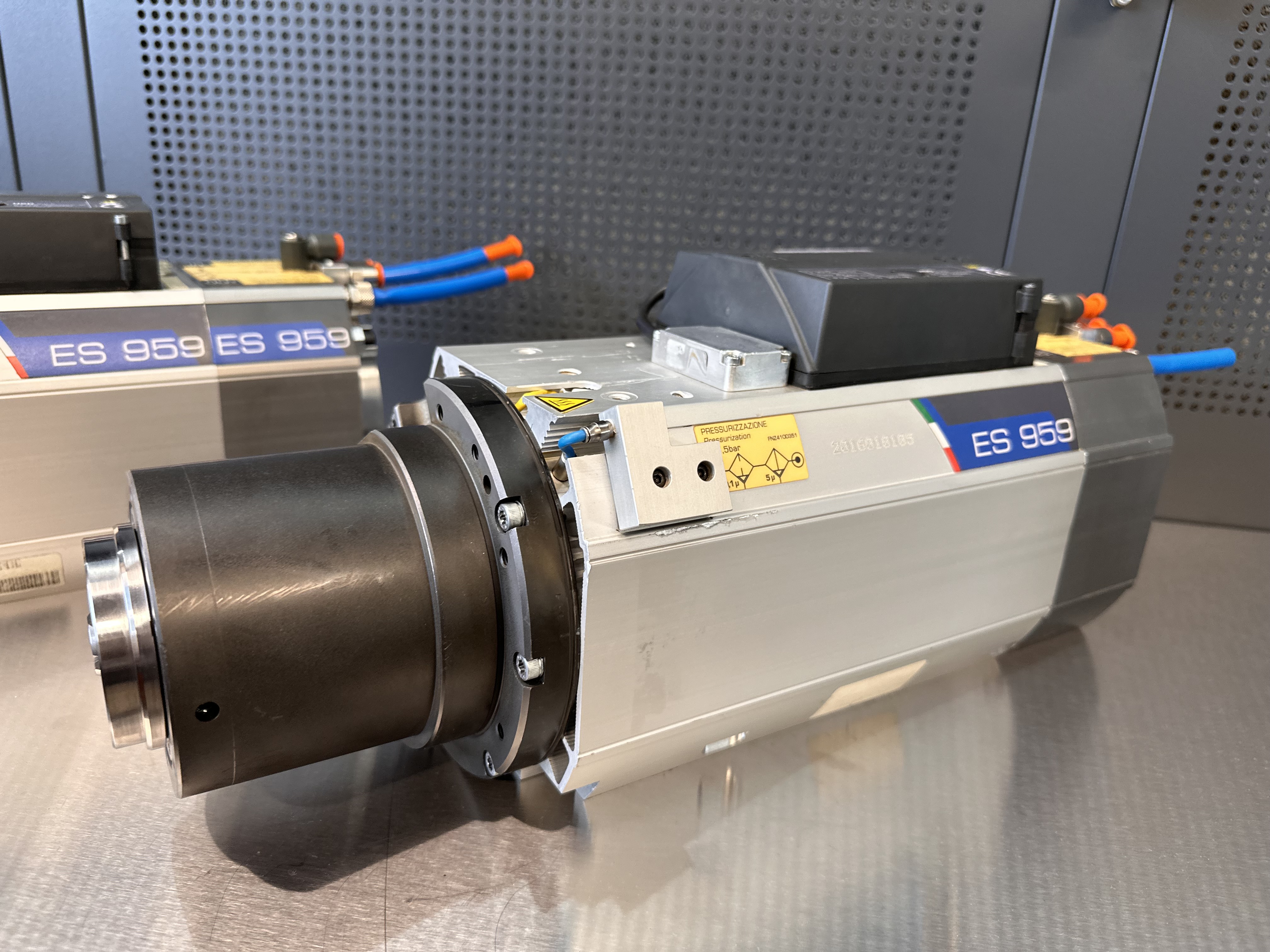

HSD ES 959L Electrospindles Repair

ROVER center service – repair of three HSD ES 959L units with unusual failures

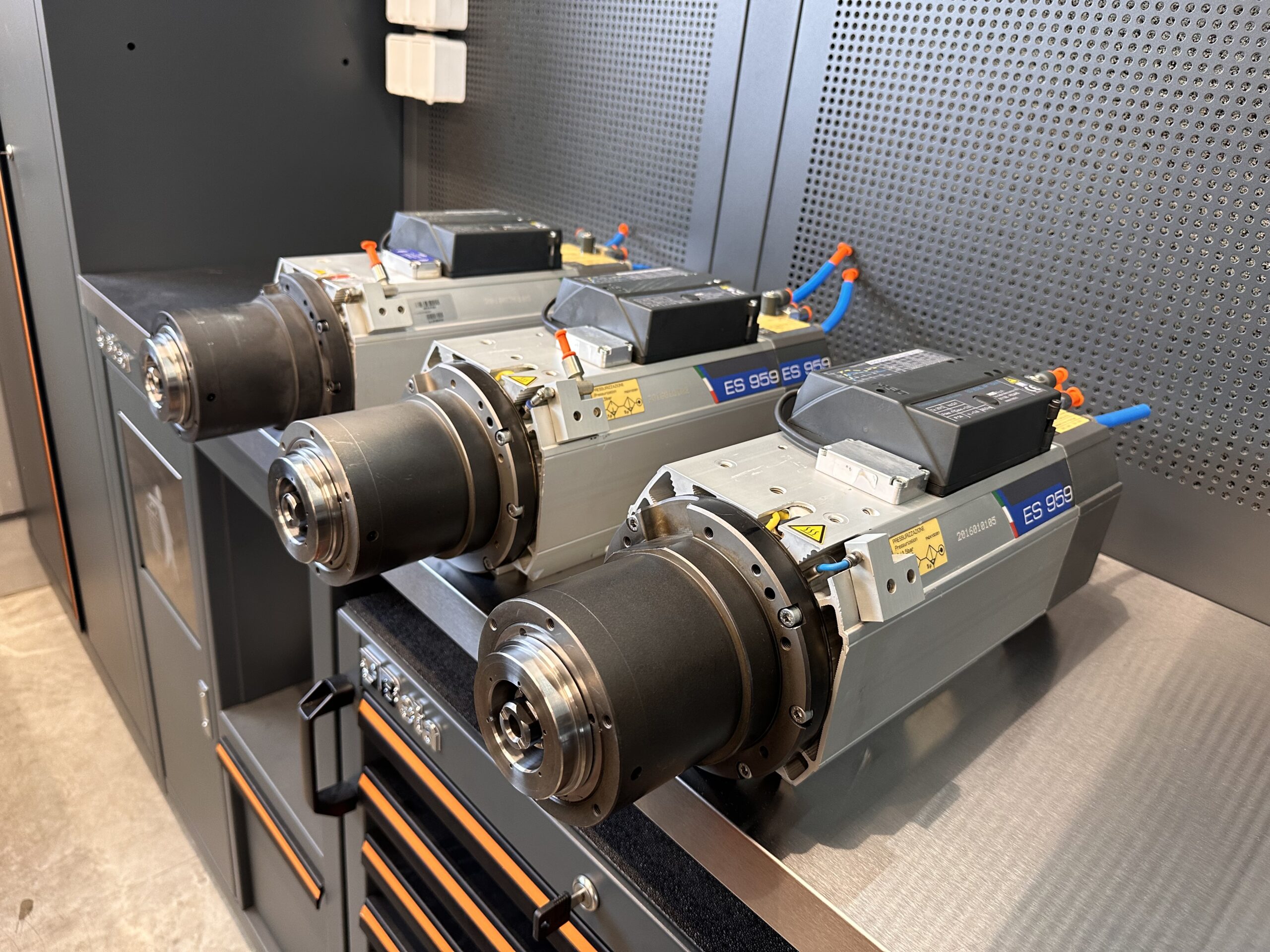

Our CNC service received as many as three HSD ES 959L electrospindles designated for operation in a machining center ROVER B. Two of them were sent as damaged units, while the third one was marked by another service as "beyond repair" and intended as a donor for spare parts.

