DOOSAN DNM 350/5AX Spindle Repair after Severe Collision

DOOSAN DNM 350/5AX Spindle Repair

-

Machine: 5-axis machining center DOOSAN DNM 350/5AX

-

Spindle: DOOSAN / FANUC

-

Speed: 15 000 rpm

-

Taper: BT40

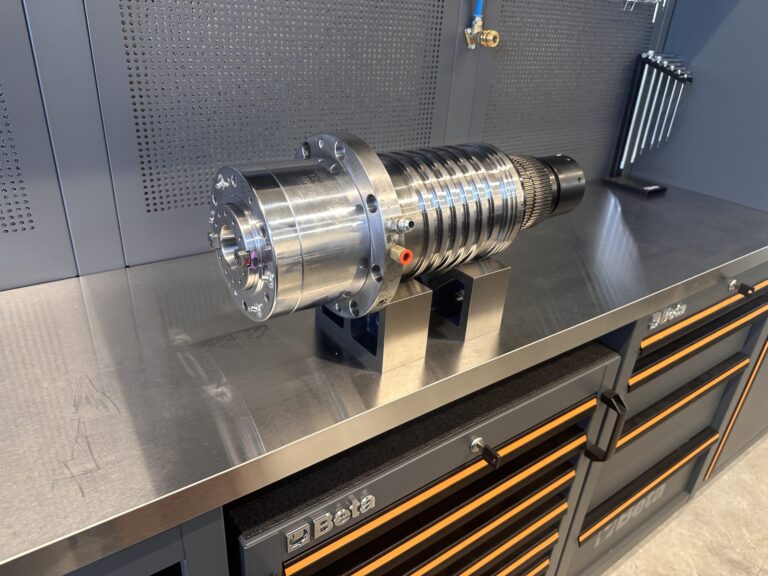

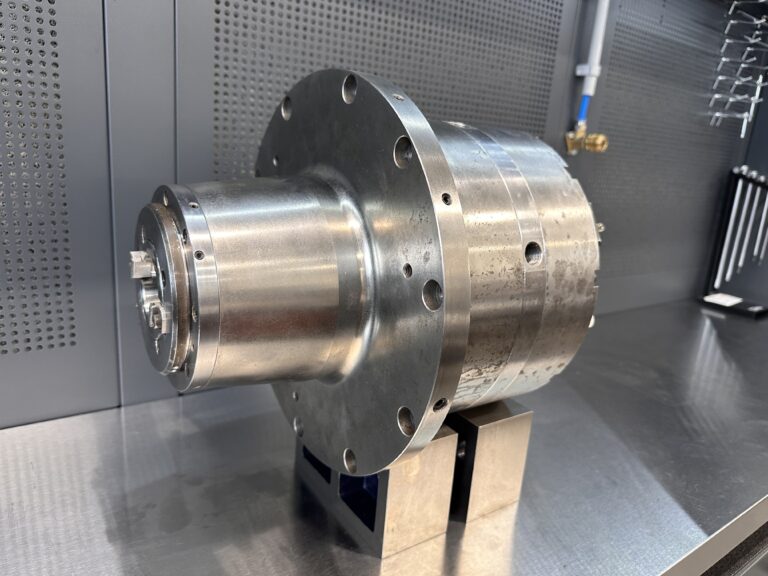

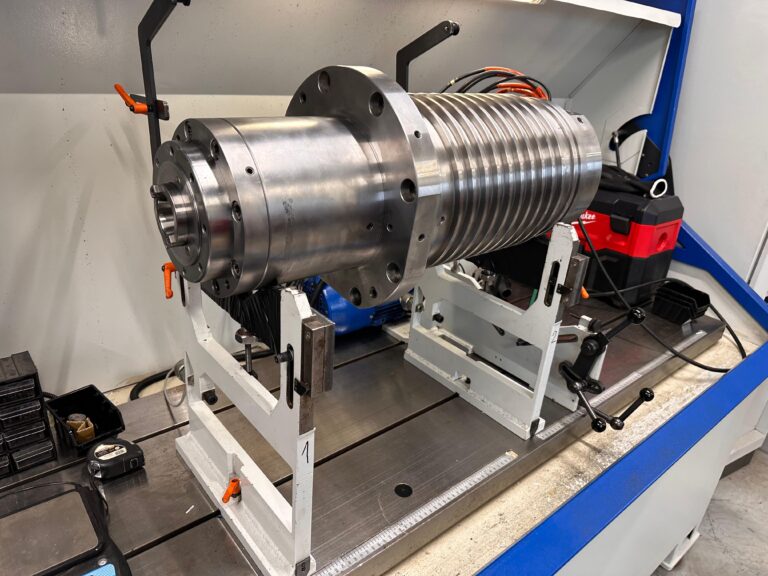

A DOOSAN spindle arrived for service after a severe collision with the 5-axis table. The symptoms were clear: noisy bearings and high radial runout, which prevented stable machining. In this kind of machine everything is decided at very small values — every micron counts

From the start we agreed with the customer on a fast approach. After disassembly at the customer’s site, we collected the spindle directly, door-to-door to shorten downtime and avoid additional transport risk. The maintenance department on the customer’s side did a great job: quick decision, tidy workstation, complete incident information. Thanks to that we could get to work immediately.

Why this repair

of the DOOSAN DNM 350/5AX spindle mattered

In 5-axis machining, even small spindle runout transfers to the tool and then to the part. You get vibrations, poorer surface finish, shorter tool life and repeatability issues.

At 15 000 rpm every deviation grows with speed, so precise repair is essential. In this case the spindle arrived straight after disassembly — freshly delivered from the customer to our service facility and secured for unloading and initial inspection.

After this direct delivery from the customer to the service, our goal was simple: restore quiet operation, stability and repeatability and prepare the spindle for re-installation, so the machine would again hold micron-level tolerances.

