Powermat 1500 WEINIG Spindle Repair

Full repair of WEINIG spindle

from Powermat 1500 planer

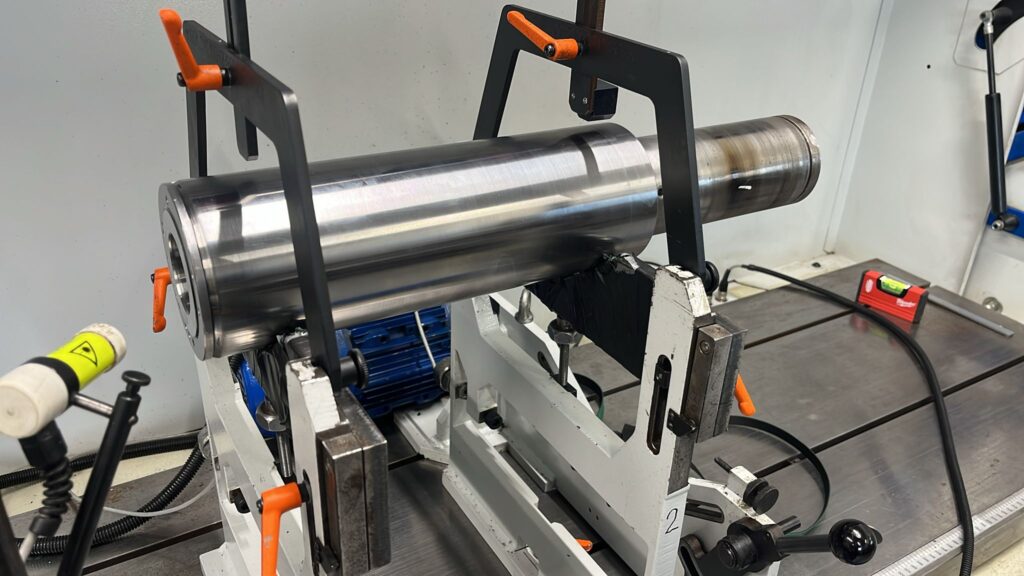

At our service center, we carried out a complete repair of a WEINIG spindle from a WEINIG Powermat 1500 planer, which arrived in exceptionally poor technical condition. Below we present the details of the work performed.

Diagnosis

severe spindle damage due to bearing failure

The spindle was damaged due to running with a seized bearing, which led to serious consequences:

- Tool gripper rubber melted due to overheating,

- Seized spindle shaft requiring repair,

- Significant wear of the spindle housing.

