Spindle motor

repair

Spindle motor repair – restore full CNC efficiency.

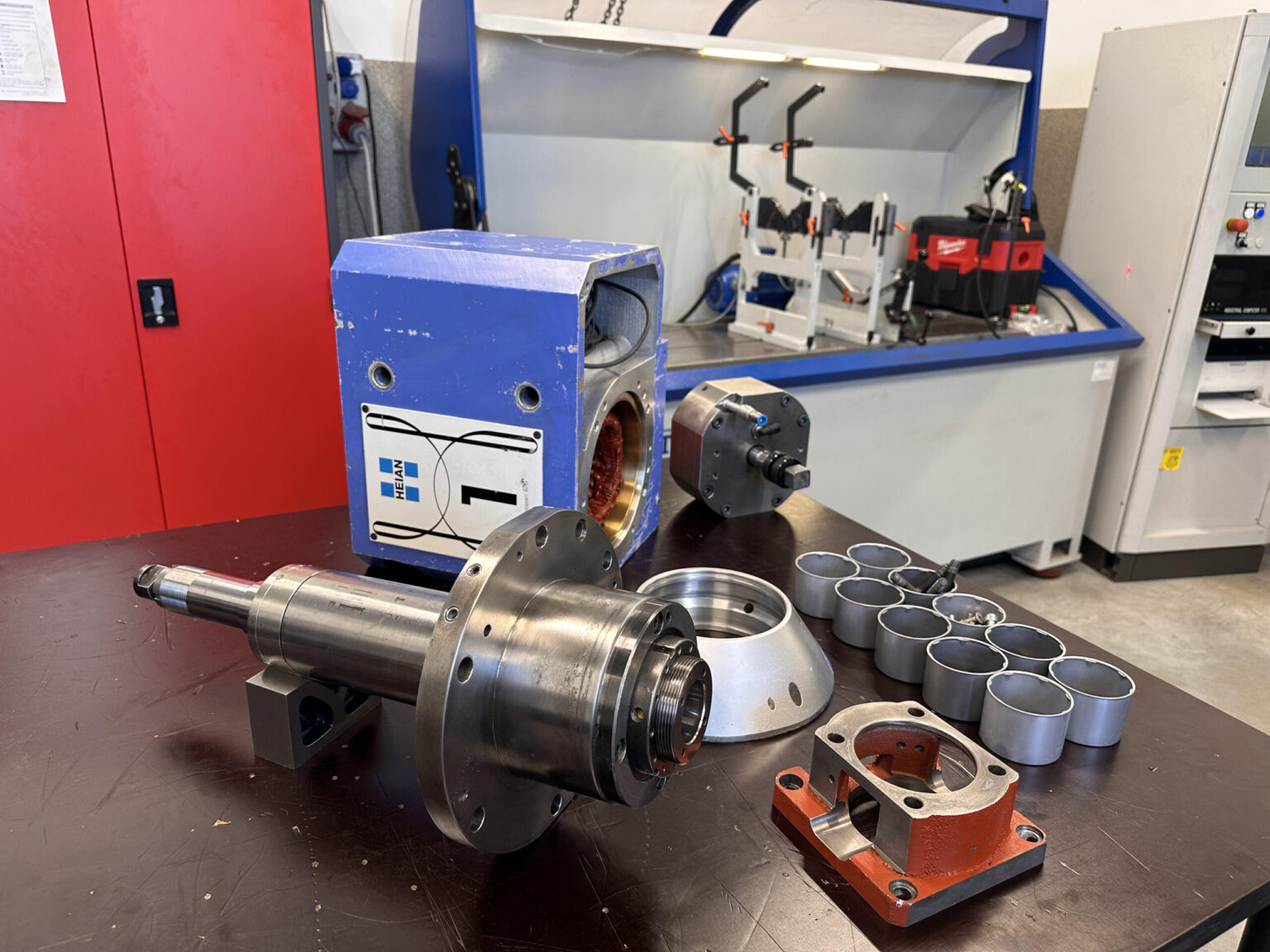

Electrospindles, as integrated motor units, require specialist repair procedures in case of failure.

Our service restores full functionality of spindle motors across all types of CNC machines.