We took a comprehensive approach. Thanks to our advanced technical facilities and experience in servicing HSD electrospindles, we restored all three spindles to full working condition, as confirmed by our service reports and test results on the customer's machine.

Electrospindle specification:

-

Model: HSD ES 959L

-

Tool holder taper: HSK 63F

-

Rotational speed: 24,000 rpm

-

Machine: ROVER B machining center

Unusual failures?

That's our specialty

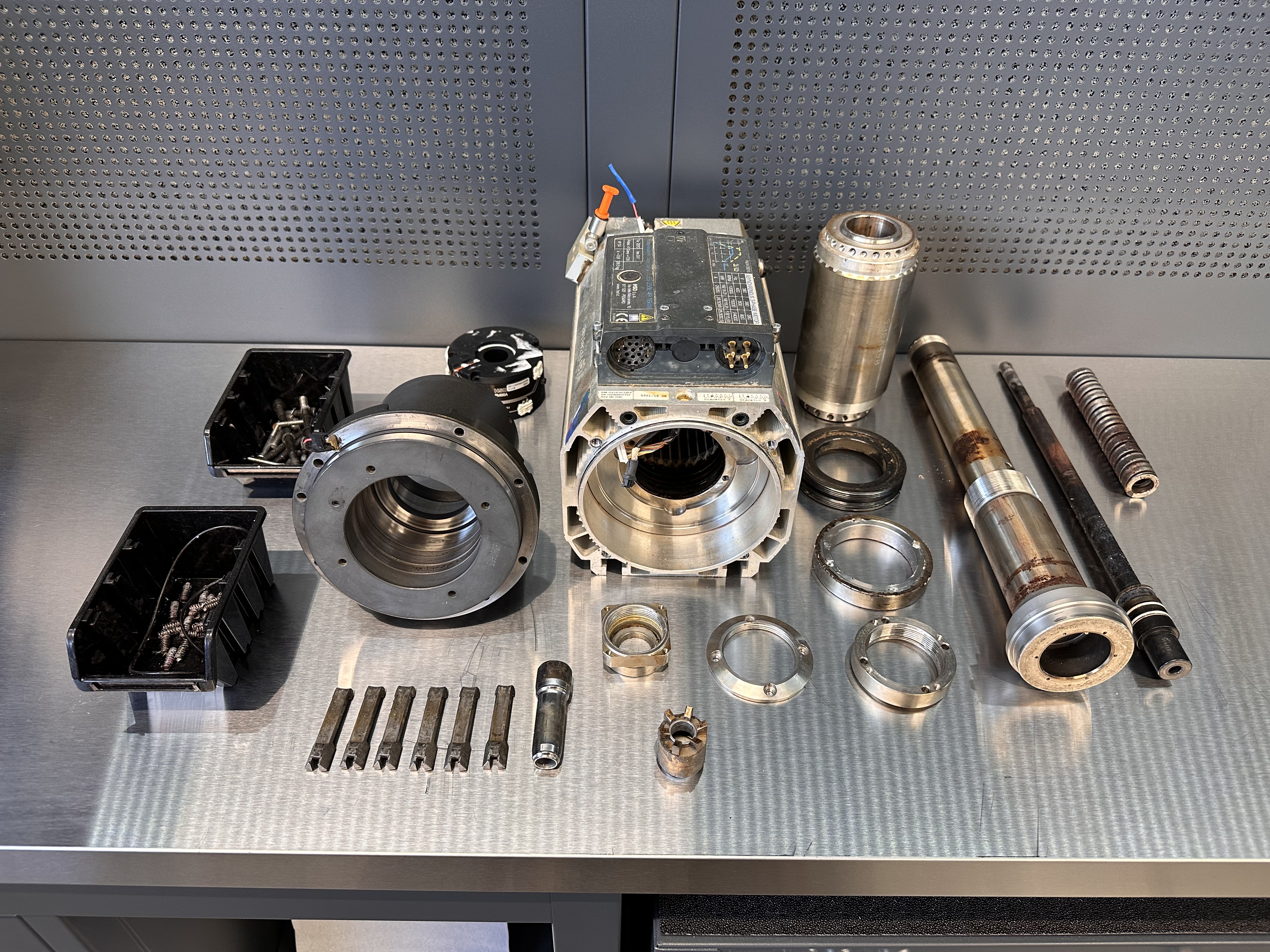

Many services avoid repairing electrospindles with non-standard failures – such as communication module damage or missing original components. In the case of HSD ES 959L electrospindles that reached us, we identified issues including:

- spindle communication with the machine's electronics,

- sensor malfunctions,

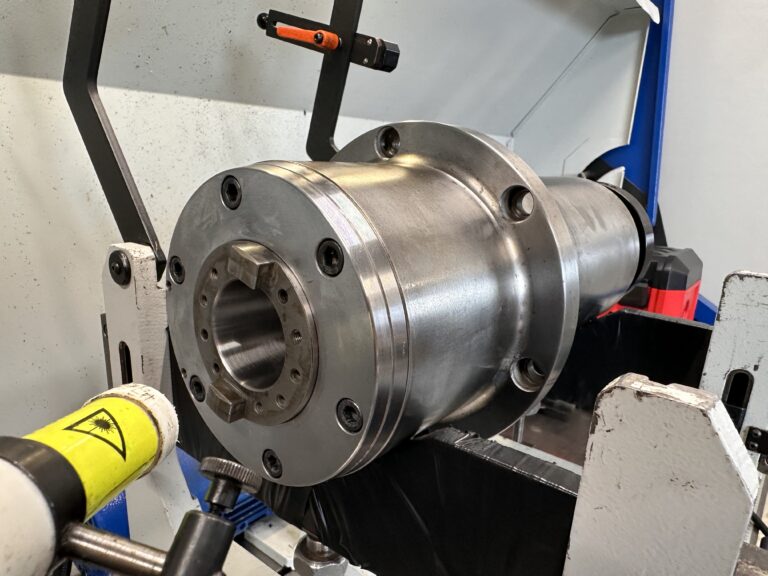

- tool taper deformation,

- severe wear of rotating components.

