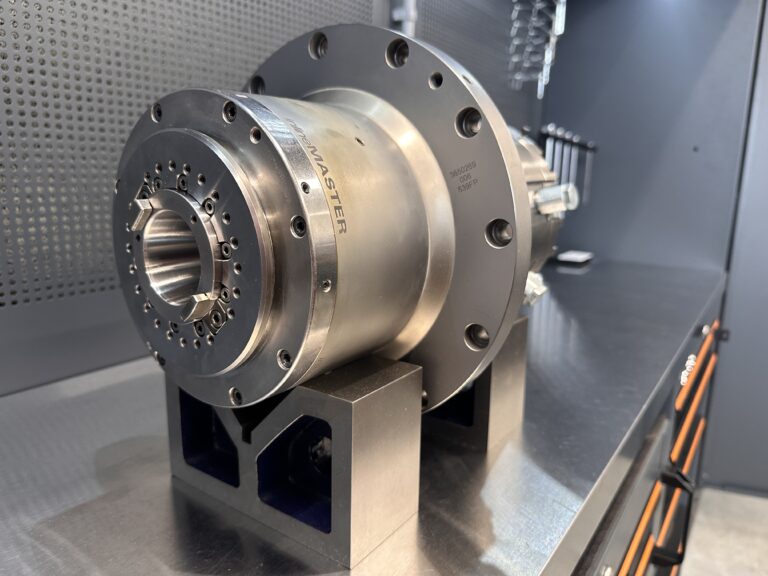

Testing, running-in

and calibration

Before final installation, the spindle went through several hours of running-in, followed by load tests and final calibration. We checked concentricity, tool clamping force, spindle alignment, and thermal stability under prolonged operation.

Installation and commissioning

spindle ready for operation

The last step was transporting the electrospindle back to the customer and its reinstallation in the CNC machine. All tasks were completed by our team, providing a full door-to-door service without needing third-party support.

The entire operation – from removal, transport, repair, to reinstallation – took only 5 business days, which is an excellent result considering the scope and precision required.