Kessler Spindle Repair and Service

We specialize in professional refurbishment and repair of Kessler electrospindles – one of the leading spindle manufacturers used in CNC machining centers. We provide comprehensive diagnostics, fast lead times, and top-quality workmanship backed by years of experience.

Kessler

Spindles

Kessler is a renowned German manufacturer of spindles used in modern machining centers. These devices are characterized by precise craftsmanship, excellent operating performance, and integration capabilities with advanced cooling and control systems. They are found in machines from many recognized brands around the world.

Like any mechanical device, Kessler spindles undergo natural wear and tear. Common failures include worn bearings, winding damage, sensor malfunctions, or a drop in clamping force. Through precise refurbishment, we restore full functionality and original factory parameters.

Case studies

repair of Kessler spindles

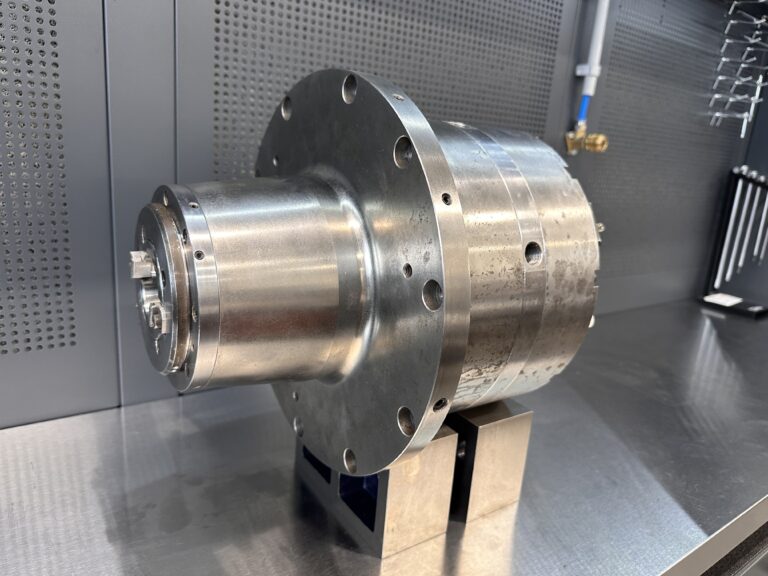

KESSLER Spindle Repair on DMG CMX 1100 V

The complete overhaul of the KESSLER spindle in our workshop restored factory precision an...

Read moreProfessional Kessler Spindle Service

Step by Step

Kessler spindles sent to our service center go through a multi-stage refurbishment process. With our expertise and experience, we guarantee repairs that meet both manufacturer specifications and the expectations of industrial users.

Initial Diagnostics and Testing

Disassembly and Component Cleaning

Technical Condition Assessment

Coil Rewinding

Sensor Refurbishment and Calibration

Working Surface Refurbishment

Parts Replacement and Clamping Force Measurement

Dynamic Balancing and Assembly

Final Testing

We service popular Kessler models, including DMS 112, DMS 132, HSK63, HSK100, and others. We guarantee full compliance with manufacturer documentation.

Need to repair your

Kessler spindle

Contact our service team, and we will prepare a detailed quote and turnaround time for your repair. We serve clients from Poland and across Europe.

Feel free to contact us – we respond quickly and clearly. We guarantee service quality and full service documentation.

CONTACT