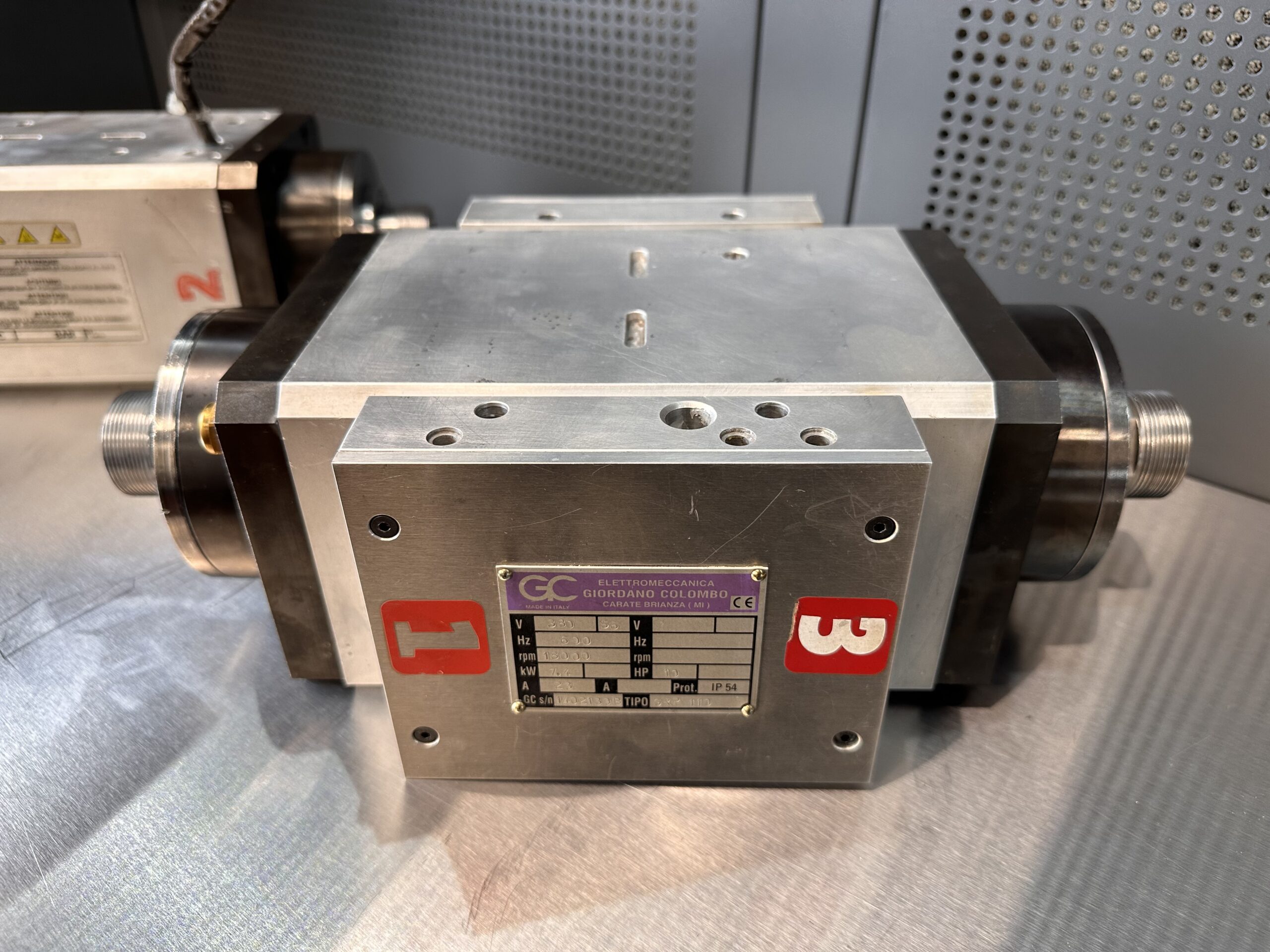

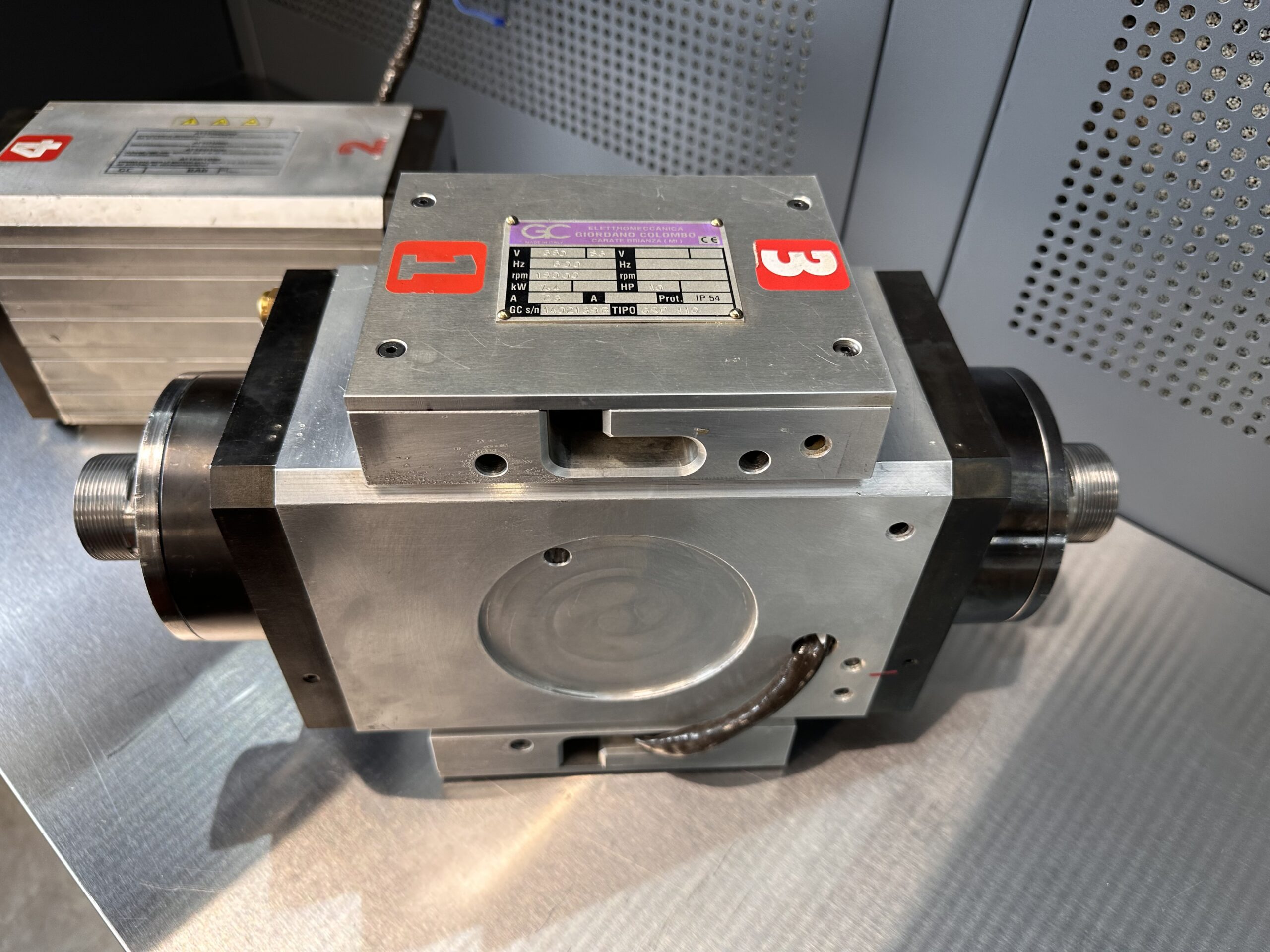

GIORDANO COLOMBO spindle repair – ER32 thread, bearings, balancing

Repair of two GIORDANO COLOMBO electrospindles – ER32 thread regeneration, bearing replacement, and 0.4G balancing

