Professionalism confirmed by certifications – discover our competencies

In the world of CNC spindle service, there is no room for compromise. Precision, experience, and the latest technological know-how are the foundation of our work. That’s why we continuously invest in development, participating in specialist training and workshops to ensure the highest service quality for our clients. Discover our certificates that confirm our competence!

Certificate of training completion

Synergy MTO – NTN-SNR

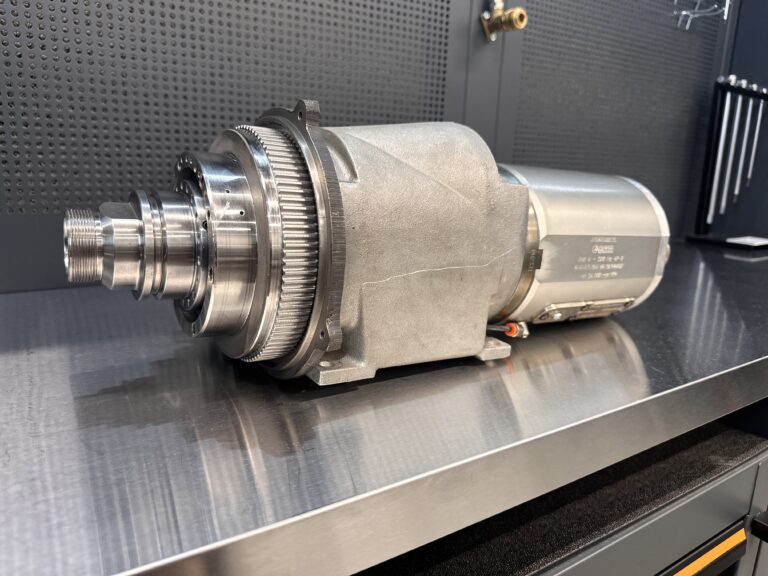

The training conducted by NTN-SNR was aimed not only at presenting advanced theoretical knowledge in the field of bearing distribution and technology, but above all at practical preparation for spindle repair processes. Importantly, it was a specialized service training organized in France, where a dedicated NTN-SNR service technician intensively trained us in precise spindle repair techniques.