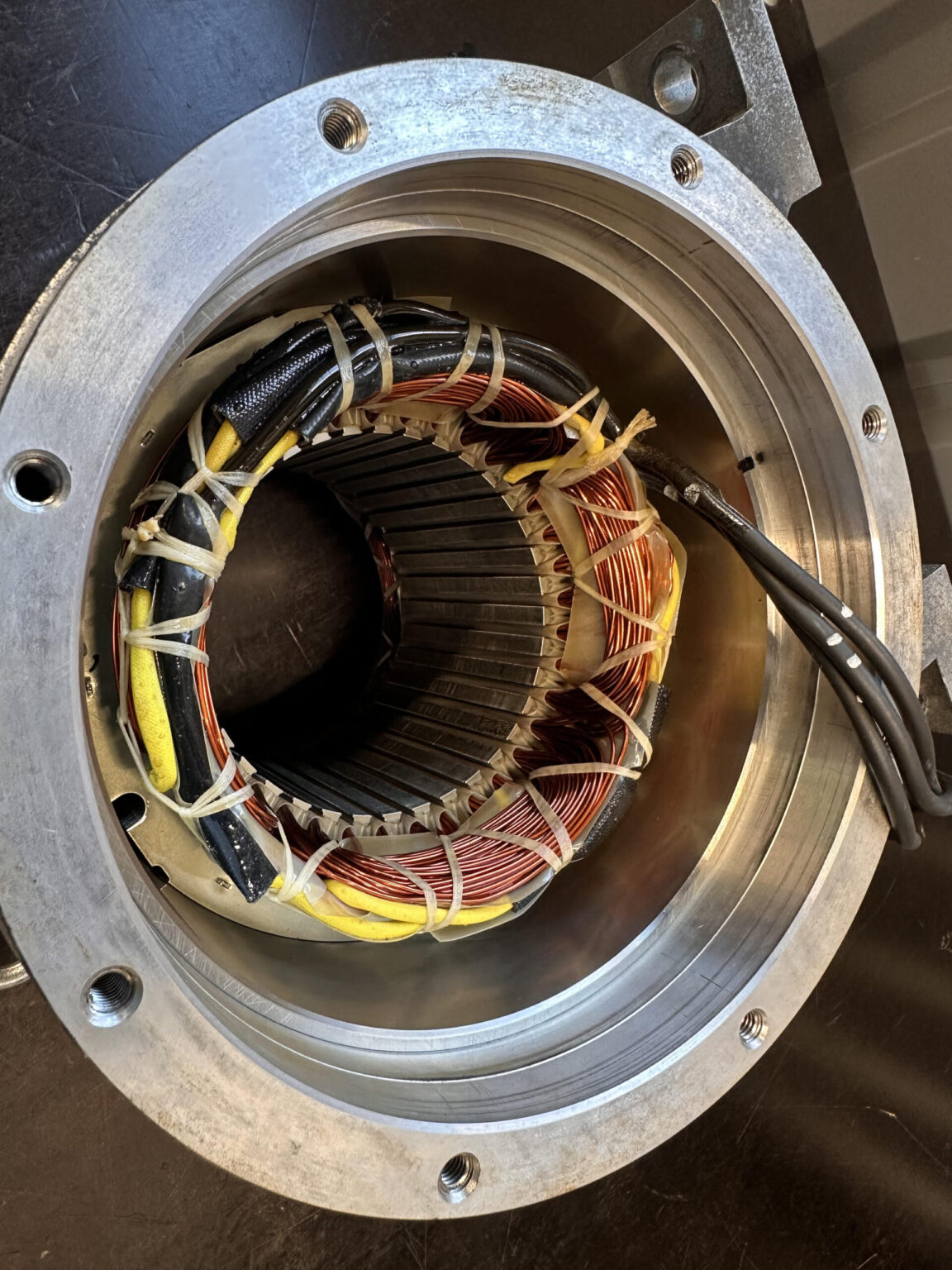

We carry out precise spindle motor repairs, including disassembly, diagnostics, rewinding of damaged windings, impregnation, reassembly, and testing of electrical parameters. If needed, we also replace bearings and perform dynamic balancing.

All repairs are performed according to OEM specifications, ensuring long service life, high efficiency, and reliability. We handle electrospindles from all manufacturers – for woodworking, aluminum machining, and precision applications.

Why is

spindle motor repair important

The CNC electrospindle is a critical machine component, responsible for high-speed machining operations. Damage to the motor windings directly affects the performance and reliability of the entire system.

Worn or damaged windings may cause:

- Loss of spindle power – resulting in reduced machining efficiency.

- Motor overheating – which can lead to severe damage and insulation failure.

- Unstable operation – such as irregular speeds and torque control issues.

Professional spindle motor repair restores full functionality, eliminates the risk of downtime, prevents costly failures, and ensures reliable production performance.

Spindle motor repair

step by step

The spindle motor repair process at BMS Spindle Service includes complete winding diagnostics, core cleaning, rewinding with H-class wires, dynamic balancing, and load testing. We aim to fully restore the original electrical and mechanical parameters, ensuring reliability at high rotational speeds.

Common winding failures

and how we fix them

Electrospindle overheating

Worn windings can cause excessive temperature rise during operation.

Solution – New insulation and winding repair eliminate overheating and improve spindle durability.

Loss of power and torque

Damaged windings fail to deliver sufficient energy to the motor.

Solution – Winding replacement and parameter tuning restore optimal performance.

Unstable motor operation, fluctuating RPM

Short circuits in the windings can lead to sudden voltage spikes.

Solution – Spindle rewinding restores smooth and stable rotation.

Frequently

asked questions

Spindle motor repair

by professionals

Damaged windings don’t mean the end of operation – we restore spindle motor performance with guaranteed reliability.

-

Thermal insulation and testing after motor repair

-

Electrical parameters restored to original factory levels

-

15 years of experience in spindle motor repair

Request a quote