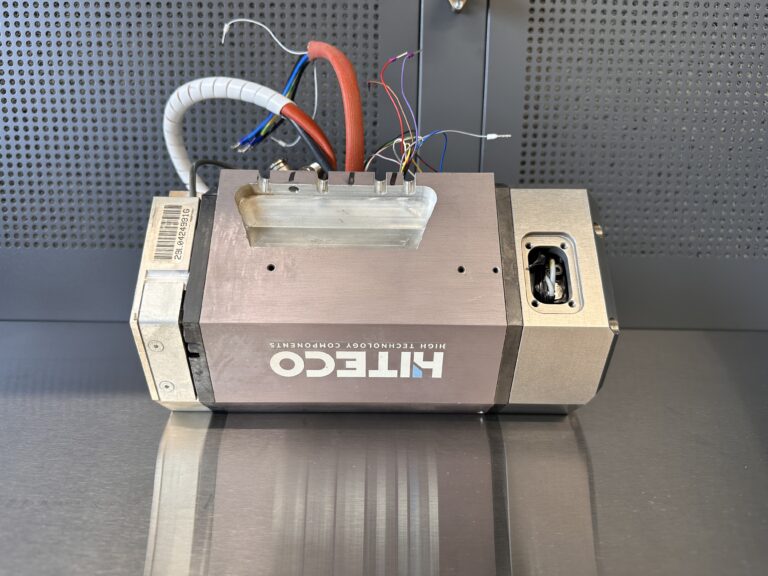

Hiteco Spindle Repair and Service

We offer comprehensive refurbishment of Hiteco spindles – the Italian manufacturer of high-speed electrospindles used in CNC machines. We guarantee fast diagnostics, precise repair, and complete service documentation.

Hiteco

Spindles

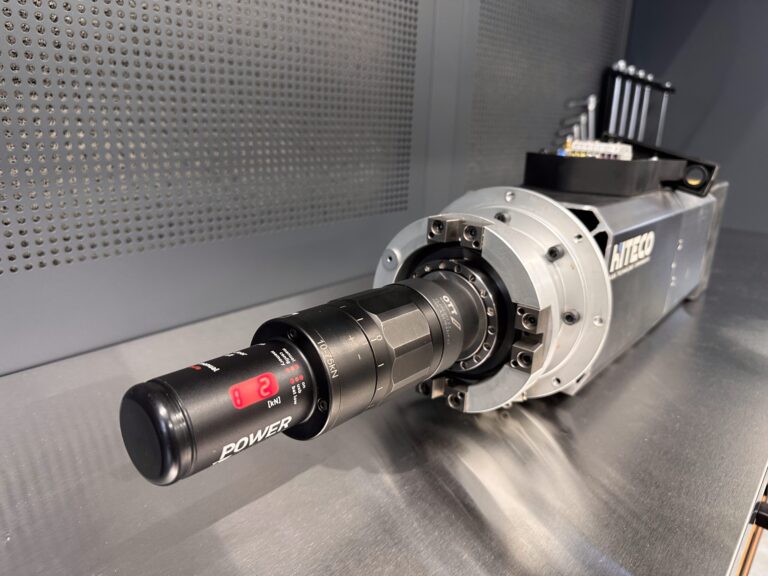

Hiteco is a renowned manufacturer of electrospindles used in CNC machines for woodworking, plastics, and metal processing. These spindles are valued for their compact size, reliability, and high-precision performance at high rotational speeds.

Despite their high-quality design, Hiteco spindles – like any mechanical device – are subject to wear. Typical failures include damage to bearings, sensors, rotors, or cooling systems. In our service center, we offer a full range of repairs based on the manufacturer’s technical documentation.

Case studies

repair of Hiteco spindles

Professional Hiteco Spindle Service

Step by Step

We service Hiteco spindles according to a strict procedure that ensures full functionality is restored. The service process includes the following steps:

Initial Inspection and Testing

Disassembly and Cleaning

Damage Assessment

Geometry Measurement

Motor Rewinding

Bearing and Seal Replacement

Dynamic Balancing

Assembly and Final Testing

In our service center, we support popular Hiteco models: Air Power, Electrospindle, Fan-cooled, and ATC versions. Each refurbishment is documented and comes with a warranty.

Need to repair your

Hiteco spindle?

Call or write to us – we’ll provide a quote and arrange a convenient service date. We work with clients from Poland and across the European Union.

We offer fast spindle pickup by courier and complete post-service documentation.

CONTACT