Spindle clamping force

calibration and measurement

Tool clamping force calibration – safety and machining stability.

Correct clamping force is essential for precise and safe CNC machine operation. Wear, contamination or mechanical misalignment can weaken clamping, cause tool holding issues or even damage the spindle.

At BMS Spindle Service, we offer clamping force measurement and calibration to ensure your tool holding system works according to factory specifications. We use precise instruments to check spring clamping force and mechanical systems.

Regular clamping force control increases workplace safety, improves machining quality and extends the service life of both spindle and cutting tools.

Why tool clamping force

is essential for quality and durability

Correct tool clamping force in the CNC spindle directly affects machining quality and the durability of both tools and the spindle itself.

Too little clamping force or even NO CLAMPING at all can pose a serious risk TO THE OPERATOR’S HEALTH AND SAFETY

If the clamping force is too low or uneven, it may lead to:

- Tool runout and dimensional errors on parts.

- Vibrations that reduce surface finish quality.

- Excessive wear on tools and spindle.

Regular clamping force calibration allows precise adjustment of the clamping mechanism, minimizing the risk of errors and production losses.

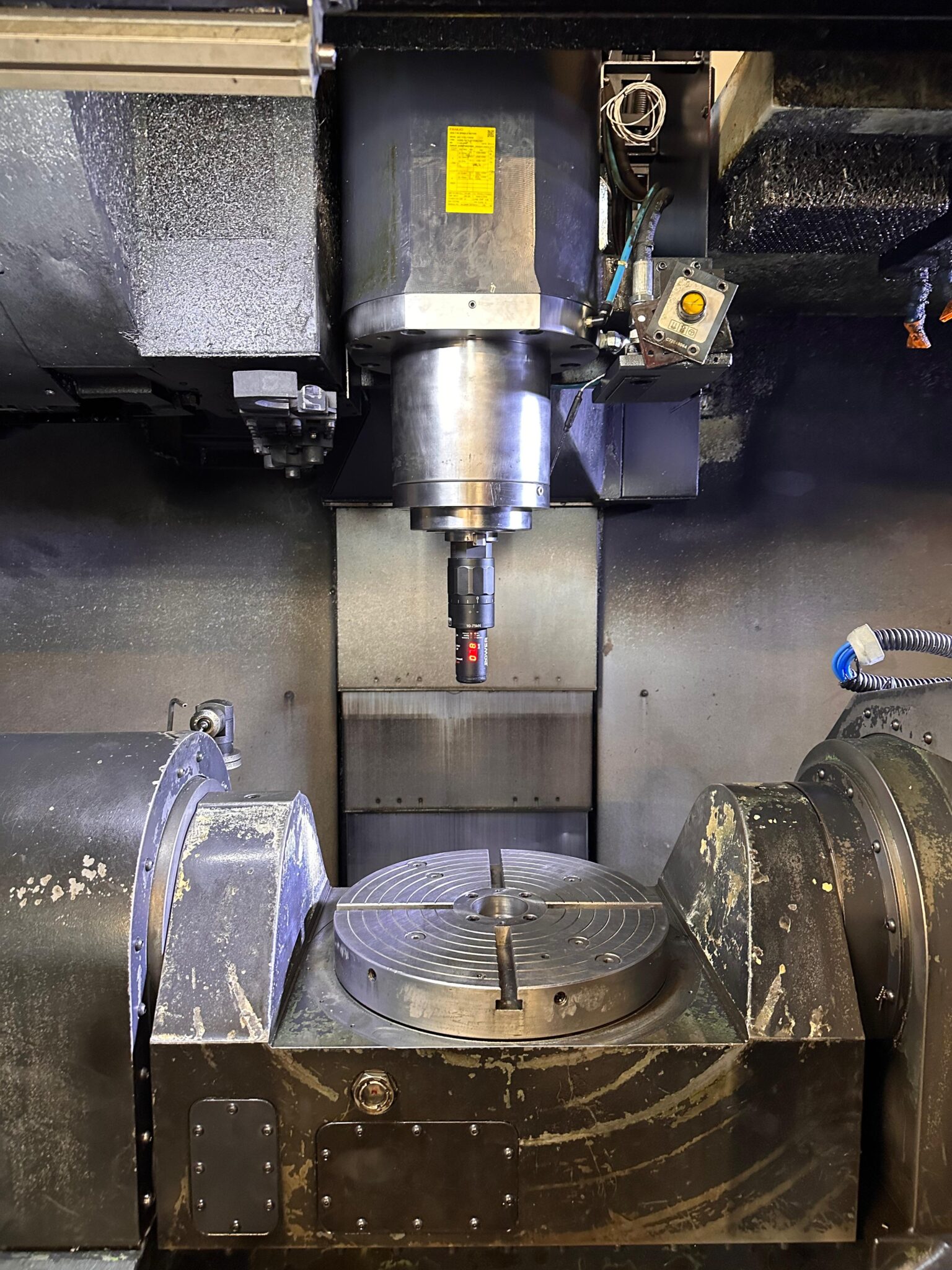

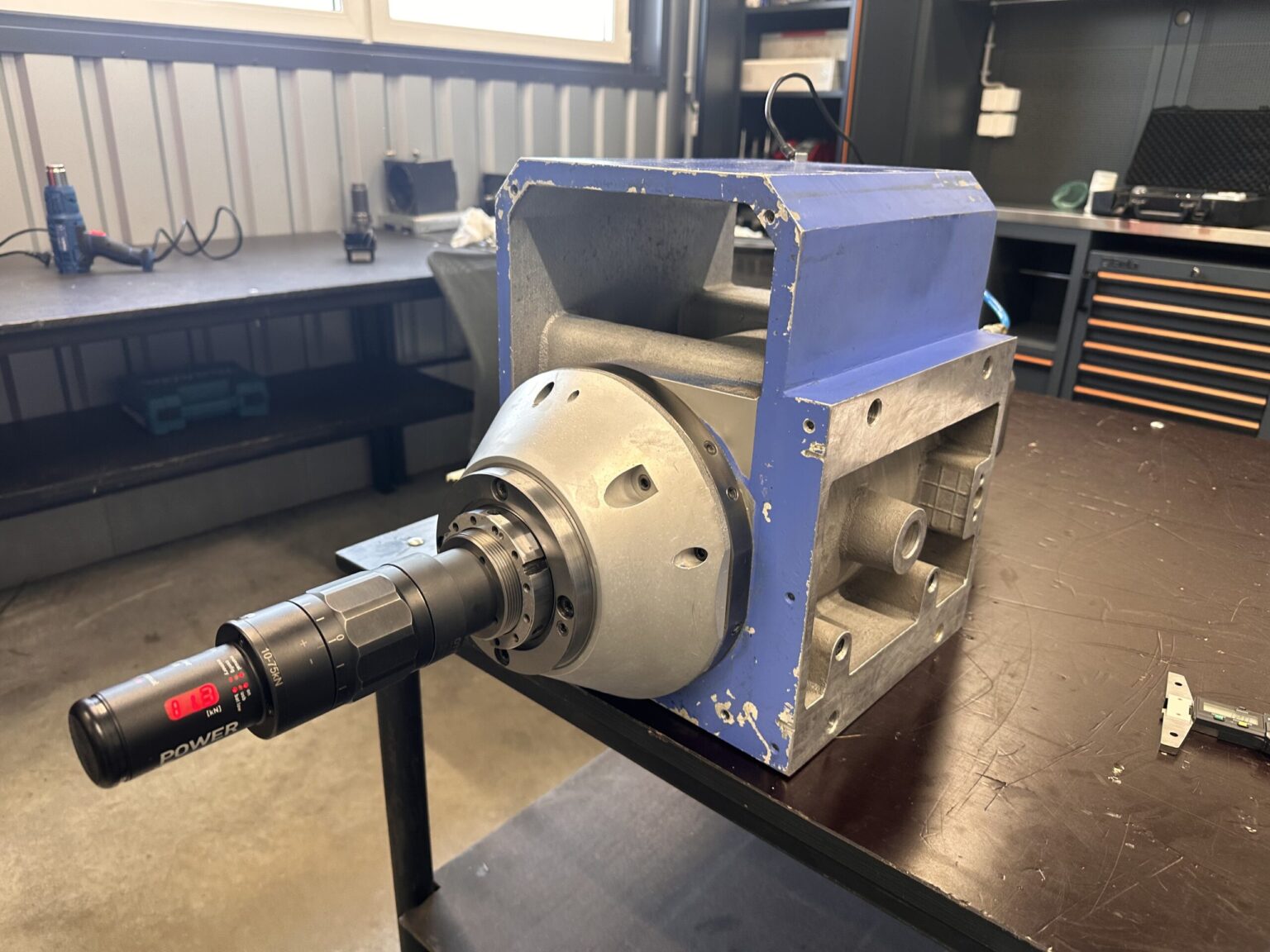

Spindle clamping force calibration

step by step

Each spindle clamping force calibration at BMS Spindle Service begins with a thorough diagnosis of the tool clamping system. By using certified force gauges and analyzing the components responsible for clamping pressure, we can precisely adjust the system in accordance with OEM standards and ensure consistent and safe tool holding.

Common clamping force issues

and how to fix them

Weak tool clamping

The tool may slip or fall out, leading to machining errors.

Solution – Clamping calibration and replacement of damaged components restore stable tool holding.

Spindle runout after tool installation

Incorrect clamping force can cause tool instability.

Solution – Accurate adjustment of the clamping force eliminates vibration problems.

Uneven tool wear

Too much or too little pressure causes premature blade wear.

Solution – Clamping force adjustment ensures even wear and extends tool life.

Frequently

Asked Questions

Spindle clamping force

measurement and calibration

Ensure precise tool holding – request a clamping force test and avoid tool slippage or machining errors.

-

Precise tool clamping force measurements

-

Calibration according to OEM specifications

-

Certified measurement report

Request a quote