Chiron Spindle Repair and Service

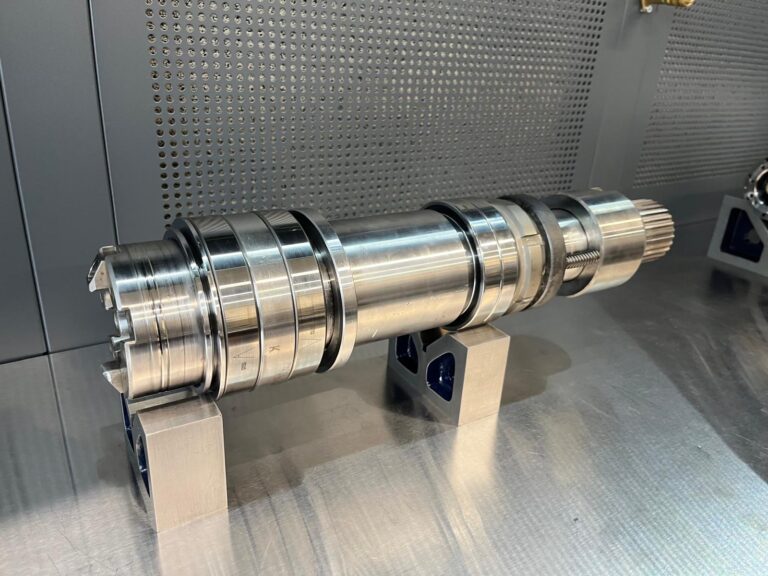

We specialize in the professional regeneration and repair of Chiron spindles used in CNC machining centers. We offer a full range of services — from diagnostics, mechanical and electrical repairs, to final testing and dynamic balancing.

Chiron

Spindles

Chiron is one of the leading manufacturers of CNC machining centers. Spindles from this brand are known for their high precision and performance, but due to usage, they require regeneration: from bearing replacement, sensor repairs, to coil rewinding.

With our services, we restore the factory parameters of Chiron spindles and ensure their reliability for years to come.

Case studies

repair of Chiron spindles

CHIRON FZ 18 W Spindle Service – Full Warranty

A spindle from the CHIRON FZ 18 W machining center arrived at our service. Two issues were...

Read more

CHIRON HSK 63A spindles repair – CNC service and balancing

Two spindles from the renowned CHIRON brand, operating in machines from the same manufactu...

Read moreProfessional Chiron Spindle Service

Step by Step

The Chiron spindle service process is multi-step and includes both mechanical and electrical repairs:

Spindle Dismantling and Reassembly

Technical Diagnostics

Coil Rewinding

Spindle Taper Regeneration

Cooling System Repair

Bearing and Seal Replacement

Dynamic Balancing

Final Testing

We service Chiron spindles used in vertical, horizontal, and 5-axis machining centers. We guarantee compliance with the manufacturer’s technical documentation.

Need a Chiron

Spindle Repair?

We offer free quotes and fast turnaround times. We serve clients across Poland and Europe.

Contact us — we’ll respond today!

CONTACT