Blog

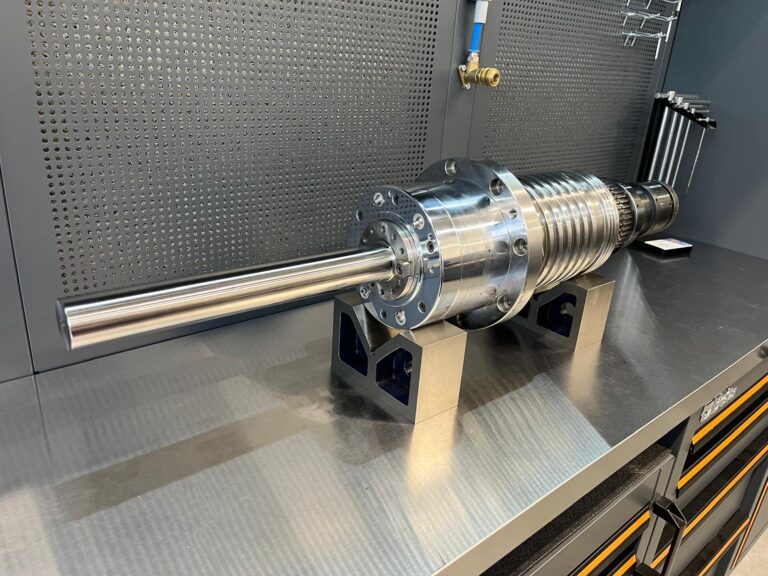

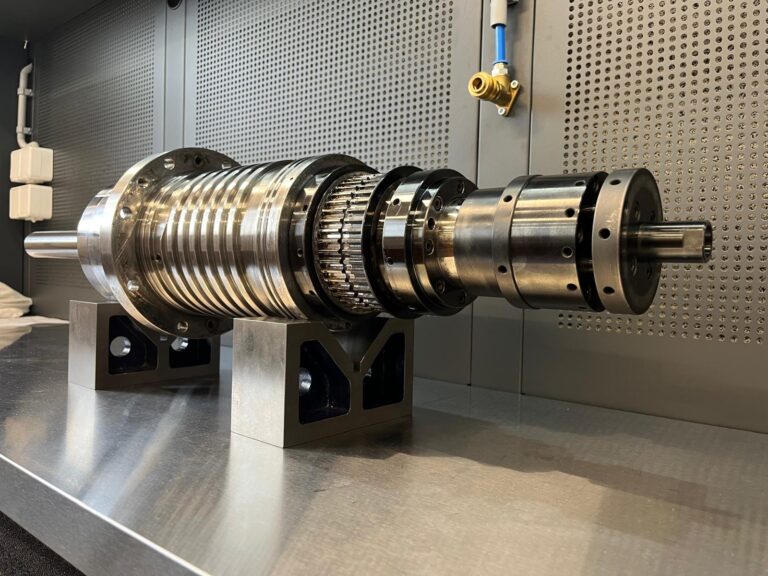

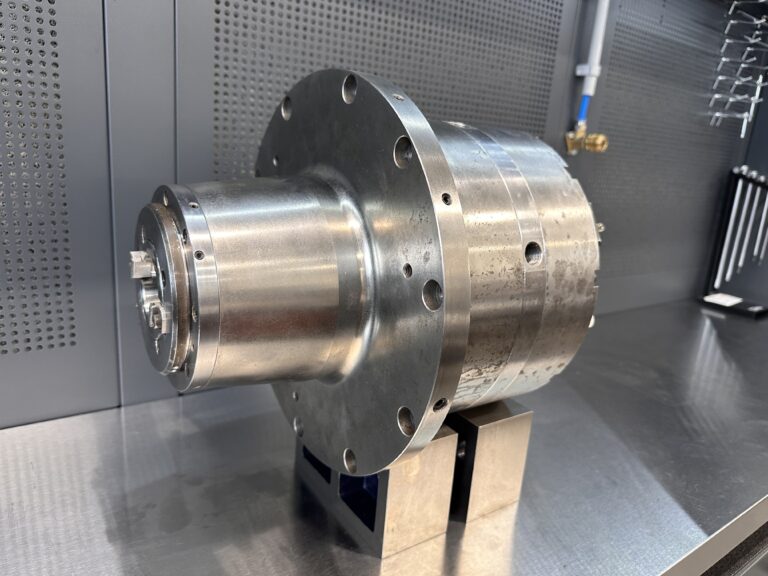

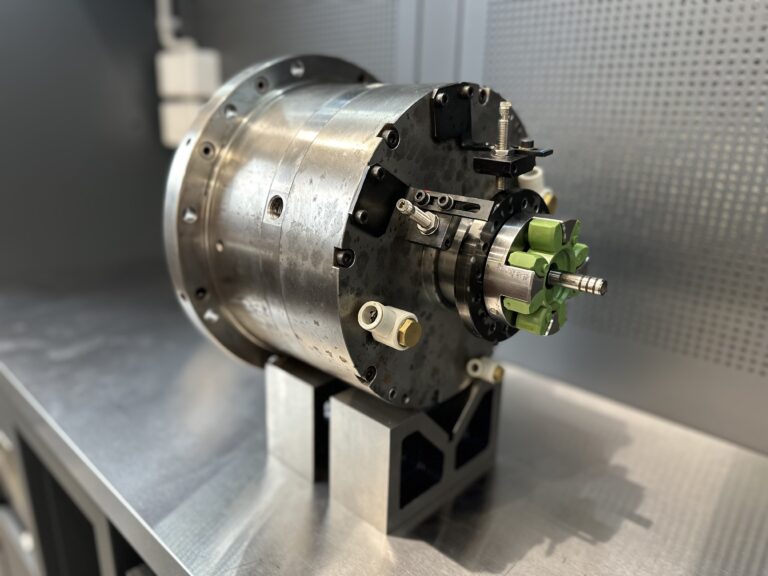

FISCHER MFW-1224/42 VC HSK-E40 electrospindle repair on SPEED HAWK 650

The FISCHER MFW-1224/42 VC HSK-E40 electrospindle operates in very demanding conditions: rotational speed up to 42,000 rpm, HSK-E40 tool interface and a high-precision SPEED HAWK 650 machining center. Under such parameters even minor wear of the bearings, taper or clamping unit quickly leads to reduced surface quality, increased vibration and shorter tool life.