How the spindle repair looked

DOOSAN DNM 350/5AX — step by step

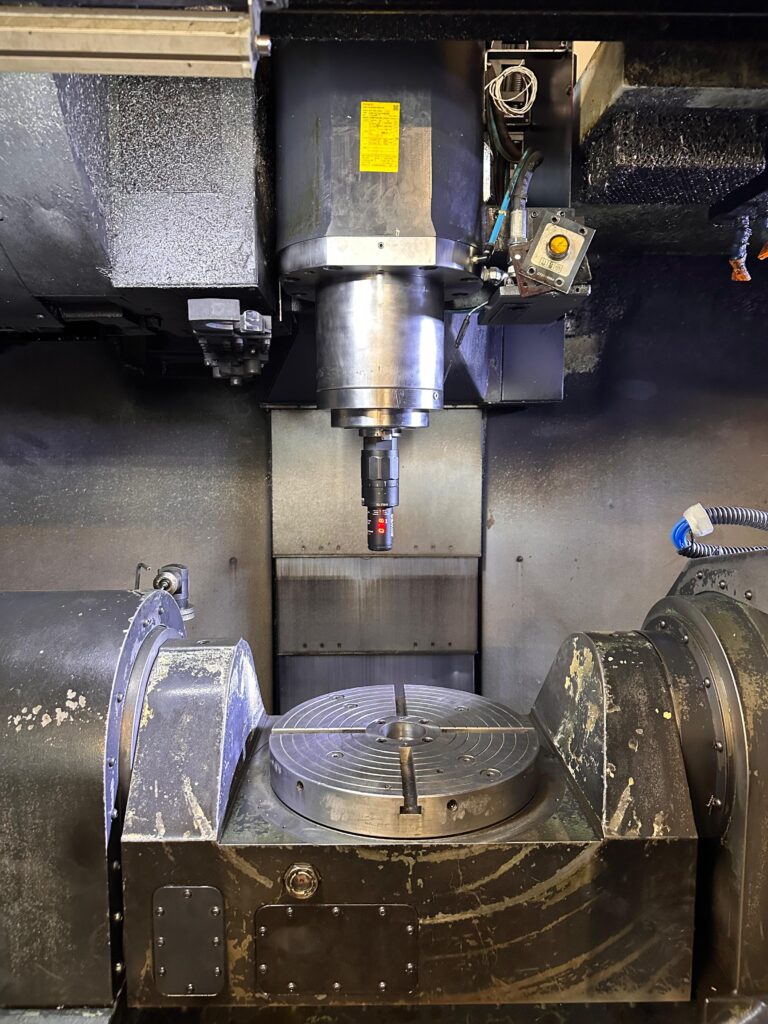

Spindle geometry setup

and axes in the DOOSAN DNM 350/5AX machine

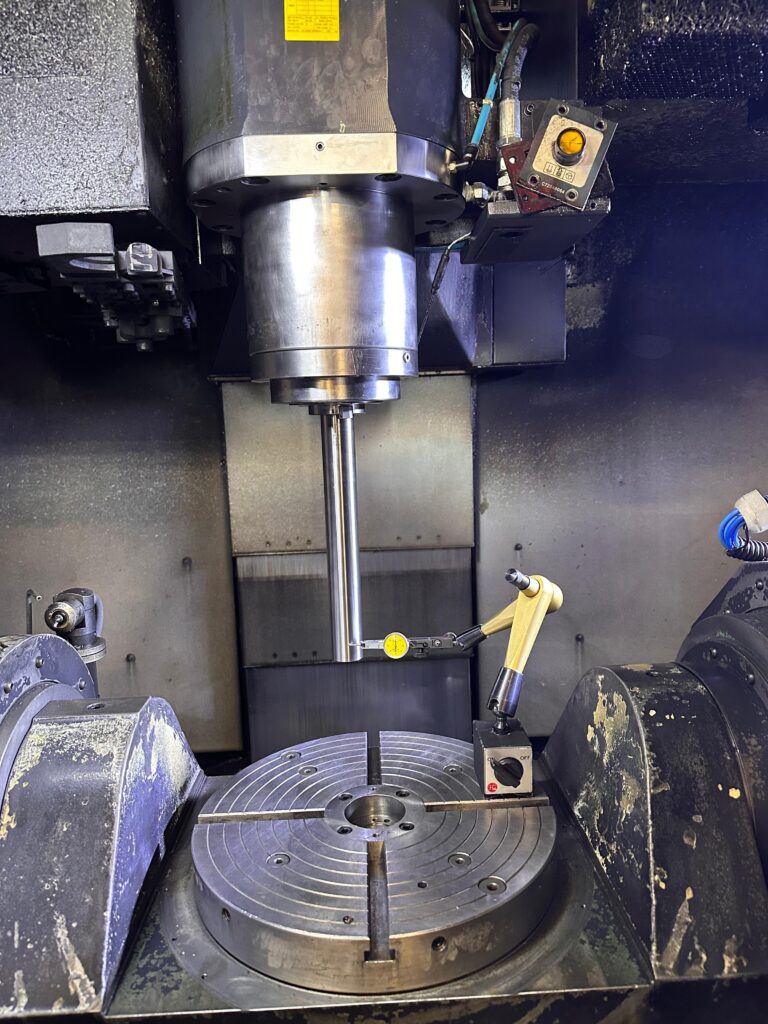

Repair alone is not enough. After the spindle returned to the plant, the customer’s maintenance department performed geometry setup of the spindle and all machine axes. After installation they verified squareness and parallelism, set angles, corrected errors and applied necessary compensations. In a 5-axis machine this is crucial: only after such setup can you speak about a full return to accurate, repeatable work. After this procedure the machine again holds tolerances in the micron range — precisely HALF A MICRON — and machining is stable even on demanding toolpaths.

