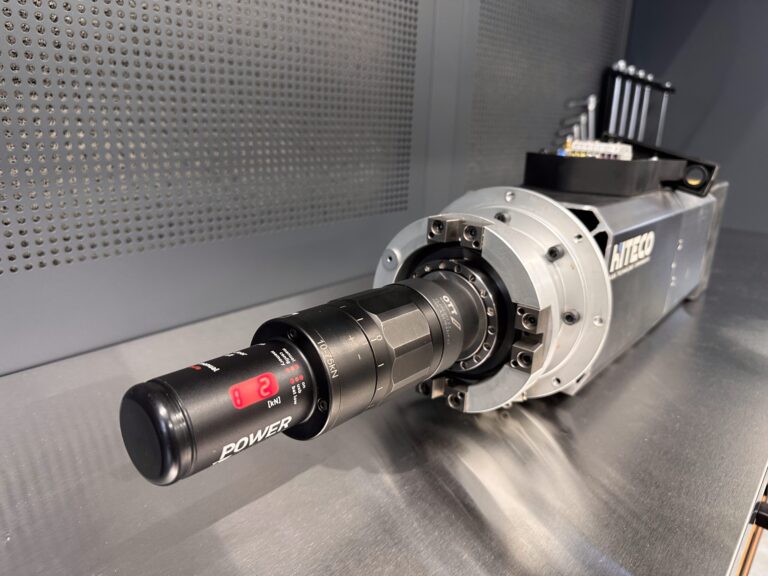

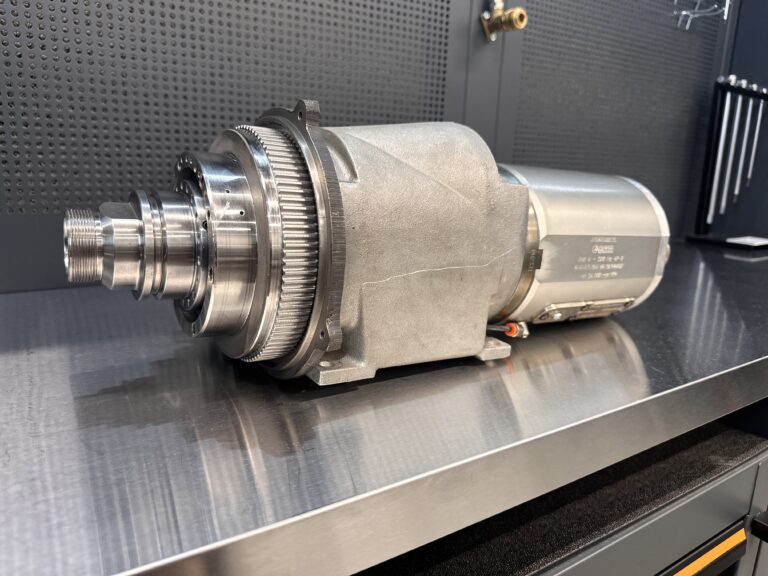

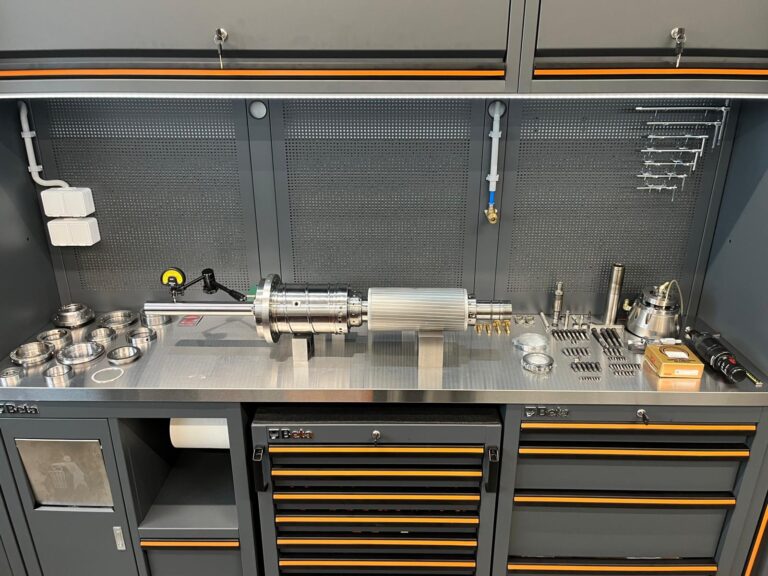

OKUMA M560 Electrospindle Repair – Complete Overhaul Process

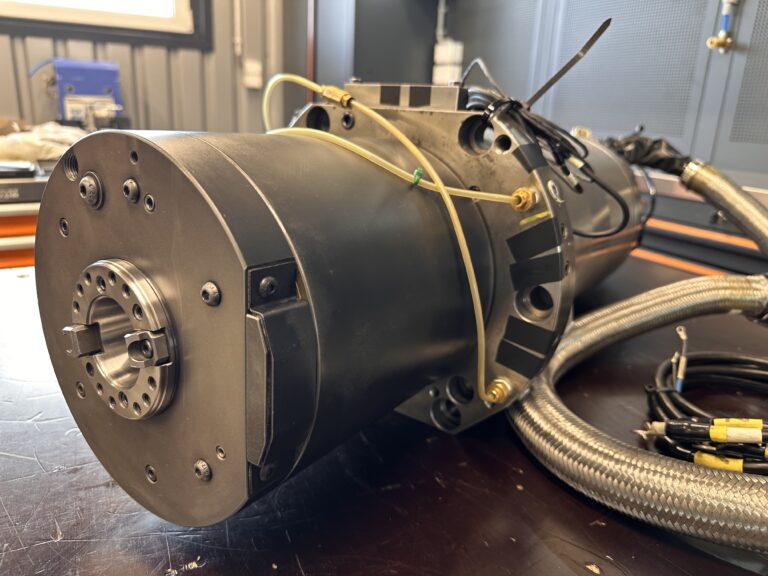

A machining center OKUMA Genos M560 arrived at our service with spindle wear symptoms: increasing noise at high speeds, noticeable vibrations, and occasional alarms during tool changes. Our goal was to restore stable operation, repeatability, and full speed parameters. Below we present the course of the OKUMA M560 electrospindle regeneration as a completed case study.