Read more

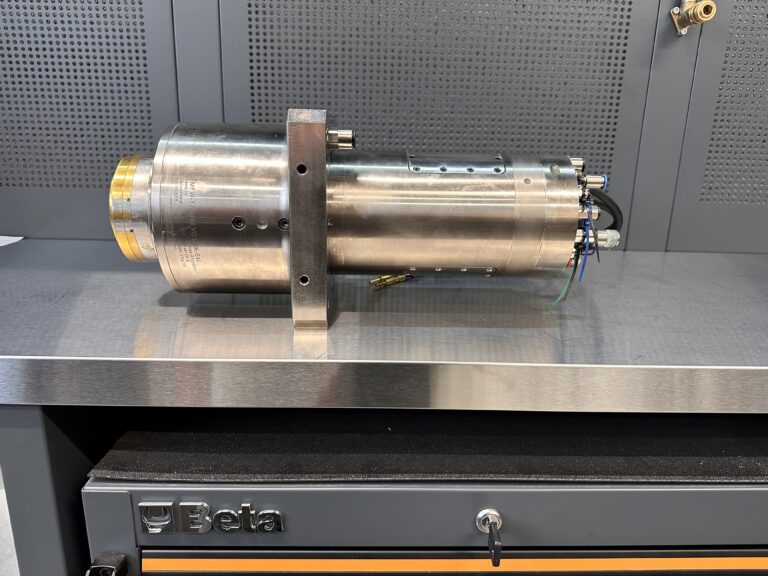

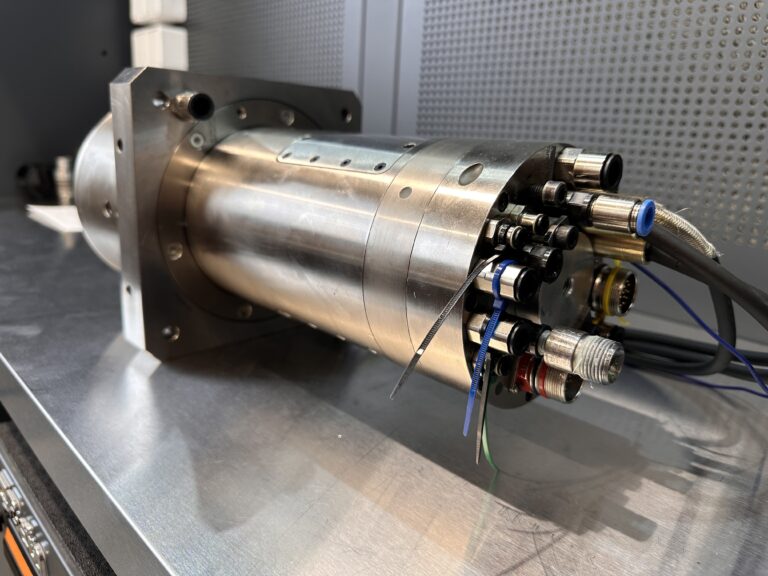

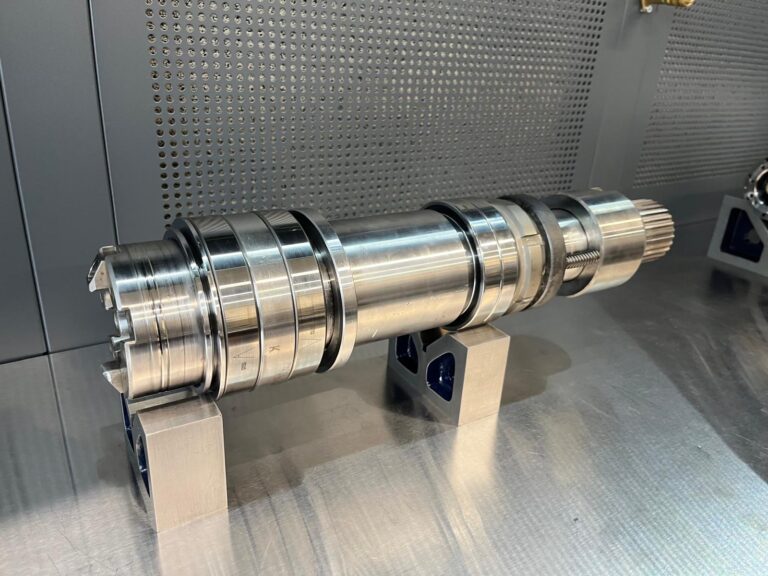

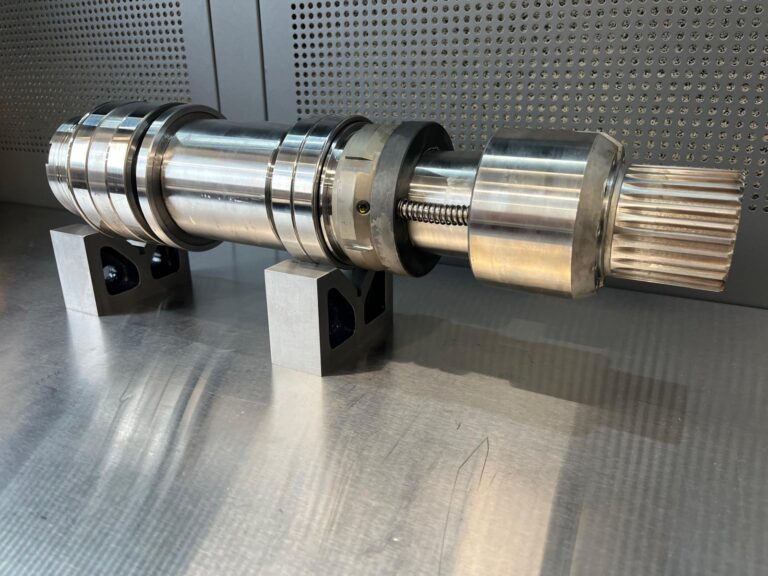

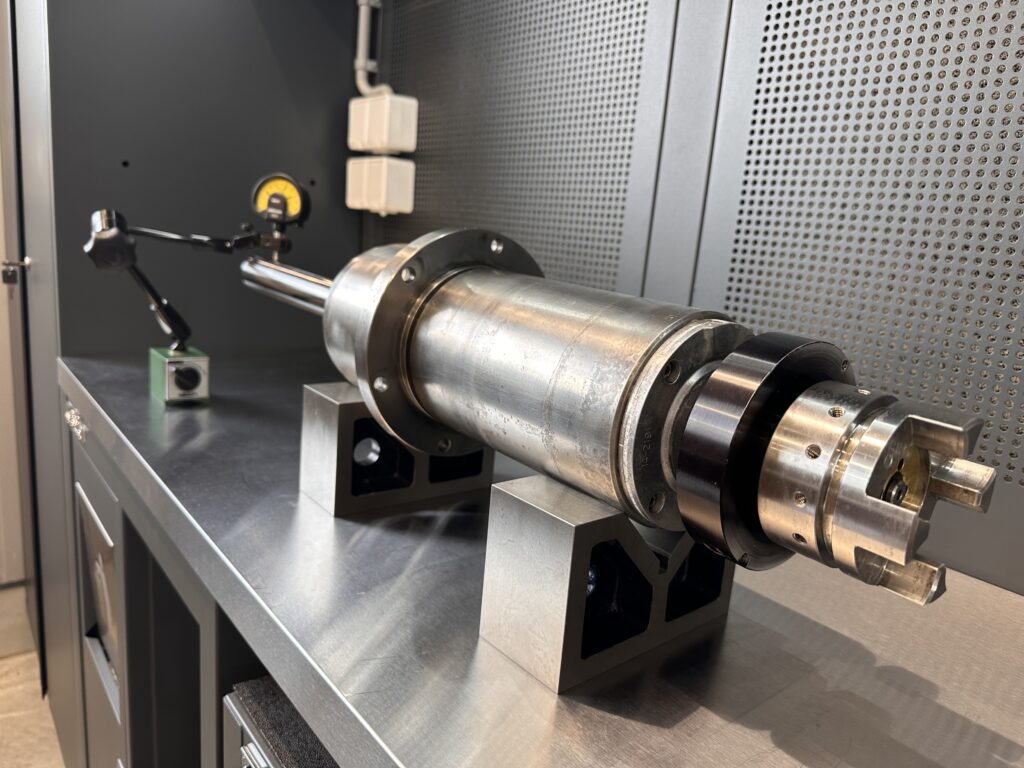

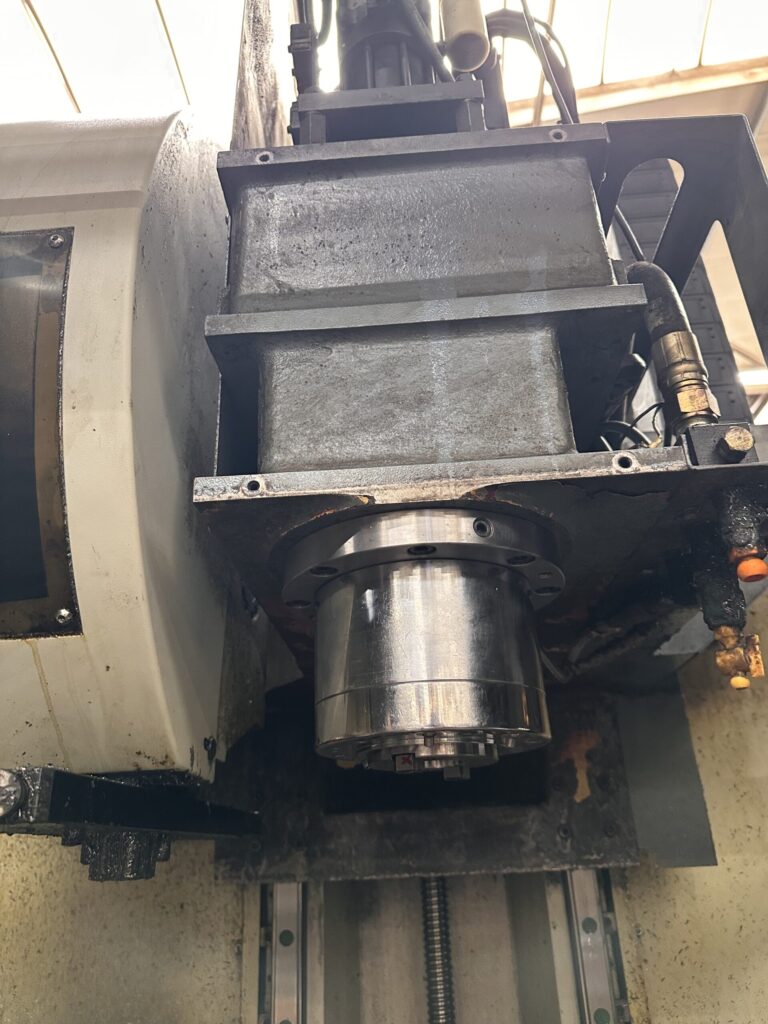

CHIRON FZ 18 W Spindle Service - Full Warranty

A spindle from the CHIRON FZ 18 W machining center arrived at our service. Two issues were reported: no tool clamping and a worn SK40 taper. This combination typically indicates wear of several components at once: the drawbar mechanism, bearings and the taper itself. We took over the entire process – from removing the spindle from the machine to reinstalling it in line with the CHIRON procedure. Thanks to this the customer has one point of contact, one report and full responsibility on our side.

