Haas Spindle Repair and Service

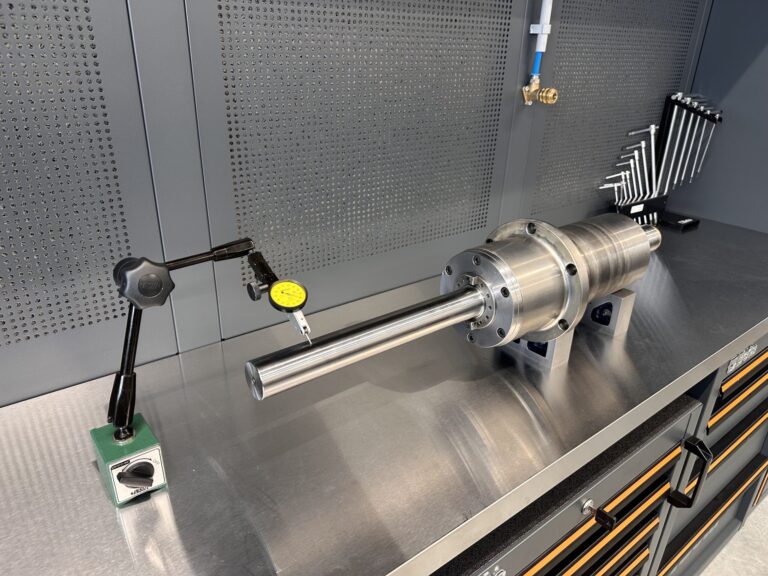

We provide specialized service for Haas spindles — the American manufacturer known for its reliable CNC machining centers. We refurbish vertical and horizontal axis spindles with full precision and technical compliance.

Haas

Spindles

Haas Automation is one of the largest CNC machine tool manufacturers in the USA. Their electric spindles are used in vertical machining centers and metal lathes. These spindles are known for their robust design, often based on precision bearings and direct-drive systems.

Over time, even with proper operation, spindle components wear out — most commonly bearings, sleeves, spacer rings, or cooling systems. In our service center, we carry out complete refurbishments using top-grade components.

Case studies

repair of Haas spindles

Professional Haas Spindle Service

Step by Step

Every Haas spindle that arrives at our workshop undergoes precise analysis and step-by-step refurbishment. Below are the stages of the service process:

Initial Inspection

Mechanical Disassembly

Cleaning and Parts Selection

Measurement and Testing

Refurbishment or Replacement

Balancing and Assembly

Final Testing

We repair Haas spindles for VF, ST, DT models and others. We always follow technical documentation and maintain the highest safety standards.

Need Your Haas

Spindle Repaired?

Contact our service — we’ll prepare a free quote, arrange a date, and provide full logistics support. We operate across all of Europe.

Call or write to us – we’ll respond quickly and clearly.

CONTACT