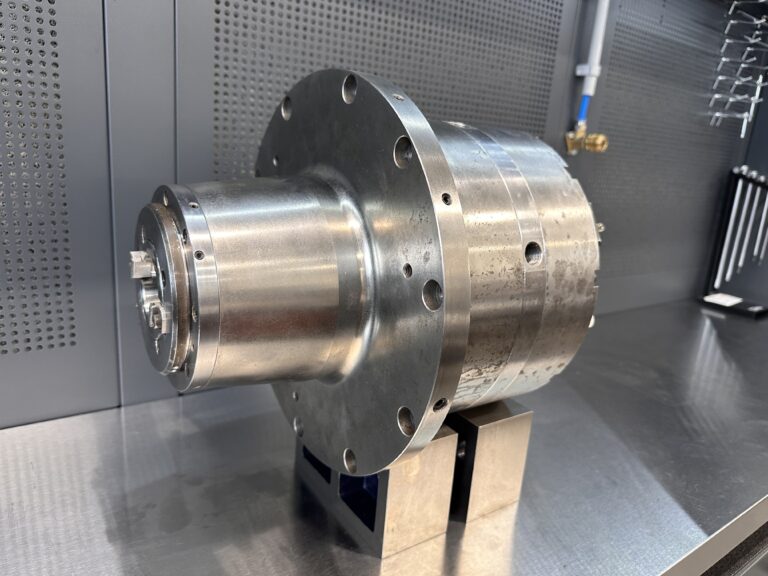

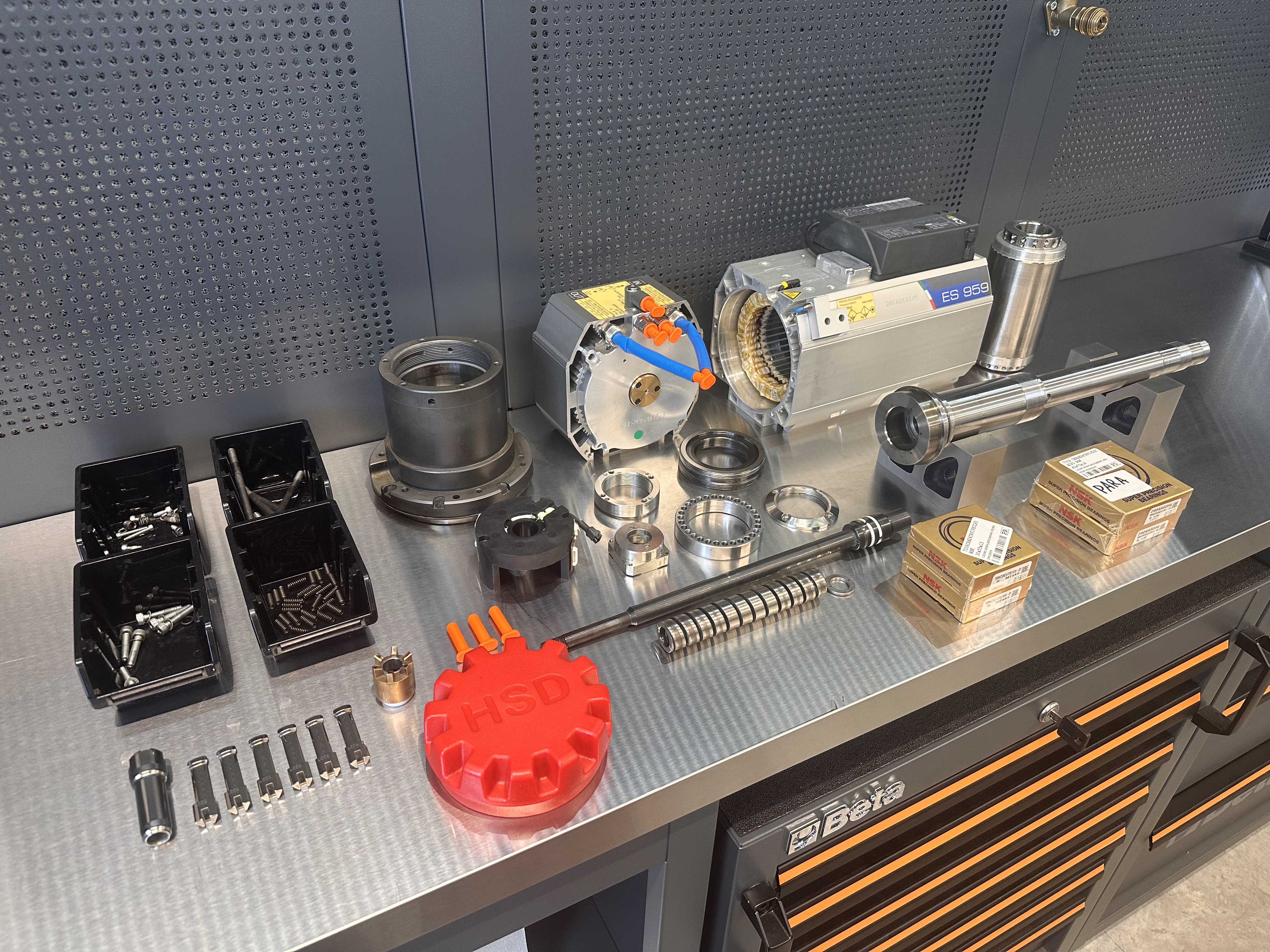

After thorough technical analysis, cleaning, and inspection, we decided to carry out a full regeneration of all three units.