Read more

Royal spindle repair on MTcut V85

A ROYAL spindle working in a MTcut V85 machining center arrived at our service. The unit with a speed of 12,000 rpm and SK40 taper failed due to bearing seizure. The spindle was immediately removed by the client’s Maintenance Department, and the entire process was supervised and instructed by BMS Spindle Service specialists.

Read more

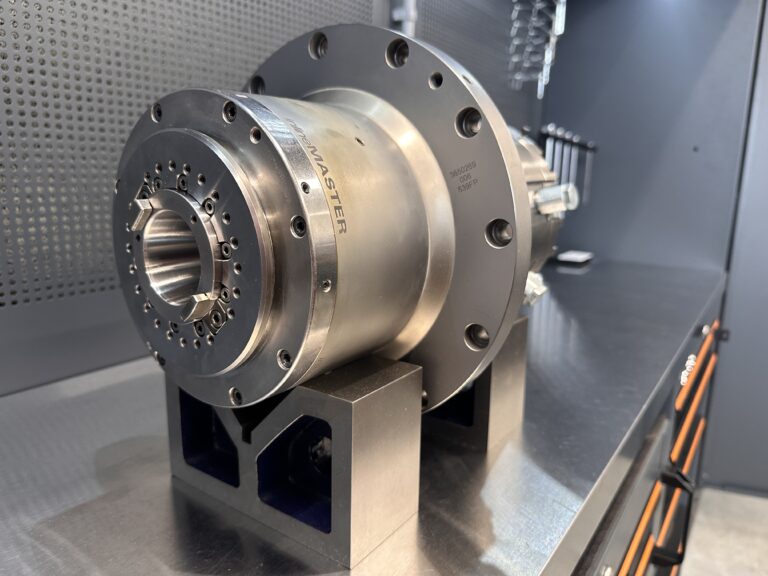

KESSLER Spindle Repair on DMG CMX 1100 V

The complete overhaul of the KESSLER spindle in our workshop restored factory precision and process stability to the DMG CMX 1100 V. We delivered a comprehensive service scope including bearing replacement, SK40 taper restoration, installation of a brand-new OEM drawbar assembly, sensor calibration, and replacement of all seals. Additionally, we supported the customer during self-installation of the spindle and helped eliminate the root cause of the previous coolant ingress. The service is covered by a 12-month warranty.

Read more

FANUM Machine Electrospindle Repair – HSD ES350L

An HSD ES350L electrospindle from a FANUM machine arrived at our service center. The unit reported increased noise and noticeable vibrations at higher speeds. These are classic symptoms of high-speed bearing wear and a weakened tool drawbar. In such cases, a rapid, precise repair is crucial because every hour of machine downtime means real production costs.

Read more

OKUMA M560 Electrospindle Repair – Complete Overhaul Process

A machining center OKUMA Genos M560 arrived at our service with spindle wear symptoms: increasing noise at high speeds, noticeable vibrations, and occasional alarms during tool changes. Our goal was to restore stable operation, repeatability, and full speed parameters. Below we present the course of the OKUMA M560 electrospindle regeneration as a completed case study.

Read more

SCM 2936230015L Spindle Repair in 4 Days

A SCM 2936230015L spindle with HSK 63F taper and up to 24 000 rpm reached our service. The customer faced an unplanned downtime, so the job was marked as urgent — the priority was to restore full functionality fast. The entire process — from pickup to return — was completed in 4 days, minimizing production losses to the absolute minimum.