Certificate

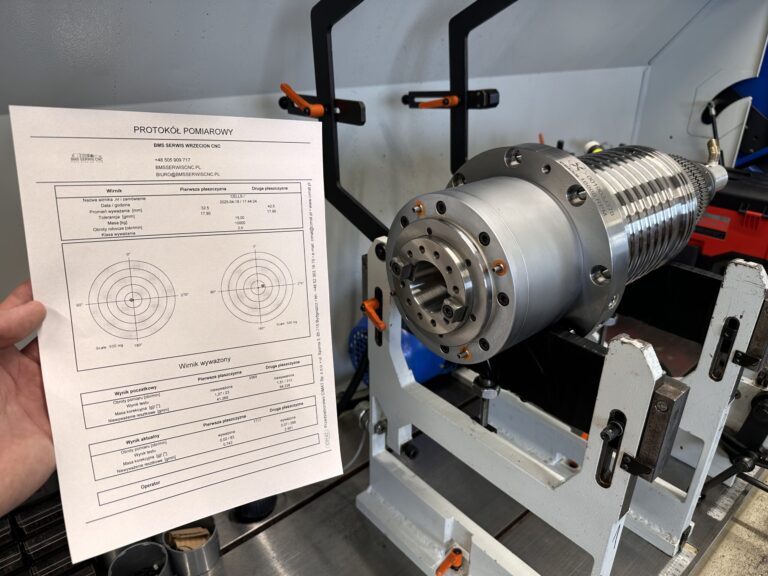

Schaeffler Technology Center – training

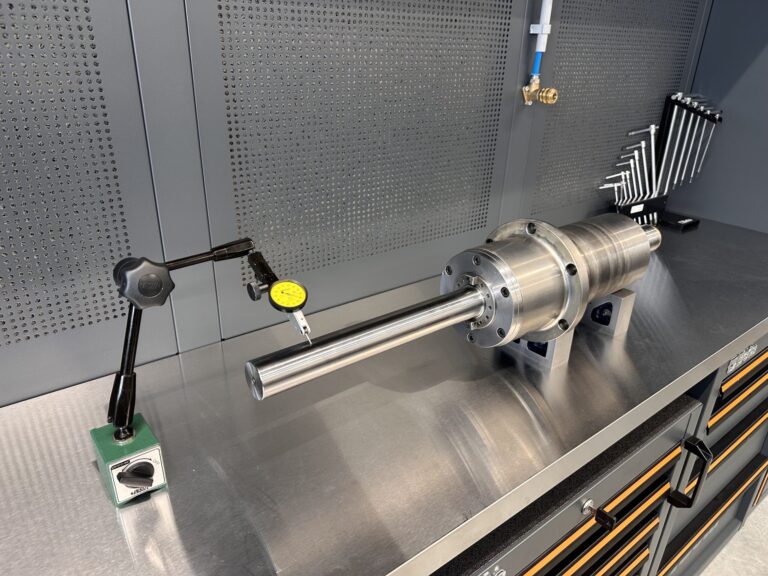

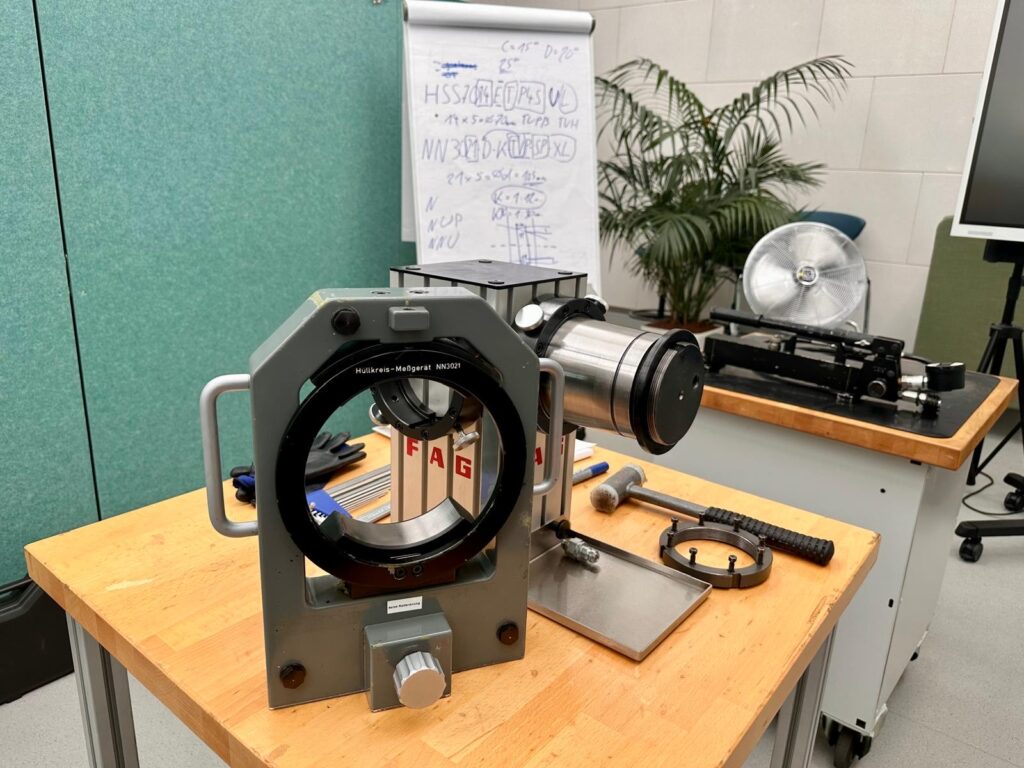

A specialist training organized in Germany at the FAG plant – one of the key brands of the Schaeffler Group. The training included both an intensive theoretical part and an extensive practical module. Under the supervision of experienced technicians, we improved our skills in assembling precision spindle bearings using specialized measurement devices and tools. Hands-on exercises with real-life examples enabled us to master the safe and precise bearing installation process.

Certificate of participation in workshops

"Precision components used in machine tools" – MARGO

The training covered a broad range of topics related to:

- High-precision linear positioning techniques,

- Super precision bearings (NSK, FAG),

- Safe machine operation (HSE in maintenance),

- Assembly and maintenance of bearing systems and belt drives.

Why precision training

is key in spindle servicing

Servicing CNC spindles is one of the most demanding areas in machine maintenance. Each spindle is a precisely operating mechanism where even the slightest deviation can lead to serious failures or loss of machining quality.

Precision training enables us to:

- Apply the latest spindle assembly and disassembly techniques,

- Work within micron-level tolerances,

- Detect subtle symptoms of component wear,

- Conduct full mechanical and electrical diagnostics,

- Implement the latest technological solutions directly at client facilities.

Thanks to knowledge gained in certified training, we can ensure:

- Extended spindle lifespan after repair,

- Shorter lead times for service,

- Full operational safety of machines serviced by us.

Podsumowanie

Our certificates confirm real skills – we continuously expand our knowledge to ensure your machines operate reliably and with full precision. By choosing our service, you choose reliability and the highest service quality.