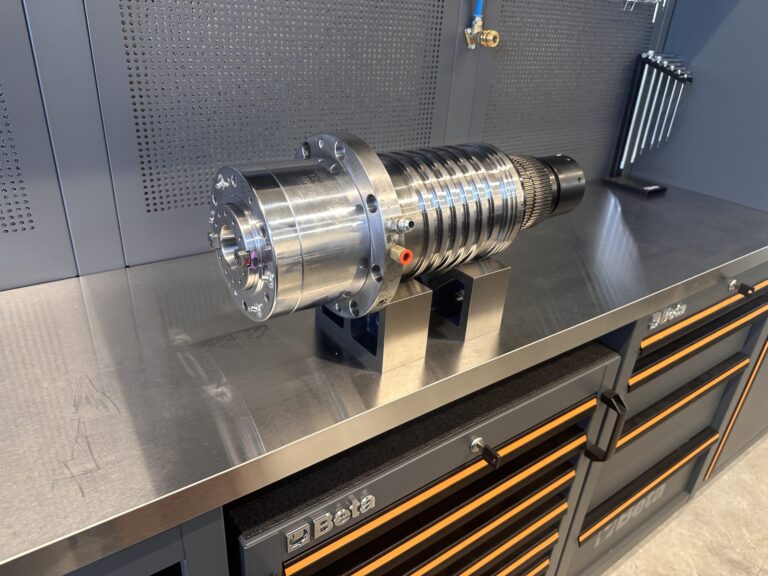

Scope of work performed

HSD ES during electrospindle regeneration

CNC spindle service

at the highest level

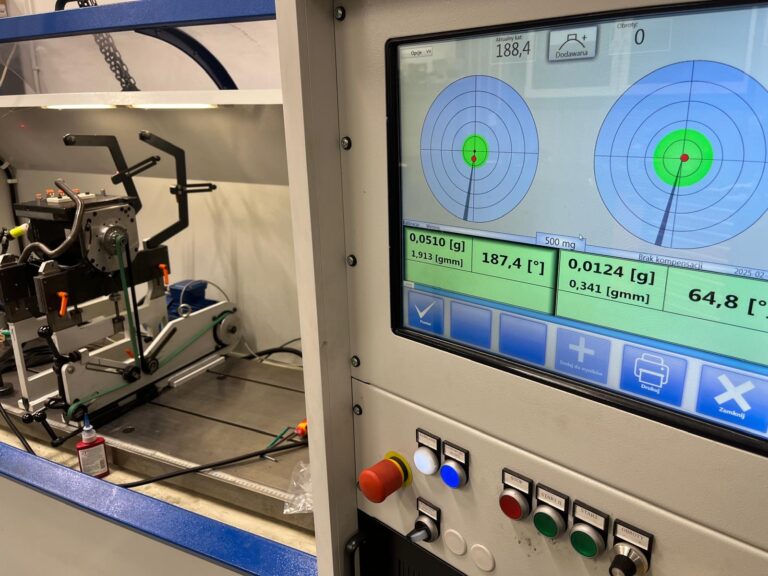

Our CNC spindle service includes full documentation of each repair. In this case, all key measurements and data were logged in our service reports:

- bearing clearance measurements,

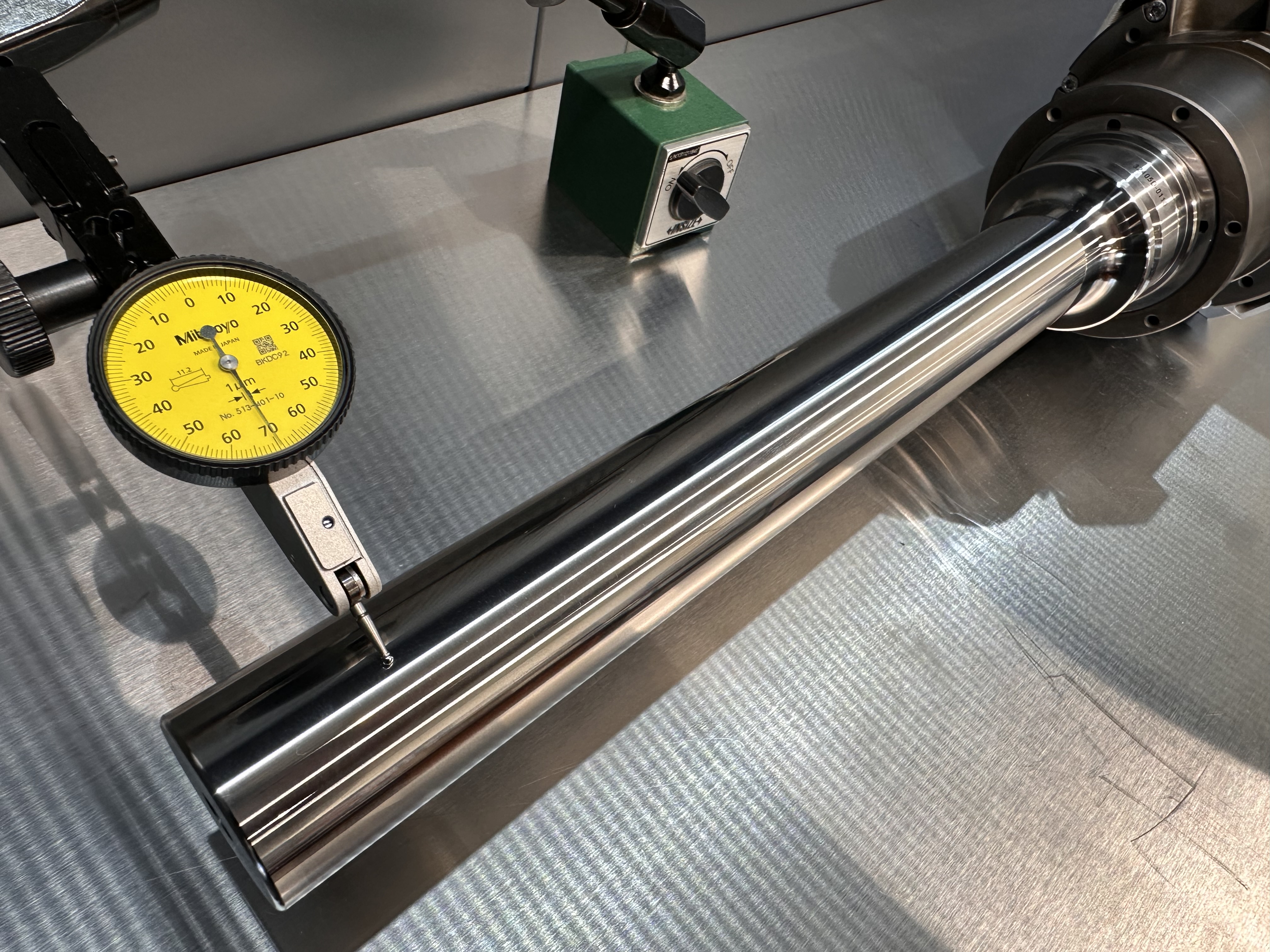

- spindle runout,

- tool clamping force,

- vibration and thermal tests,

- and final compliance with HSD factory parameters.

Thanks to this approach, we provide electrospindle repair even for units rejected by other services.