Read more

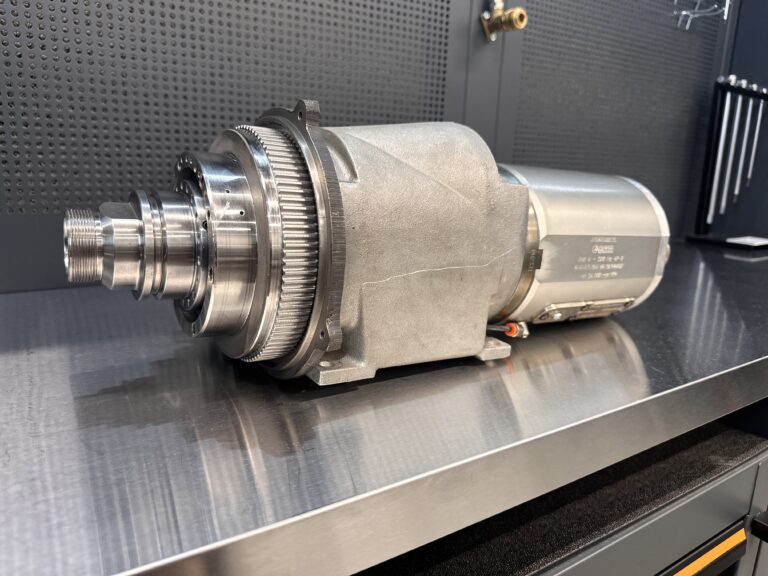

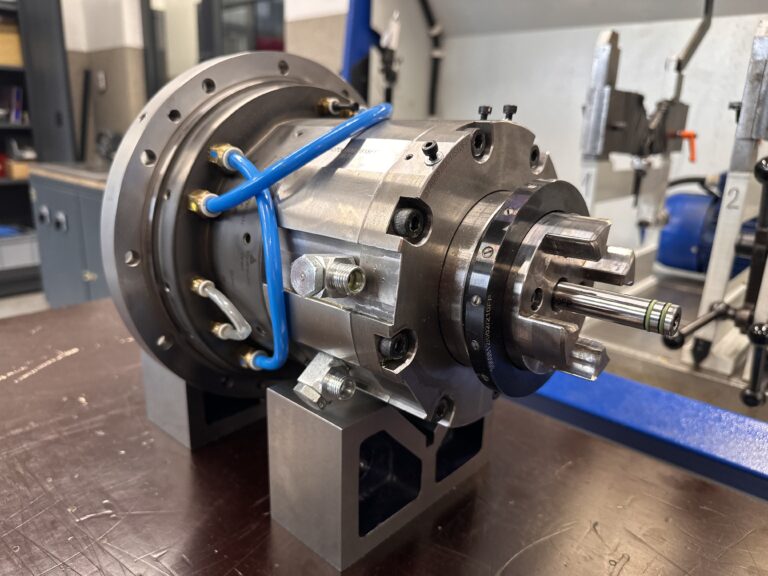

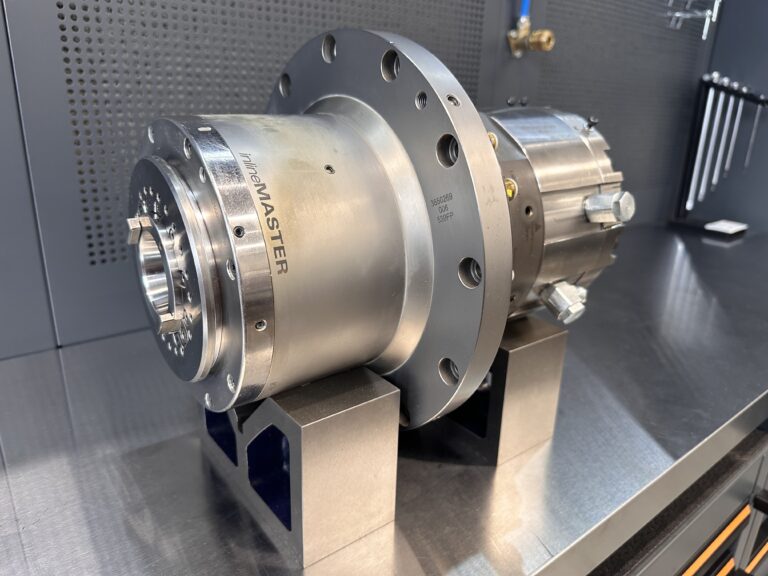

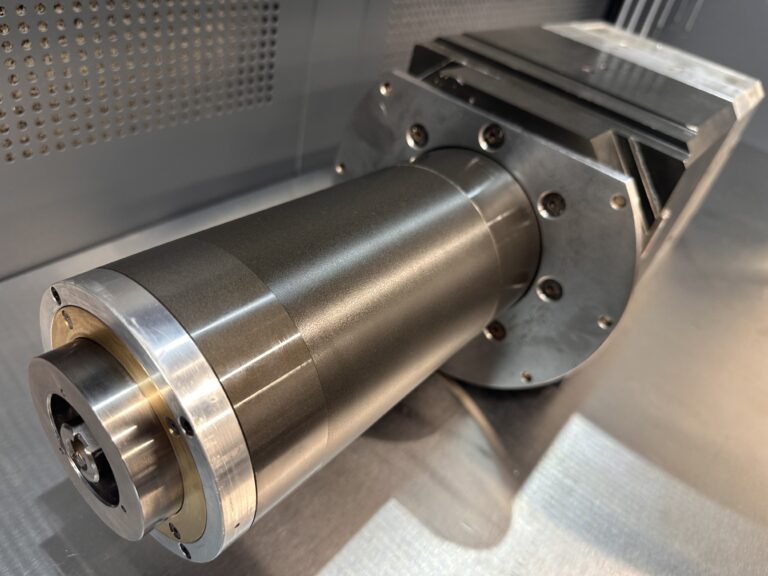

DMG MORI Spindle Repair – ISO40 Taper

A spindle from a machining center DMG MORI arrived at our service. It is a KESSLER inlineMASTER unit with an ISO40 taper and a maximum speed of 18 000 rpm. The customer reported increasing noise at higher speeds, noticeable vibration during milling and occasional problems with tool retention. After a short interview about the machine’s operation, we proceeded to full diagnostics.

Read more

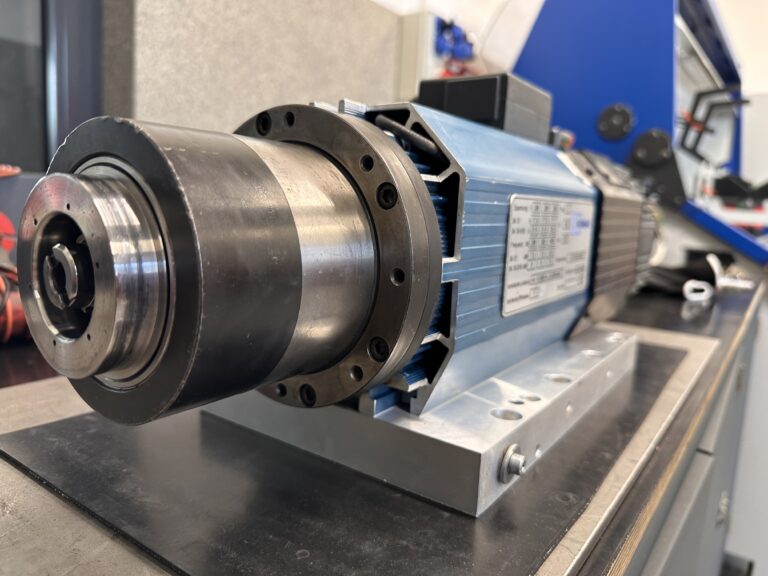

HOMAG BIZ 411 Spindle Repair – HSK 63F Taper

The scope covered a full HOMAG spindle overhaul from a BIZ 411 machine, rated for 24,000 rpm and using an HSK 63F taper. It included comprehensive diagnostics, replacement of ceramic (hybrid) bearings, precision dynamic balancing, and HSK 63F drawbar rebuild and calibration. The entire process was organized on an expedited basis — delivery and on-site installation the next day after service completion. HOMAG electrospindles are our specialty — we know their construction down to the smallest detail.

Read more

DOOSAN DNM 350/5AX Spindle Repair after Severe Collision

A DOOSAN spindle arrived for service after a severe collision with the 5-axis table. The symptoms were clear: noisy bearings and high radial runout, which prevented stable machining. In this kind of machine everything is decided at very small values — every micron countsFrom the start we agreed with the customer on a fast approach. After disassembly at the customer’s site, we collected the spindle directly, door-to-door to shorten downtime and avoid additional transport risk. The maintenance department on the customer’s side did a great job: quick decision, tidy workstation, complete incident information. Thanks to that we could get to work immediately.

Read more

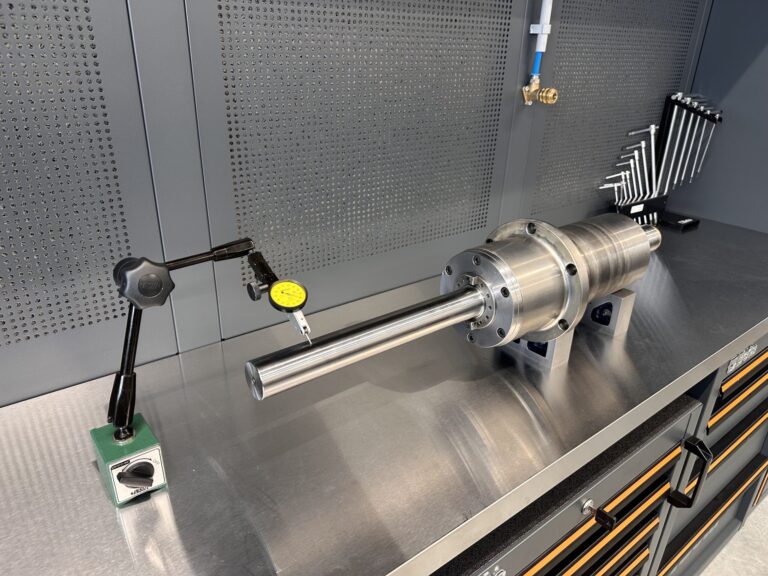

HAAS VM-2 milling machine spindle repair

The spindle in the HAAS VM-2 operates at high speeds and loads, where every micron matters for surface quality, tool life and process stability. In this job the goal was a full HAAS spindle repair with restoration of the SK40 taper geometry and achieving the lowest possible runout at an L-300 test length. After completion we confirmed runout below 2 µm on the test bar and 1–2 µm directly on the taper—values typical of a premium, like-new spindle.

Read more

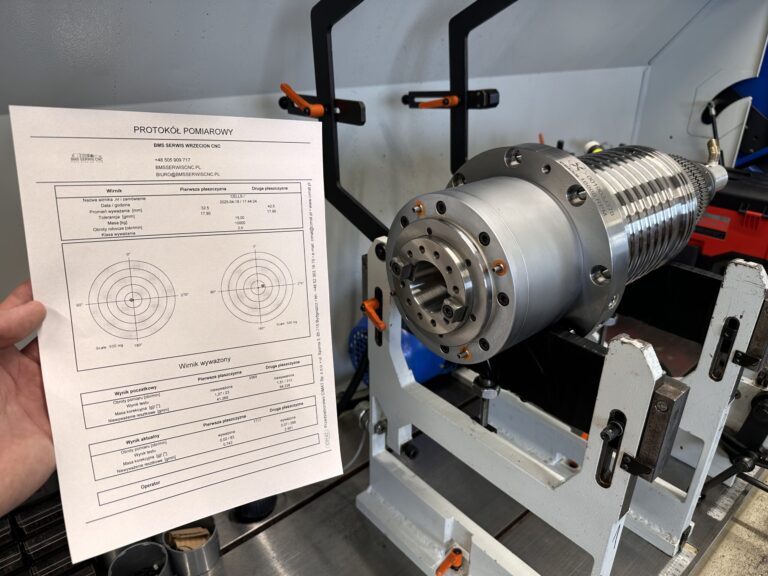

CHIRON HSK 63A spindles repair – CNC service and balancing

Two spindles from the renowned CHIRON brand, operating in machines from the same manufacturer and equipped with HSK 63A tapers, arrived at our service center. These components are crucial for maintaining the highest machining quality – responsible for transmitting torque to the tool and ensuring stability during cutting. In both cases, the customer reported clear signs of wear that negatively affected production: increased noise, noticeable vibrations and a drop in dimensional accuracy of machined parts.