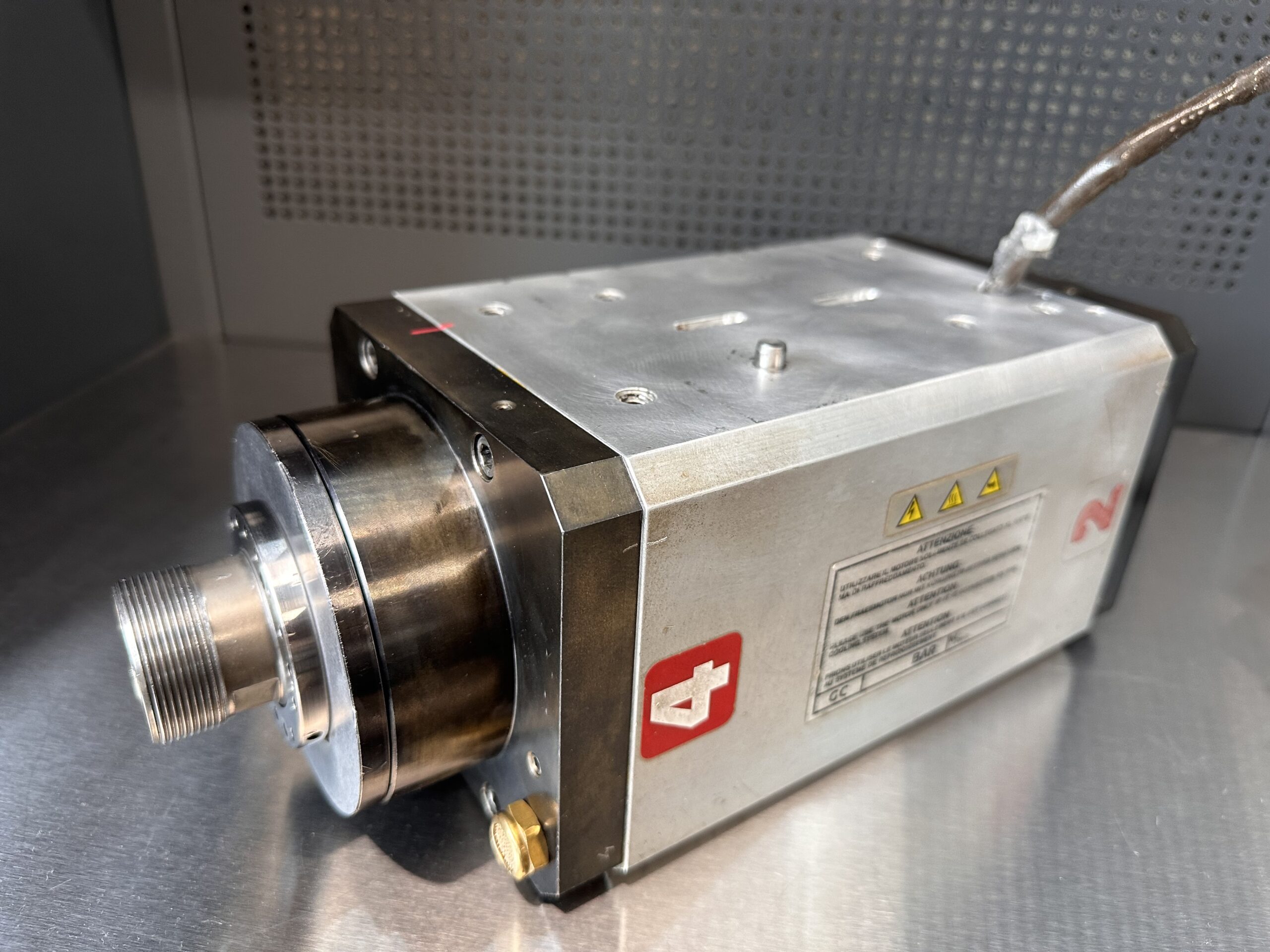

Two electrospindles from the renowned Italian brand GIORDANO COLOMBO arrived at our service center, equipped with ER32 threads and designed for manual tool change. Both spindles showed similar symptoms – noise during operation, noticeable vibrations, and excessive housing temperature. The nominal speed of these units is 18,000 rpm, and precise operation was essential for the machining processes they supported.

Initial diagnostics revealed wear of precision bearings, rotor imbalance, and damage to the ER32 taper threads. We undertook a comprehensive regeneration of both units simultaneously, following identical procedures, parameters, and quality standards.

-

Manufacturer: GIORDANO COLOMBO

-

Thread: ER32

-

Rotational speed: 18,000 rpm