WEINIG Spindle

repair stages

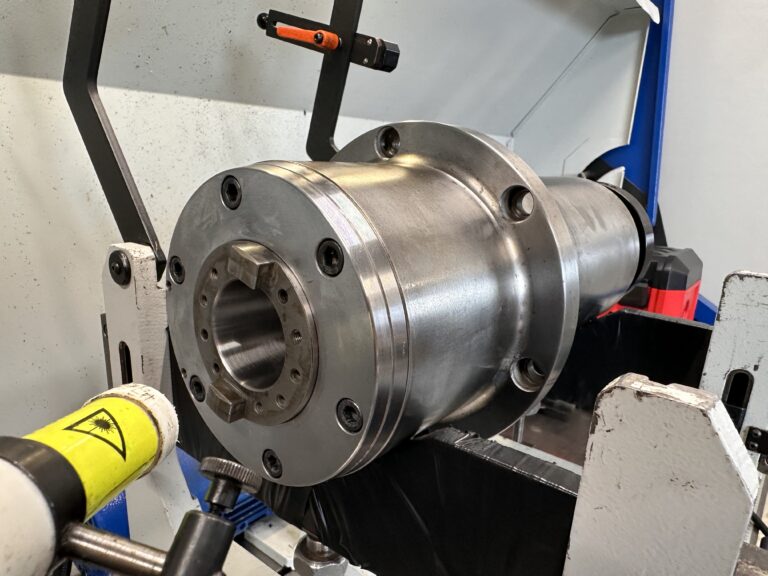

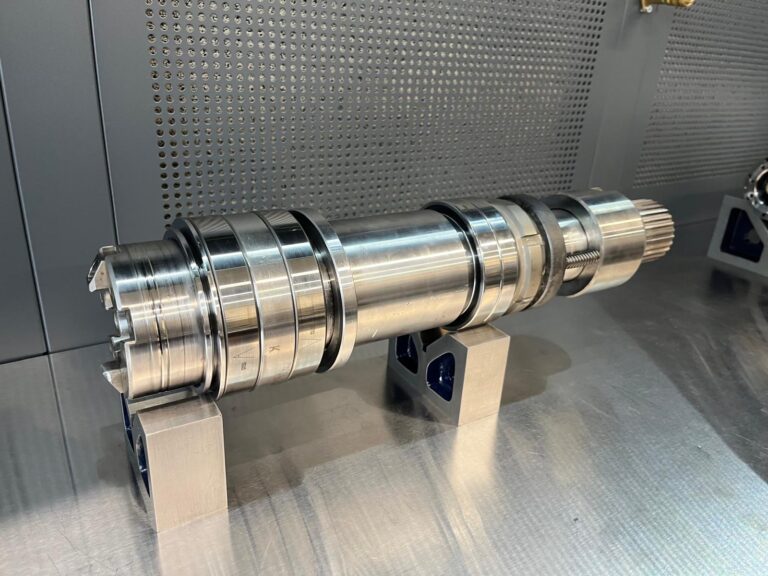

After disassembly, we fully replaced the spindle bearings with new ones, restoring reliability and machining precision.

The overheated and worn HSK taper was carefully ground and restored to factory tolerance, ensuring proper tool clamping.

The damaged clamping assembly was replaced with a new unit, restoring full functionality to the drawbar mechanism.

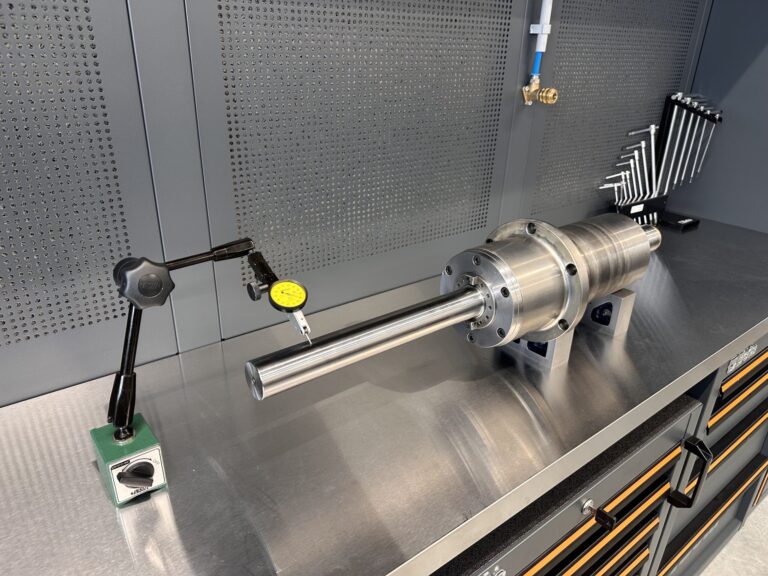

The spindle was dynamically balanced to 0.4G accuracy, minimizing vibration and ensuring smooth operation at high speeds.

We conducted full functional tests after the repair. The spindle was prepared for long-term use in the WEINIG Powermat 1500 planer and handed over ready for installation.

Professional WEINIG spindle repair

Trust our experience

Even heavily damaged spindles can be effectively repaired.

Thanks to our team’s experience and a modern service facility, we restore even the most worn-out WEINIG units to full working condition.

Every WEINIG spindle repair comes with a full 6-month service warranty.

We provide top-quality workmanship and peace of mind that your spindle will operate reliably.

Need WEINIG spindle repair? Contact us — we’ll restore your machine’s performance!