Read more

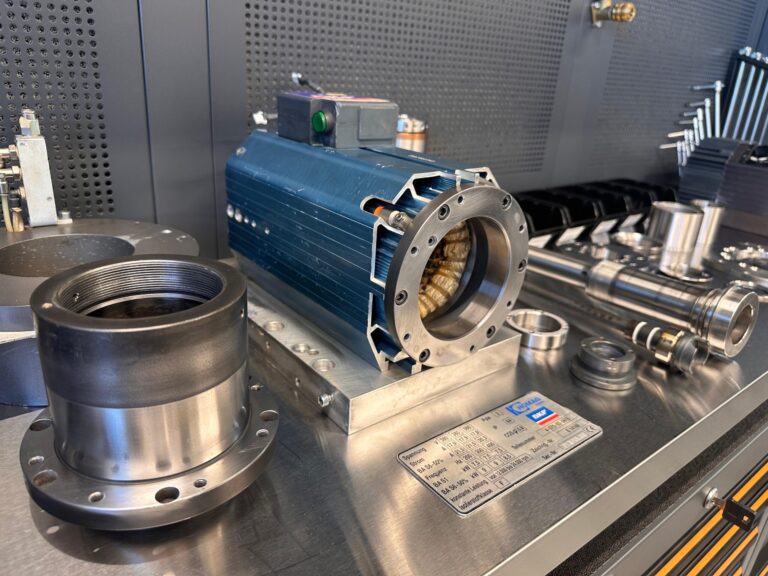

Express repair of HOMAG SKF electrospindle from Weeke Venture 1M – just 5 days!

An HOMAG SKF electrospindle, mounted in a Weeke Venture 1M CNC machine used for daily furniture production, arrived at our service center. The customer reported clear signs of spindle degradation: increased noise, noticeable vibrations, and lower machining quality. Due to a tight production schedule and high precision requirements, quick and effective action was essential.

Read more

GIORDANO COLOMBO spindle repair – ER32 thread, bearings, balancing

Two electrospindles from the renowned Italian brand GIORDANO COLOMBO arrived at our service center, equipped with ER32 threads and designed for manual tool change. Both spindles showed similar symptoms – noise during operation, noticeable vibrations, and excessive housing temperature. The nominal speed of these units is 18,000 rpm, and precise operation was essential for the machining processes they supported.

Read more

WEINIG HSK 63F spindle repair – taper restoration and bearing replacement

At our service center, we had the opportunity to restore full functionality to a WEINIG spindle that arrived with a severely damaged HSK 63F taper. The failure was so critical that it prevented tool release — the tool got jammed in the taper, and all disassembly attempts were unsuccessful.

