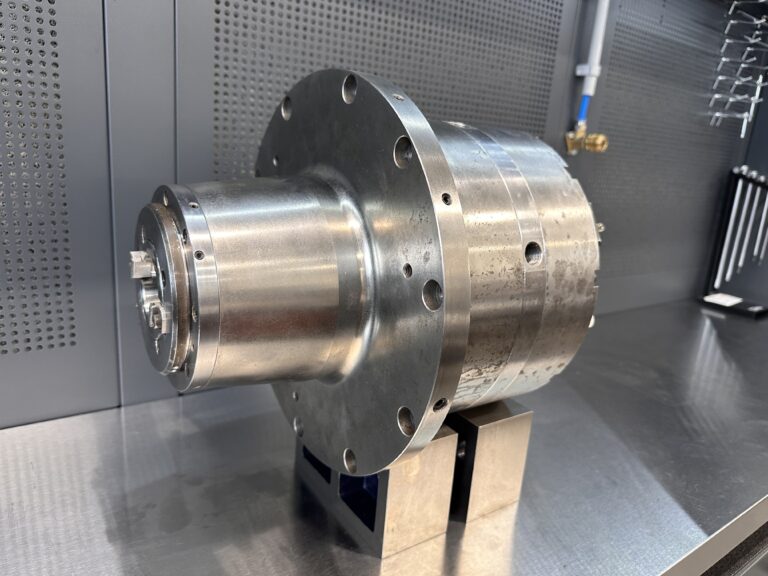

HITECO QX-2 11/12 24 63F NC Electrospindle Repair

Complete regeneration of a spindle for a 5-axis CNC machine

Our service received the HITECO QX-2 11/12 24 63F NC electrospindle, used in a five-axis CNC machining center. The unit, operating at 24,000 rpm with an HSK63F taper, showed signs of instability and system communication errors that made further operation impossible.

Electrospindle specifications:

-

Model: HITECO QX-2 11/12 24 63F NC

-

Tool taper: HSK 63F

-

Max speed: 24,000 rpm

-

Machine type: 5-axis CNC machining center

Diagnosis

and detected issues

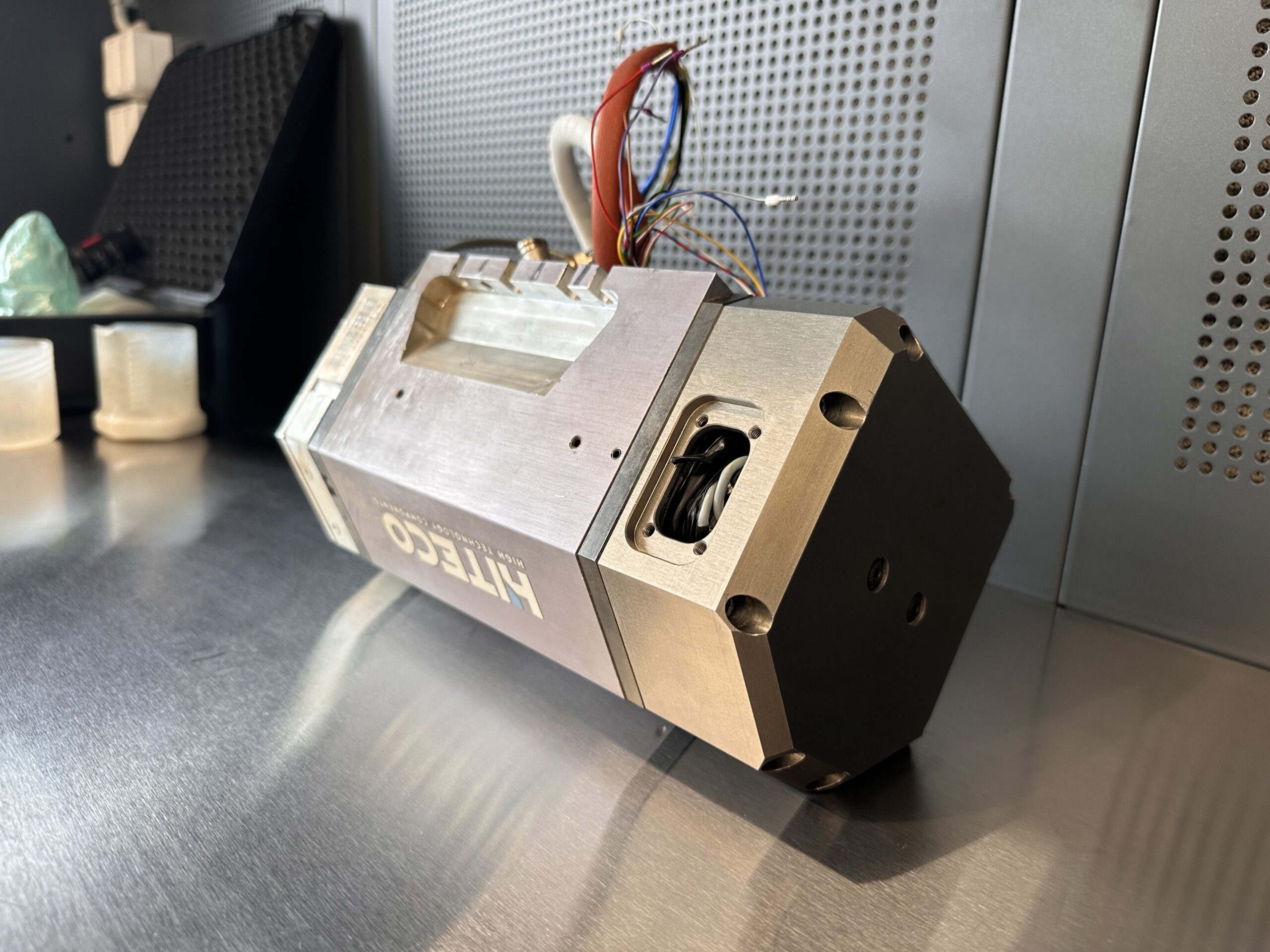

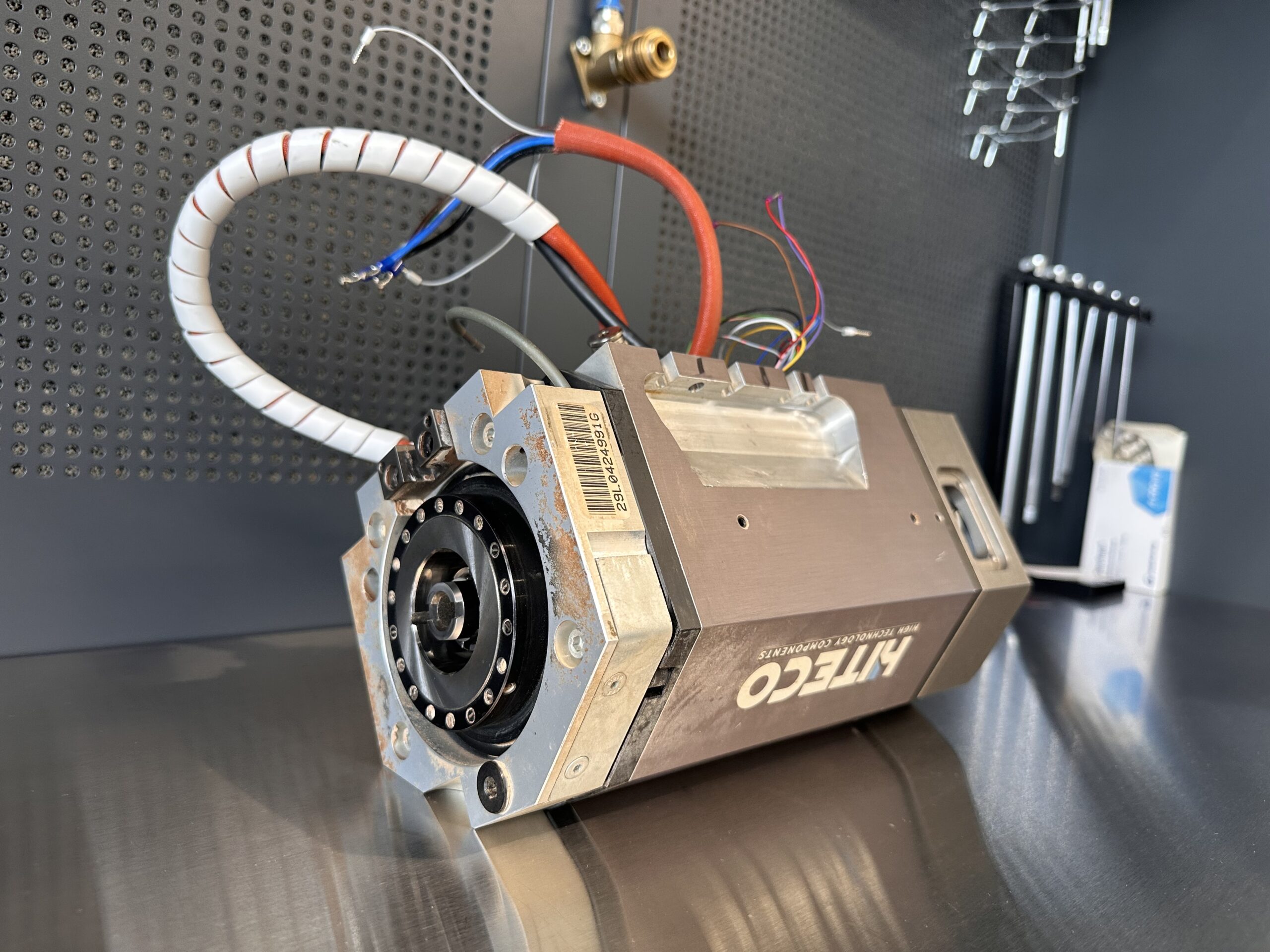

During the initial diagnostics stage, we confirmed several key problems:

- Damage to the electrical harness near the cooling channel transition,

- A faulty inductive sensor responsible for spindle positioning,

- Signs of improper balancing, causing vibrations during operation,

- Elevated housing temperature under load — indicating potential communication errors with sensors or the cooling system.

Stages of service performed

for HITECO QX-2 11/12 24 63F NC electrospindle

The service process was divided into key stages, with full documentation for each of them:

Why precision electrospindle service

matters

Servicing electrospindles like the HITECO QX-2 used in 5-axis machining centers requires precision, experience, and proper technical facilities. Unlike standard repairs, here even the slightest signal deviation or dynamic parameter anomaly can result in cutting errors, tool overheating, or costly production downtimes.

Trust experience

choose precision in HITECO electrospindle repair

If your electrospindle shows unusual symptoms or has been deemed irreparable — contact us. Our experience with electrospindles from HITECO HSD KESSLER DOOSAN, and many other manufacturers allows us to bring even the most challenging units back to life.