Royal spindle repair on MTcut V85

Complete repair of the ROYAL spindle from the MTcut V85 machine

-

Spindle: ROYAL

-

Machine: MTcut V85

-

Spindle speed: 12,000 rpm

-

Taper: SK40

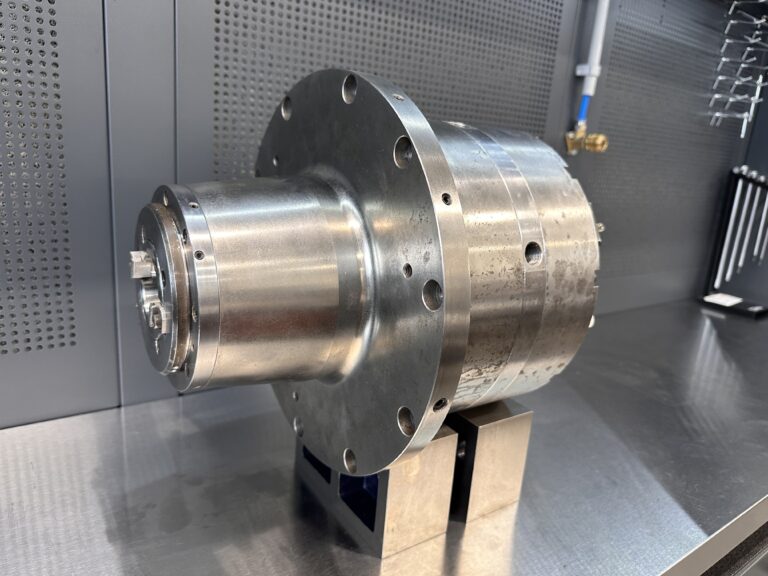

A ROYAL spindle working in a MTcut V85 machining center arrived at our service. The unit with a speed of 12,000 rpm and SK40 taper failed due to bearing seizure. The spindle was immediately removed by the client’s Maintenance Department, and the entire process was supervised and instructed by BMS Spindle Service specialists.