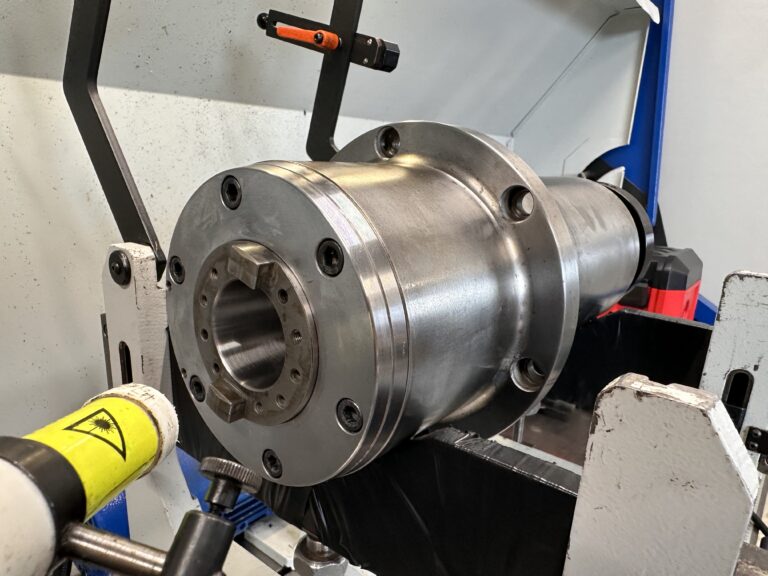

Thread regeneration

of ER32 tapers

ER32 threads are a commonly used solution in electrospindles with manual tool change. They enable quick and secure clamping of collet chucks, but with intensive use or improper installation, they can become worn or damaged.

In the case of GIORDANO COLOMBO spindles, we applied a specialized thread regeneration procedure, which included:

- thorough cleaning and inspection of the damaged surfaces,

- precision drilling and preparation for a new threaded insert,

- installation of a repair sleeve compliant with ER32 standard,

- testing the tightening torque and tool alignment accuracy.

Thanks to this procedure, full functionality of the tool interface was restored and the thread’s durability was significantly extended.