Read more

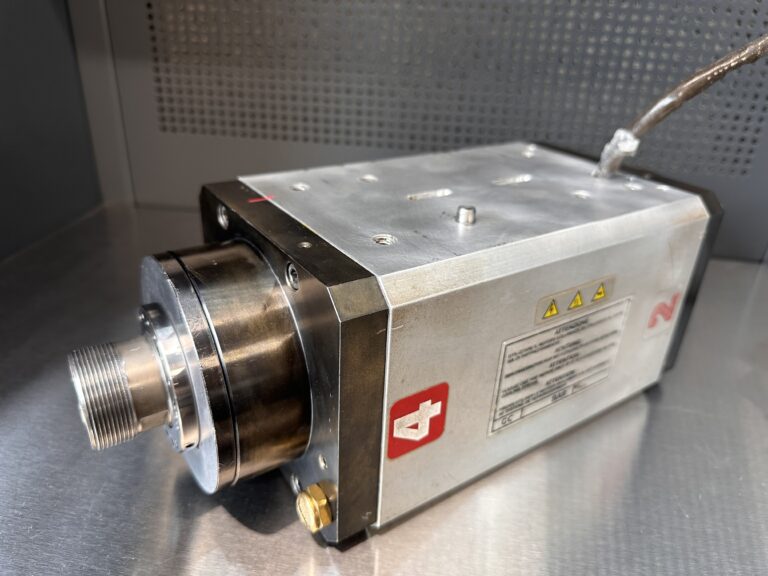

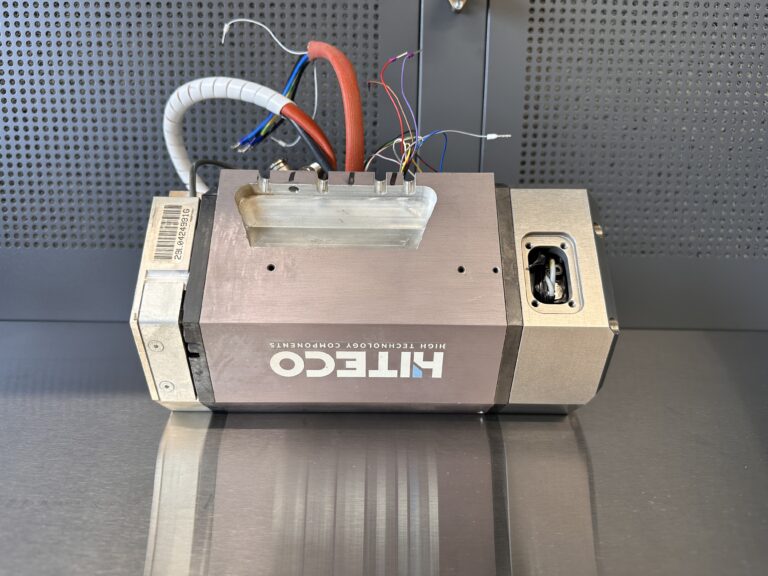

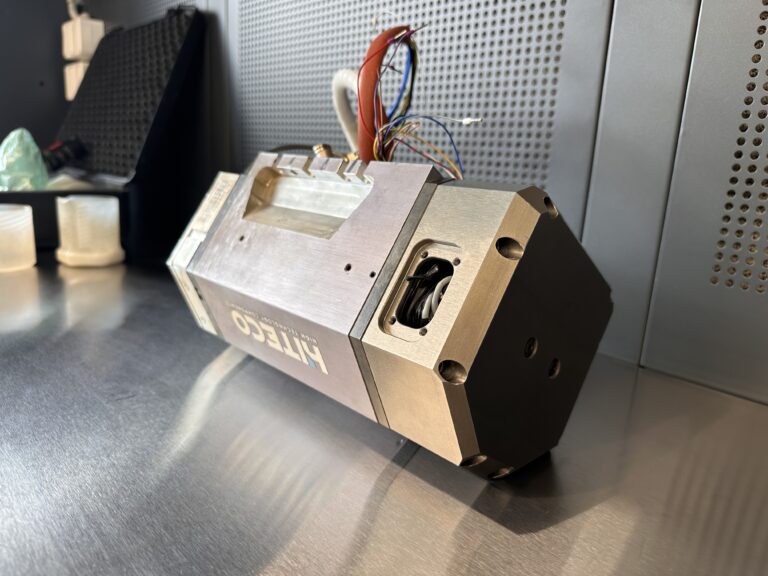

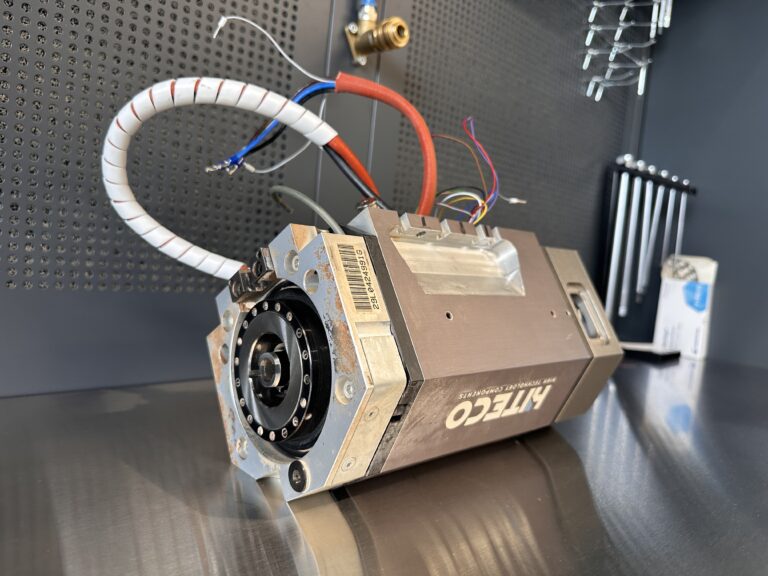

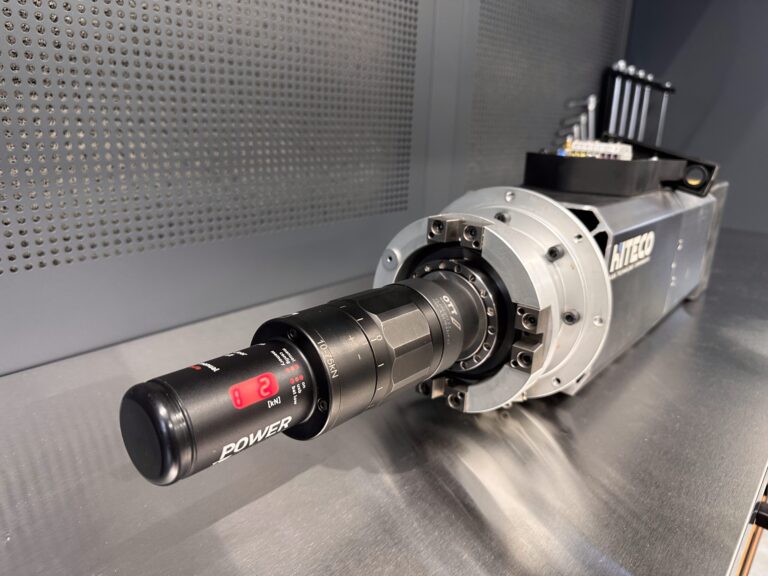

HITECO QX-2 11/12 24 63F NC Electrospindle Repair

Our service received the HITECO QX-2 11/12 24 63F NC electrospindle, used in a five-axis CNC machining center. The unit, operating at 24,000 rpm with an HSK63F taper, showed signs of instability and system communication errors that made further operation impossible.

Read more

HSD ES 959L Electrospindles Repair

Our CNC service received as many as three HSD ES 959L electrospindles designated for operation in a machining center ROVER B. Two of them were sent as damaged units, while the third one was marked by another service as "beyond repair" and intended as a donor for spare parts.

Read more

Overhaul of damaged GMN TE120sx400-61913 spindle – full service warranty

An extremely damaged GMN spindle arrived at our service center, with the SK40 taper severely worn due to prolonged use without prior servicing. The spindle underwent a full overhaul process – from disassembly and diagnostics to component repairs, followed by final testing and dynamic balancing.