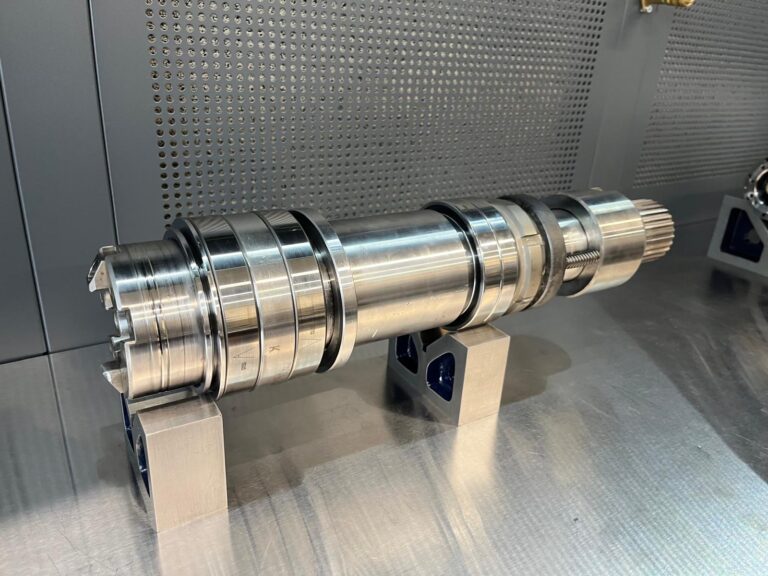

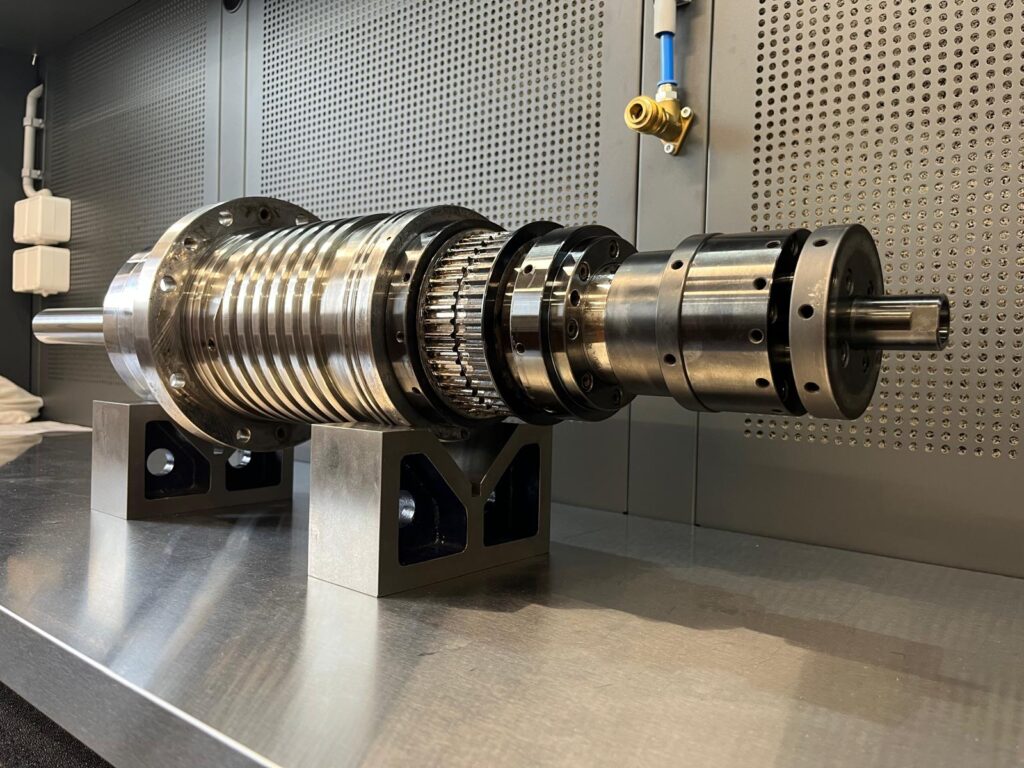

During diagnostics we confirmed heavy wear of rolling elements and damage to the thrust surfaces in the bearing seats. A decision was made to perform a complete spindle repair.

ROYAL spindle repair step by step

ROYAL spindle repair – MTcut V85

Project summary

key findings and results

- Cause and decision: stoppage due to bearing seizure; decision to perform a full repair.

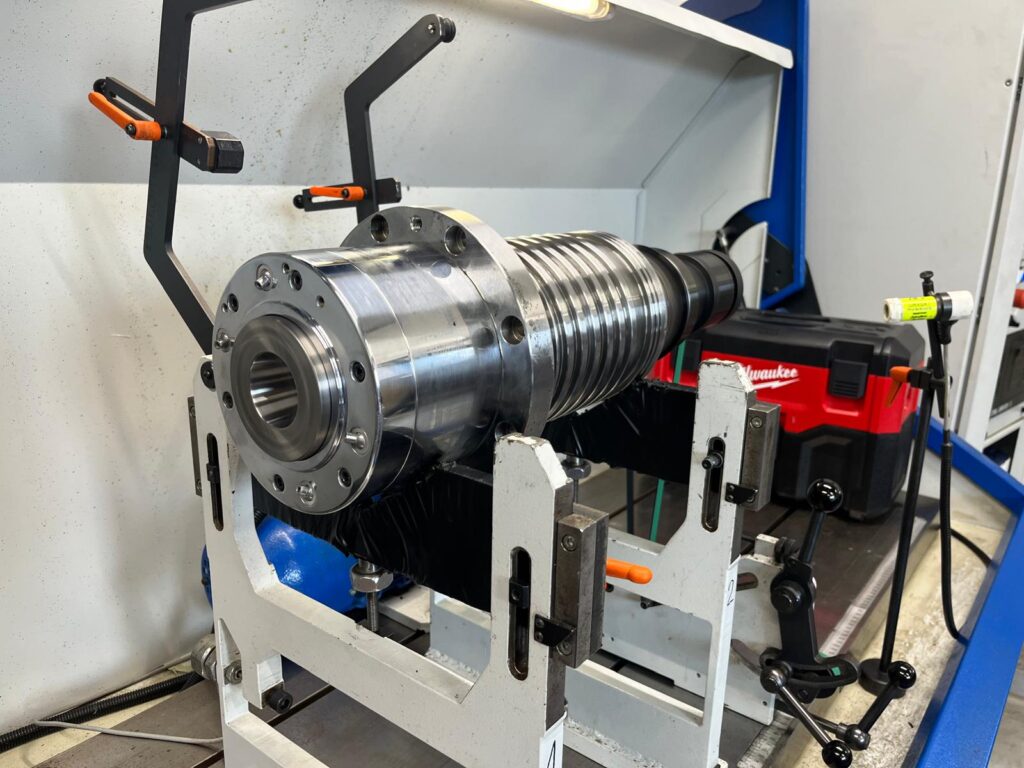

- Removal/Installation under supervision: work carried out by the client’s Maintenance Department with BMS phone guidance (sequence, torques, safety).

- Internal service scope: complete disassembly and cleaning, replacement of the entire bearing set with full-ceramic, SK40 taper restoration, and tool clamping force calibration.

- Assembly and verification: assembly under controlled conditions, full-speed testing, runout and temperature measurements — results within tolerance; support for the first start-up on MTcut V85.

- Result and recommendations: parameters restored (up to 12,000 rpm), stable operation and production readiness; delivered maintenance guidelines and documentation (clamping force checks, periodic taper inspection, clean tool seat).

Frequently asked questions

ROYAL spindle repair / MTcut V85

Need ROYAL spindle repair?

Contact us

Do you need ROYAL spindle repair (MTcut V85, SK40, 12,000 rpm) — with full-ceramic bearings, taper restoration and clamping force calibration? BMS Spindle Service will guide you through safe removal and installation and restore the spindle to full working order.