Spindle taper

grinding service

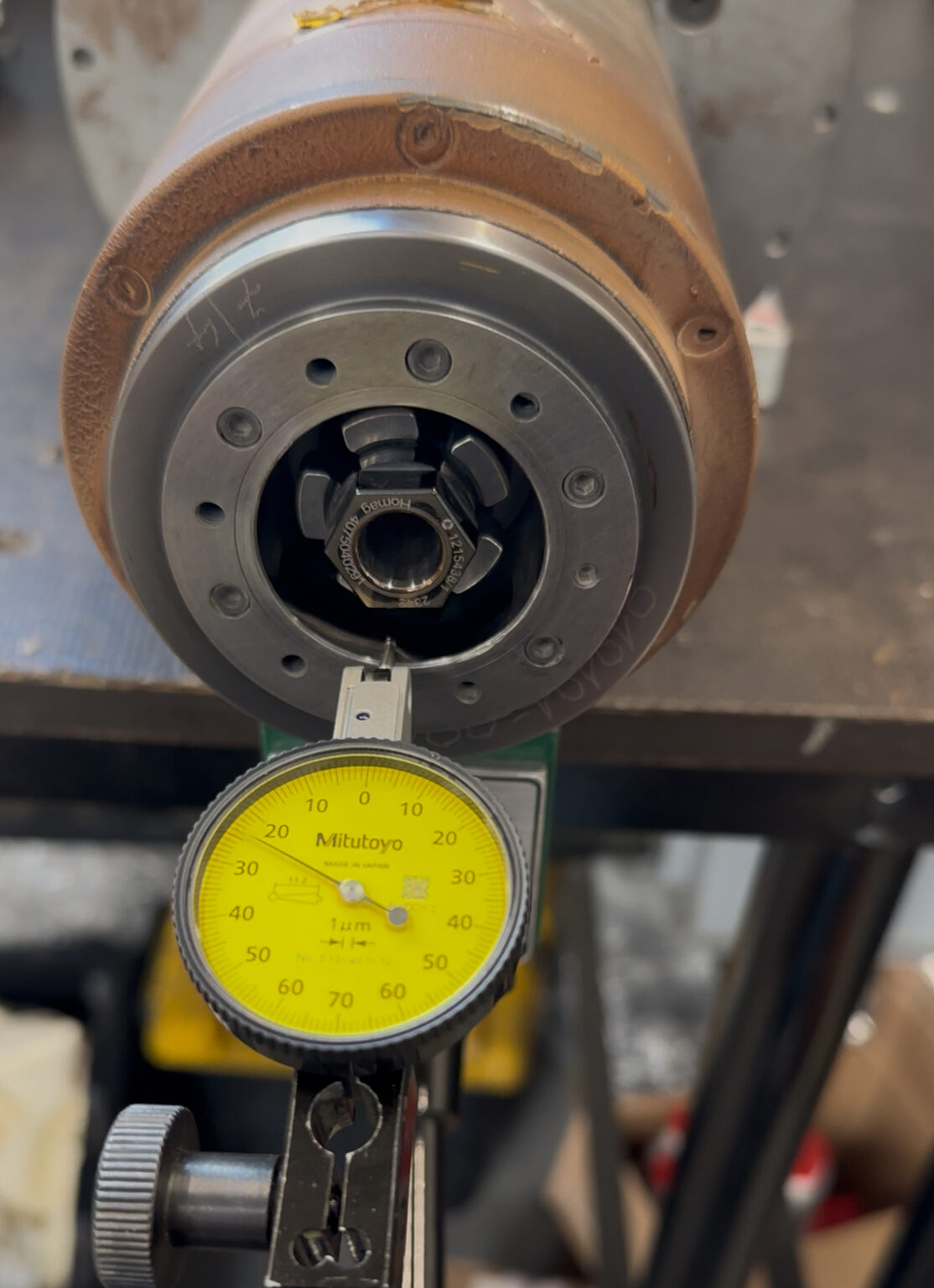

Spindle taper grinding – precise geometry, secure tool holding.

A worn or damaged spindle taper leads to improper tool holding, reduced machining accuracy, and accelerated machine wear.

We provide precise restoration of CAT, BT, HSK, ISO and other tapers – according to OEM standards. We also repair damaged threads

in ER tapers as part of the full grinding process.

Spindle taper grinding is a process of restoring the internal taper geometry by precise regrinding and alignment. The goal is to eliminate wear, runout, and surface damage that affect tool concentricity and holding force.

Our technicians perform taper regrinding with micrometric precision – both at our facility and as an in-situ service. This ensures perfect contact between the tool holder and the spindle taper, guaranteeing full machining accuracy.

Why spindle taper grinding

is crucial for precise tool holding

The spindle taper is the contact point between the CNC machine and the tool – its geometry directly affects machining accuracy, stability, and safety.

Even microscopic deviations can cause:

- Weak tool holding – leading to reduced precision and lower part quality.

- Vibrations and excessive tool wear – shortening tool life and increasing production costs.

Spindle taper grinding restores perfect clamping geometry – improving holding force, reducing runout, and increasing overall machining stability.

Spindle taper repair

step by step

Every spindle taper repair at BMS Spindle Service follows a multi-stage, precision process aimed at restoring the taper geometry and surface quality to OEM standards. This ensures consistent tool clamping and the highest machining accuracy.

Common spindle taper problems

and their solutions

Tool holding issues

Tools may rotate or fall out of the spindle.

Solution – Grinding the spindle taper ensures perfect contact and secure tool clamping.

Tool vibration during machining

A worn spindle taper causes instability during operation.

Solution – Taper calibration and grinding reduce runout and improve stability.

Visible wear marks on the taper

Surface irregularities may cause dimensional inaccuracies in machined parts.

Solution – Precision spindle taper grinding removes scratches and restores proper contact.

Frequently

asked questions

Taper reconditioning

according to OEM standards

Restore the full geometry and clamping force of HSK, BT, SK or ISO tapers with our precision reconditioning process.

-

Reconditioning of all toolholder taper types

-

Axial and radial runout measurement

-

Precision machining of tapers

Request a quote