On-Site Taper Grinding

of Spindles in Machine Tools – SK / BT / ISO

On-site spindle taper grinding – precise taper restoration at the customer’s location, with minimal cost and zero machine downtime.

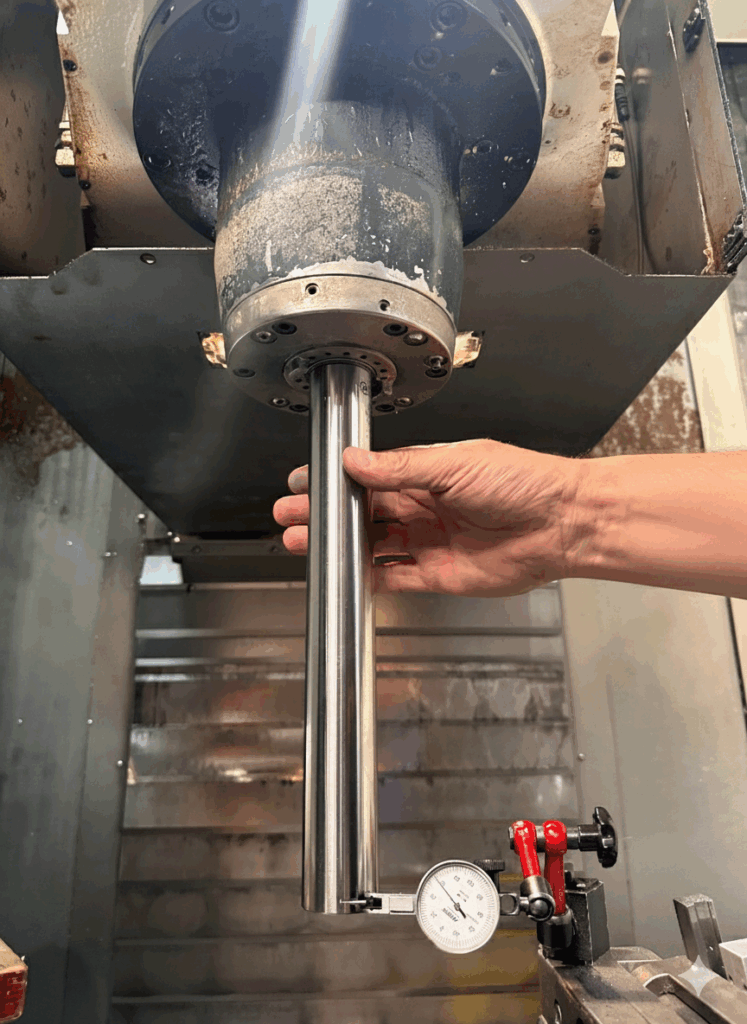

BMS Spindle Service CNC offers mobile grinding of SK, BT, and ISO tapers (sizes 30 / 40 / 50) without the need to disassemble the spindle, directly on the machine.

Our experienced mobile service operates across Europe, delivering spindle taper grinding within 24 hours. We restore the full contact surface of the taper and reduce runout to as low as 2 microns (0.002 mm), restoring OEM-level tool clamping precision.

Why On-Site Taper Grinding Is Best

for Maintaining Production Continuity

The CNC spindle taper is a critical interface between the tool and the machine – its geometry directly affects machining precision, stability, and safety. Wear or damage results in off-center tool holding, which negatively impacts the cutting process. Even minor taper deviations can cause serious issues:

- Weak tool holding – leads to reduced accuracy and poor part quality, and in extreme cases, tool dislodgement.

- Vibrations and excessive tool wear – increased instability during machining shortens tool life and may damage the machine, raising production costs.

Mobile spindle taper grinding restores ideal clamping geometry – improving tool holding force, reducing runout, and ensuring full stability of the machining process. This service quickly eliminates the above issues while maintaining the highest CNC precision and minimizing downtime.

Process of Mobile

Spindle Taper Regrinding

Each mobile spindle taper grinding service follows a proven five-step process. This allows us to fully restore the spindle taper geometry to OEM standards without disassembly. Below we present the step-by-step process carried out directly at the customer’s site:

Most common spindle taper issues

and how to fix them

Spindle taper runout

Excessive runout causes vibrations, reduces tool life and machining accuracy.

Solution – Mobile taper grinding reduces runout to as low as 2 μm and restores axis alignment.

Taper surface wear

Scratches and irregularities weaken contact between the tool holder and spindle.

Solution – Taper regrinding restores smoothness and OEM contact geometry.

Unstable tool clamping

Looseness in the taper reduces machining accuracy and may cause tool ejection.

Solution – Taper grinding ensures full contact surface and secure tool clamping.

Frequently

Asked Questions

Mobile Taper Grinding SK / BT / ISO

to OEM Standard

Use our mobile taper grinding service to restore full geometry and clamping force without taking the machine out of production. We work on-site with top quality standards.

-

Restoration of SK, BT, ISO tapers (30 / 40 / 50) to OEM specification

-

In-situ grinding – no spindle removal required

-

Precision up to 0.002 mm – verified by measurements

-

Mobile service – 24h response, available 24/7

Contact us and order the service. We will ensure perfect clamping and top CNC machining quality.

Request a quote