Final result

DOOSAN DNM 350/5AX spindle repair

- bearing noise disappeared,

- radial runout dropped to reference values — exactly half a micron (0.0005 mm),

- the BT40 taper provides secure and repeatable tool clamping,

- 5-axis machining is stable at 15 000 rpm,

- downtime was reduced thanks to fast pickup and good cooperation with maintenance.

We have provided a 12-month service warranty on the repaired spindle. This confirms the work is durable and ready for real production, not just dry tests.

Summary

DOOSAN DNM 350/5AX spindle service

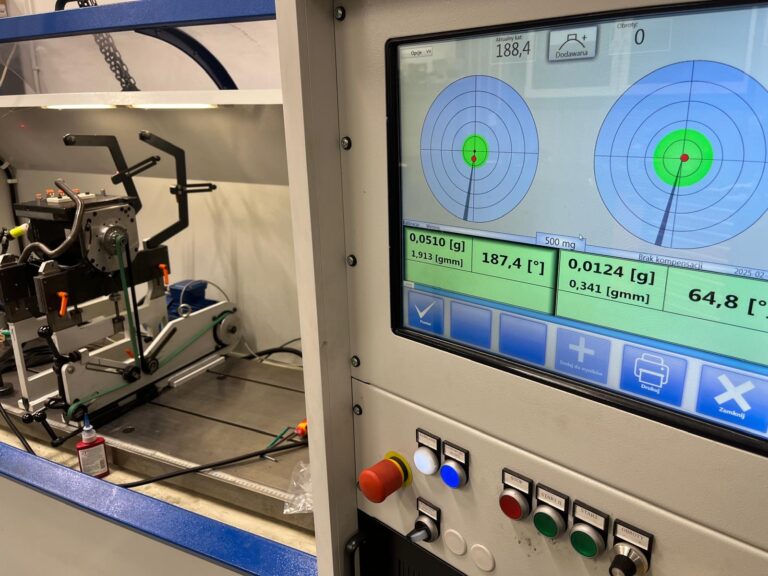

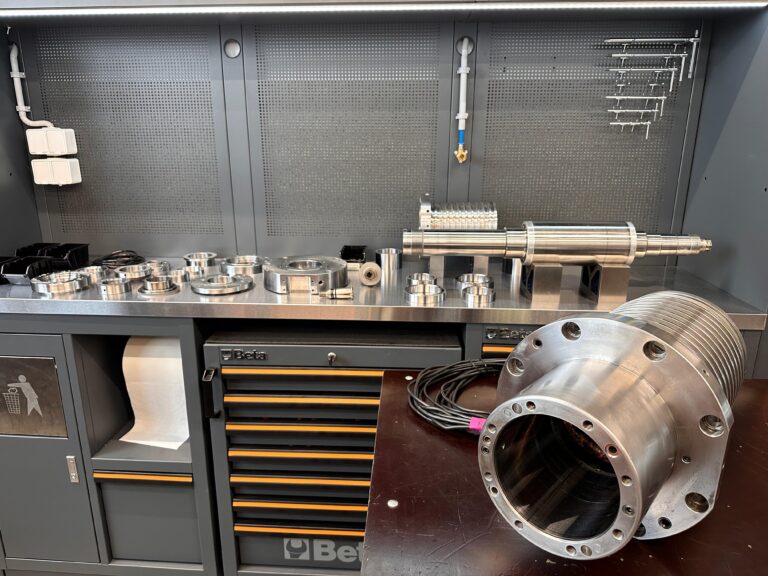

The DOOSAN/FANUC spindle in the DNM 350/5AX suffered a collision that caused loud bearing noise and high runout. We performed a complete repair: replacement of precision bearings, taper restoration, cleaning of all elements, assembly and balancing, followed by tests. On the customer side, the maintenance department set the geometry of the spindle and all axes, which completed the process. The machine returned to form and production is once again reliable and repeatable.