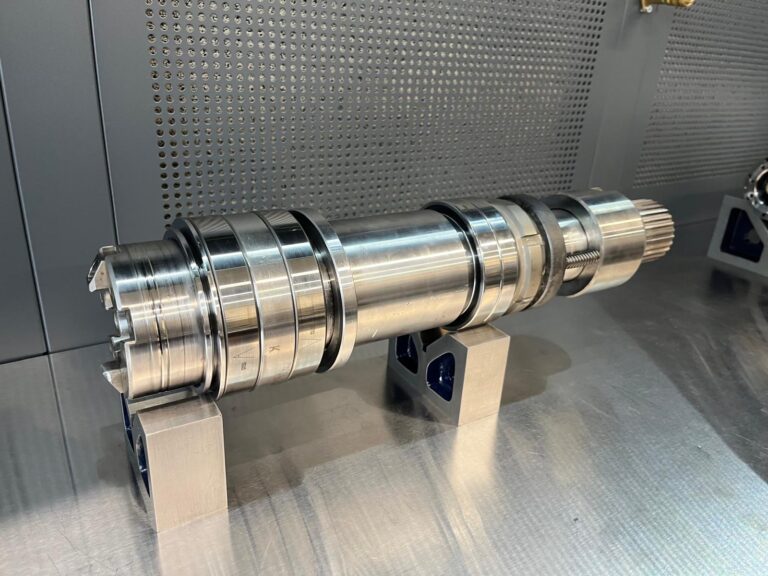

Replacement of

precision spindle bearings

Both electrospindles were disassembled, cleaned, and thoroughly inspected to assess the condition of internal components. The existing bearings showed signs of wear – including traces of seizure and discoloration from overheating.

The replacement was carried out according to the following procedure:

After the replacement, both spindles underwent several hours of run-in and load testing. As a result, the customer received two components fully ready for precision operation.

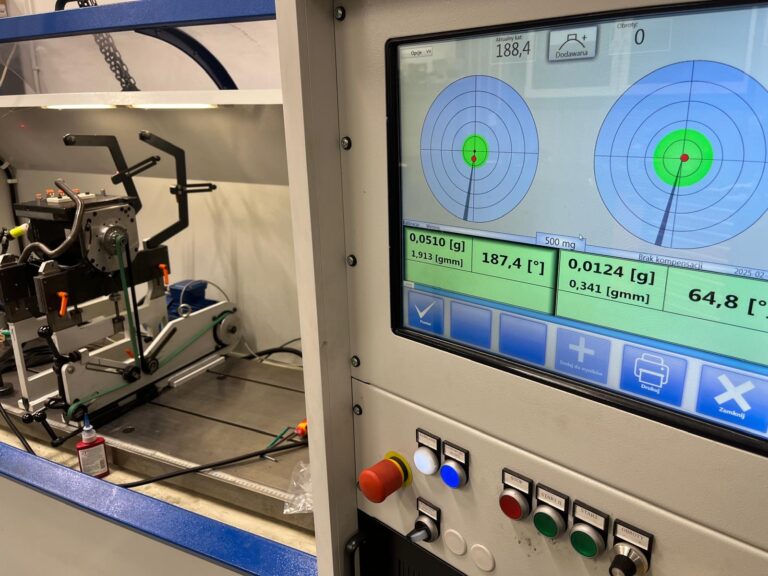

Electrospindle balancing

at 0.4G accuracy class

One of the key stages of the entire regeneration process was the dynamic balancing of the spindles, carried out on a specialized balancing machine that allows achieving an accuracy class of 0.4G. This parameter is beyond the capabilities of standard industrial services – matching or exceeding OEM level.

The balancing process included:

- Calibration of vibration sensors and setting the axis of rotation,

- mass correction on the rotor by drilling or adding special weights,

- final measurements and generation of the balancing protocol.

The result? Significant vibration reduction, lower noise levels, and less bearing stress during operation – all of which translate into longer spindle lifespan.

GIORDANO COLOMBO brand

Italian precision and innovation

GIORDANO COLOMBO is an Italian electrospindle manufacturer that has been supplying components for advanced CNC machines for decades. The spindles of this brand are known for:

- high reliability,

- excellent power-to-weight ratio,

- ability to operate at very high rotational speeds,

- a wide range of models – from air-cooled units to liquid-cooled electrospindles for continuous operation.

Regenerating such units requires not only experience, but also access to top-quality components and equipment capable of restoring or even exceeding original specifications.

Summary

The dual-spindle repair of GIORDANO COLOMBO is another example of the comprehensive service we provide. The customer received not only fully functional and balanced spindles, but also detailed documentation of the work performed, measurement protocols, and technical support.

The procedures used comply with the highest industry standards.