Spindle specification:

-

Manufacturer: OKUMA

-

Machine model: OKUMA Genos M560

-

Tool taper: SK40

-

Max speed: 15 000 rpm

Cause of the problem

noise, vibrations

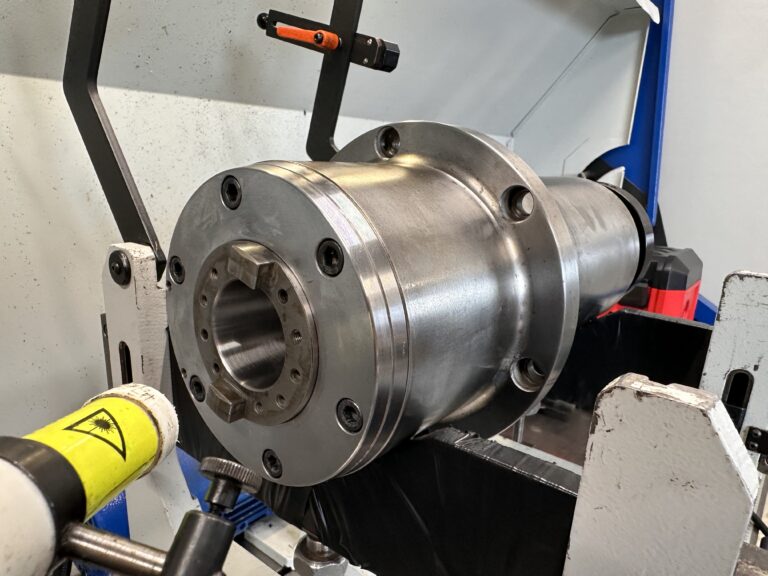

We began by safely removing the spindle from the machine and performing an initial diagnosis. We measured runout on a test holder, checked operating temperatures and seal condition. We recorded baseline data for comparison with post-service results. The assessment confirmed bearing wear, marks on the SK40 taper, and reduced clamping force.

Scope of work performed

during the OKUMA M560 electrospindle refurbishment

We carried out the process comprehensively, in line with our service standard:

Precision

of the highest class

The effect after installation in the machine was clear. The spindle ran quieter and smoother, temperature stabilized faster, and vibrations dropped to a level that did not affect surface quality or tool life. Tool change issues disappeared and no unplanned alarms occurred. Operators reported improved roughness and dimensional repeatability on parts produced on the OKUMA Genos M560.

After completion, we provided operating recommendations. The customer performed a short spindle run-in—gradually increasing speed while monitoring temperature—and implemented a simple inspection schedule. We recommended regular cleaning of SK40 holders and periodic clamping-force checks to keep the effect of the OKUMA M560 electrospindle repair as long as possible.

Why it’s worth performing

OKUMA M560 electrospindle refurbishment

- Lower cost compared to a new unit

- Fast turnaround and parts availability

- Guaranteed precision and operational safety

- Balancing, clamping calibration, and a final report

Trust our experience

choose CNC spindle specialists

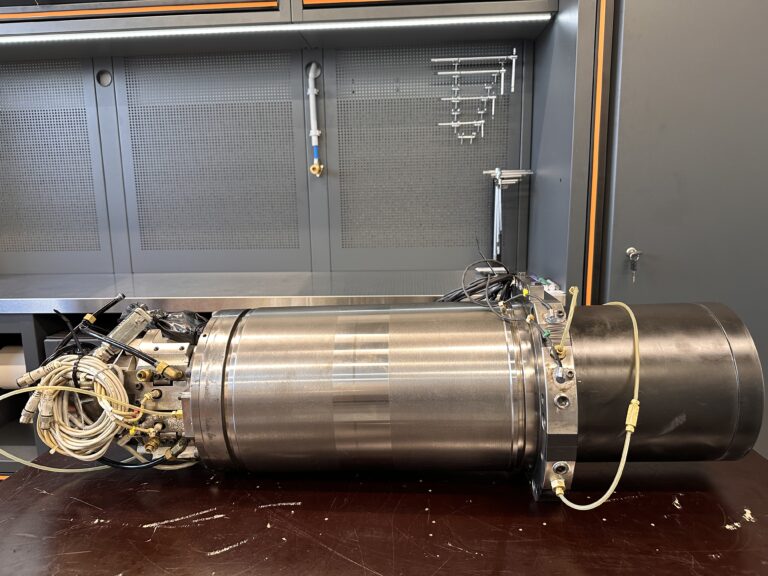

In summary: we performed a complete OKUMA M560 electrospindle refurbishment—from disassembly, cleaning, bearing replacement, and taper restoration to clamping calibration, balancing, and final tests. This OKUMA M560 electrospindle service restored machine stability and production repeatability and peace of mind.

After completion, the OKUMA M560 electrospindle was packed and secured for shipment in a special transport crate, with documentation and test report attached.

If you notice similar symptoms (noise, vibrations, heating, ATC alarms), this path is the fastest way to safely return to parameters.