Read more

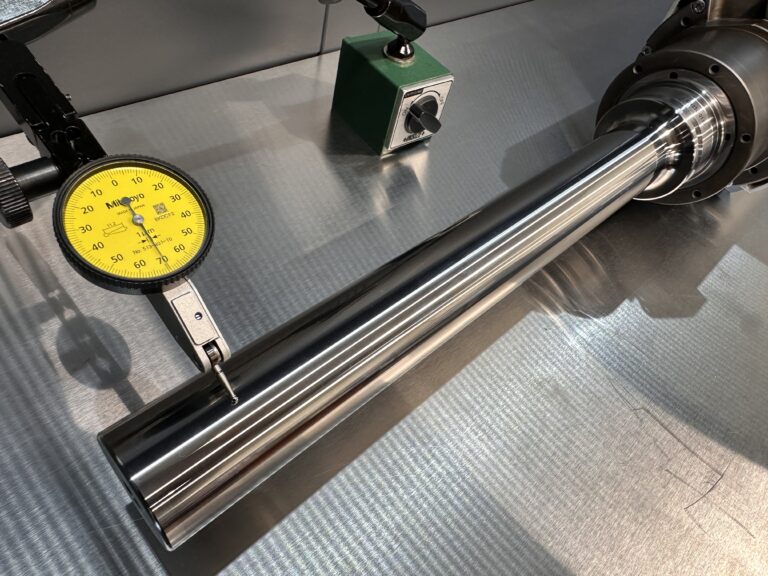

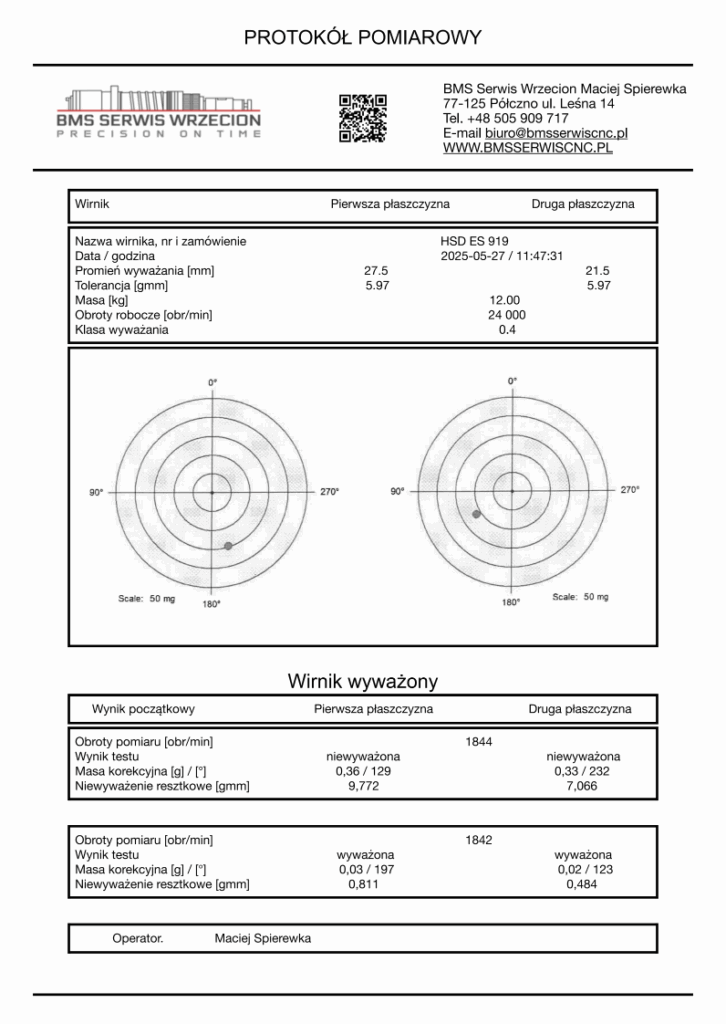

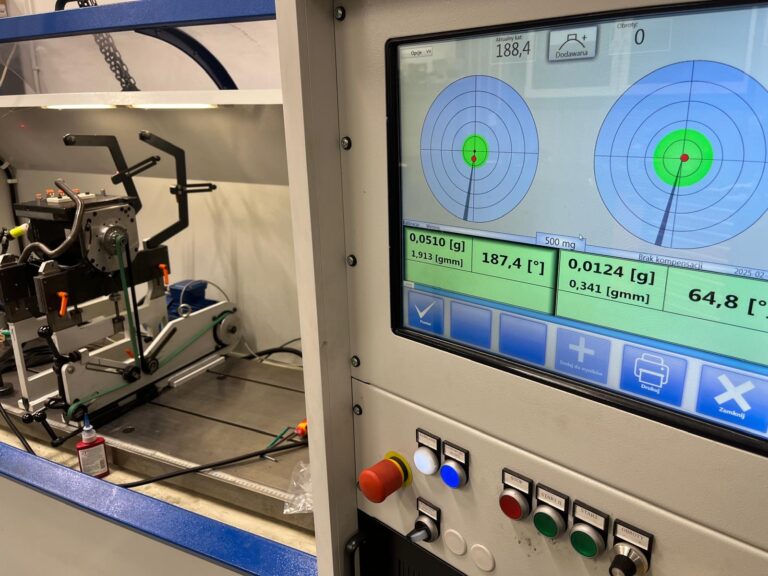

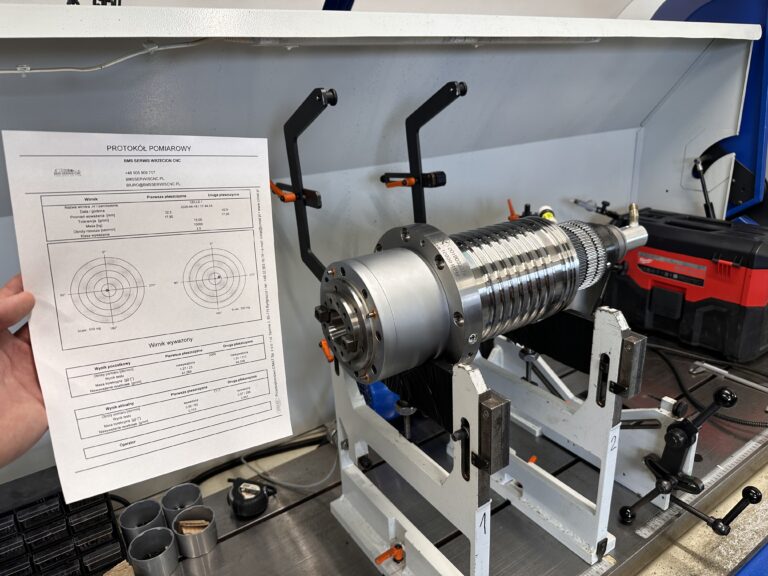

Regeneration of the HSD ES 919 electrospindle – full service in 3 days

The HSD ES 919 electrospindle was delivered to our service center with urgent need for repair due to bearing system failure and damaged sensors. The entire regeneration process, including disassembly and reassembly at the client’s site, took only 3 days. This fast turnaround was possible thanks to a pre-prepared rotating unit – a solution that minimizes machine downtime.

Read more

Safe transport of CNC spindles and electrospindles

Below we present photos taken during the loading of spindles at our facility. This is where the safe transport of CNC electrospindles to and from customers across Poland and Europe begins. Each spindle is secured according to the highest standards, ensuring complete safety on its way to repair.

Read more

HSD ES 779L Spindle Repair – Complete CNC Service

The HSD ES 779L electrospindle, operating in a 5-axis FANUM machining center, was delivered to our service. The order included a full service package: from rapid disassembly to repair, reassembly, and thermal analysis. We carried out the service door to door, ensuring maximum convenience and time savings for the client.

Read more

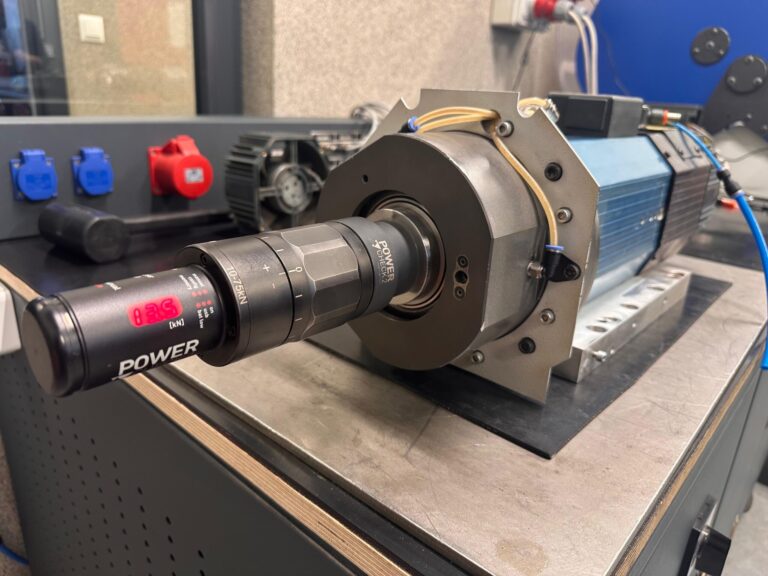

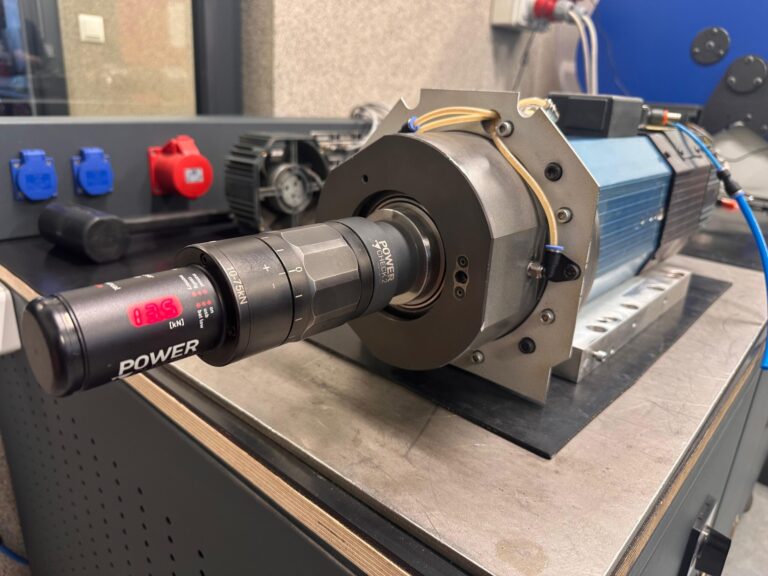

Spindle and electrospindle balancing – the key to precision and longevity

In the world of CNC machining, precision and reliability are crucial. One of the most important – and often underestimated – elements of keeping a spindle in excellent condition is dynamic balancing. Whether we are dealing with a classic spindle or an electrospindle, balancing affects the accuracy, durability, and safety of the entire machine's operation.

Read more

DOOSAN lathe spindle repair

After receiving the spindle, we began disassembly and cleaning of all components. Each part was cleaned in ultrasonic and mechanical baths, which allowed us to carry out precise geometric measurements and damage diagnostics.

Read more

SUNMIL milling machine spindle repair

The ROYAL spindle from a SUNMIL milling machine was delivered to our service center. The order included full support – from spindle disassembly at the customer's site, through complete repair, to reinstallation and machine commissioning.

Read more

Professionalism confirmed by certifications – discover our competencies

In the world of CNC spindle service, there is no room for compromise. Precision, experience, and cutting-edge technological knowledge are the pillars of our work. That’s why we constantly invest in development by participating in specialized training and workshops to ensure the highest level of service for our clients. Discover the certificates that prove our expertise!

Read more

CELLS / ROYAL SK40 Spindle Repair

A CELLS / ROYAL electrospindle with a standard SK40 taper, used in an industrial milling machine, was delivered to our service center. The condition of the unit indicated many years of operation — the spindle was heavily contaminated, and the mechanical components required a thorough inspection and overhaul.

Read more

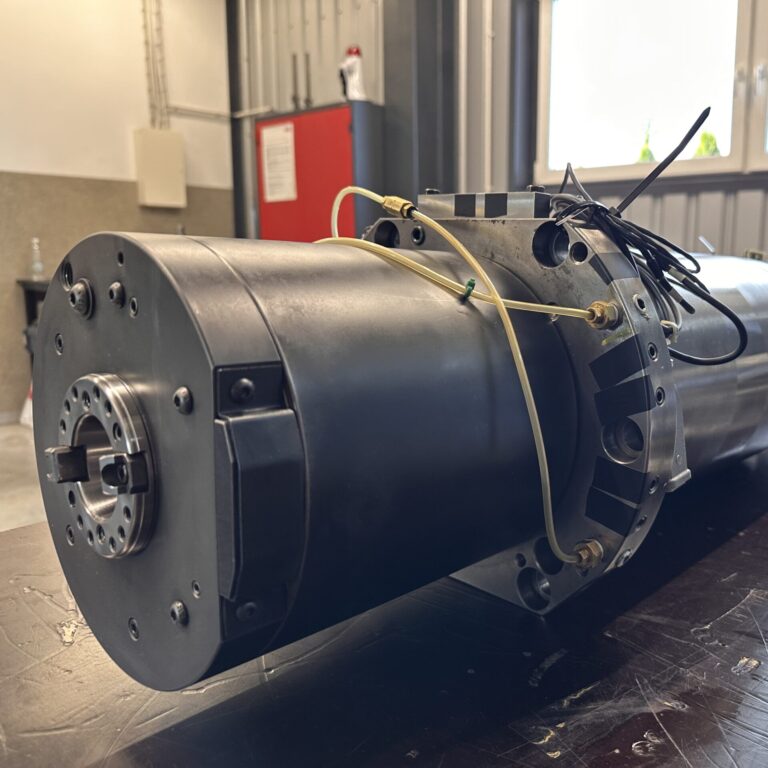

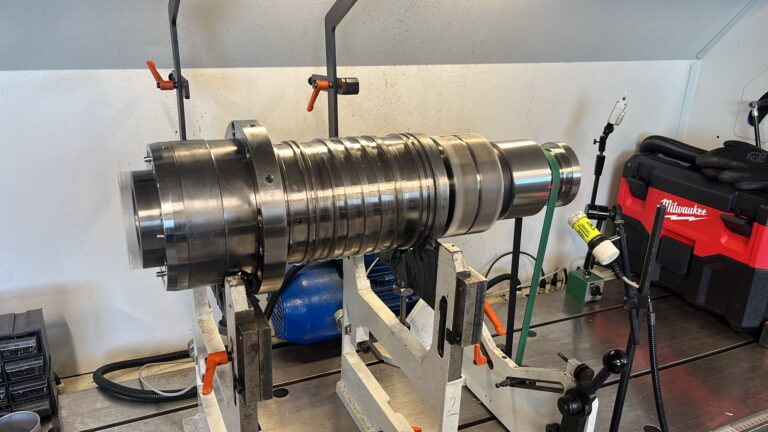

Large-Scale Spindle Repair EMAG

Two EMAG electrospindles were delivered to our service center. Despite differences in size — one weighed 2 tons, the other 1.8 tons — both required the same high level of technological expertise.

Read more

Mazak Nexus 510C-II Spindle Repair

Neglecting the early signs of spindle wear can lead to very costly consequences. One of our clients experienced this firsthand when they contacted us with a spindle issue in a MAZAK NEXUS 510C-II machining center. If you want to avoid similar problems, read on to see the full spindle repair process and what caused the serious failure.

Read more

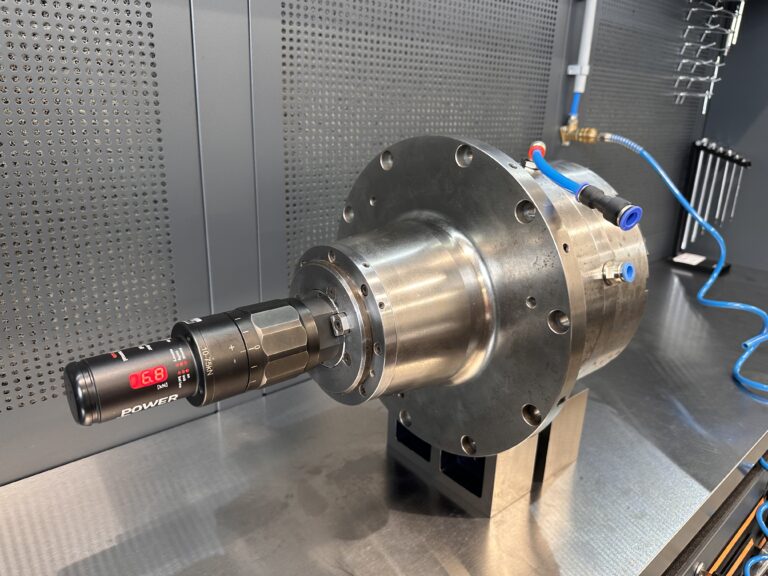

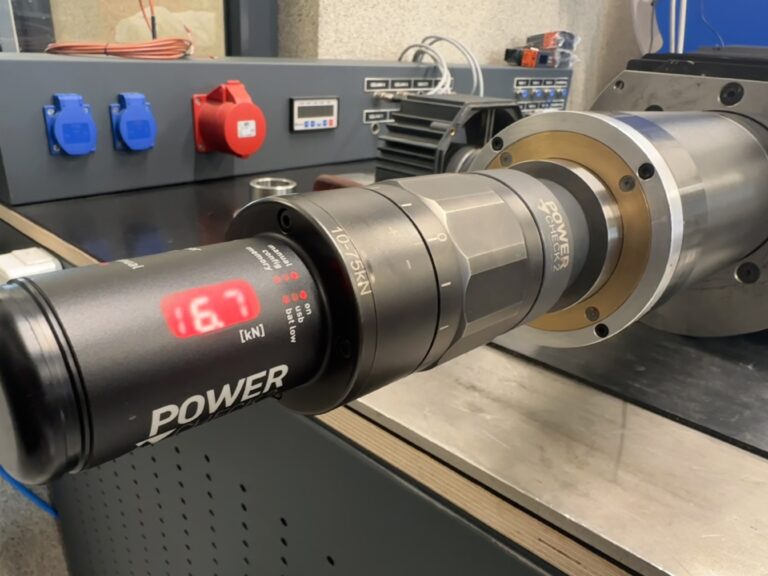

Why are regular spindle inspections so important?

Many CNC machine operators and production managers underestimate the importance of regular technical inspections of spindles and electrospindles. One of the most critical parameters that should and can be checked regularly is the tool clamping force in HSK and SK tapers.

Read more

Powermat 1500 WEINIG Spindle Repair

At our service center, we carried out a comprehensive repair of a WEING spindle from a WEING Powermat 1500 planer, which arrived in exceptionally poor technical condition. Below, we present the details of the work performed.

Read more

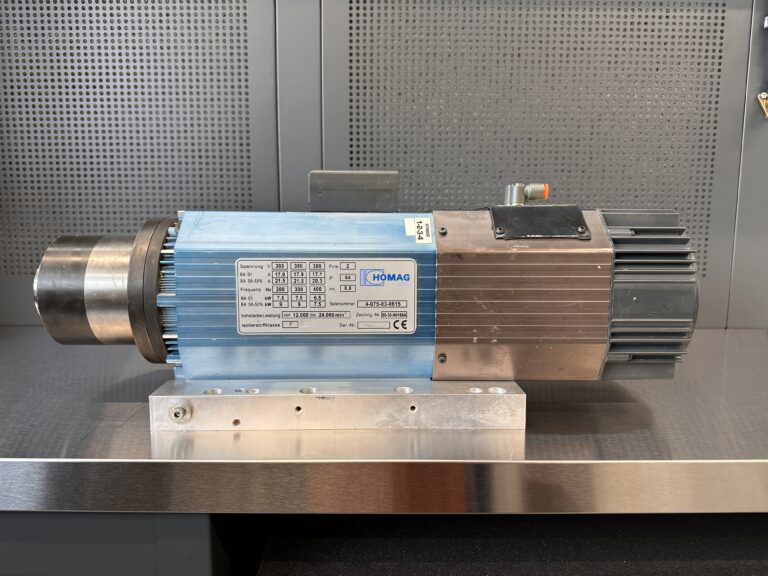

HOMAG / SKF 4-075-03-0615 Electrospindle Repair

The electrospindle was collected directly from the customer, located approximately 200 km from our service center. On the same day, we carried out a damage analysis and identified severe damage to the HSK taper gripper arms, as well as significant vibrations and loud operation of the rear bearings.

Read more

HAAS Spindle Repair SK40

The HAAS spindle arrived at our service center with bearing damage caused by a collision. Upon delivery, we performed a thorough diagnostic check and — within 4 hours — prepared a detailed repair quote.

Read more

HITECO QE-1F 12/12 24 63F NC CB Spindle Repair

We received a HITECO QE-1F 12/12 24 63F NC CB electrospindle for urgent repair. The HSK tool holder was damaged due to a collision. The main issue was a broken and cracked HSK gripper arm, which prevented the machine from continuing operation.

Read more

KENTURN KC1508H Spindle Repair

Repairing the KENTURN KC1508H spindle is a key process aimed at restoring its full operational performance. As part of our comprehensive service, we handle disassembly, repair, and reinstallation of the spindle into the customer’s machine. Each stage is carried out in accordance with the highest precision standards, ensuring long-lasting durability and reliable spindle performance.

Read more

HEIAN 7.5kW Spindle Repair

HEIAN spindle repair is a key process in restoring full functionality of CNC machining center spindles. Due to intensive use, components such as bearings and tool tapers wear out over time, affecting the precision and efficiency of the machine. At our service center, we specialize in comprehensive HEIAN spindle repair, restoring full performance in a short turnaround time. Below we present the main stages of the HEIAN spindle repair process.

Read more