FANUM Machine Electrospindle Repair – HSD ES350L

FANUM Machine Electrospindle Repair – HSD ES350L (36,000 rpm, HSK E40)

-

Spindle manufacturer: HSD

-

Machine: FANUM

-

Speed: 36,000 rpm

-

Taper HSK E40

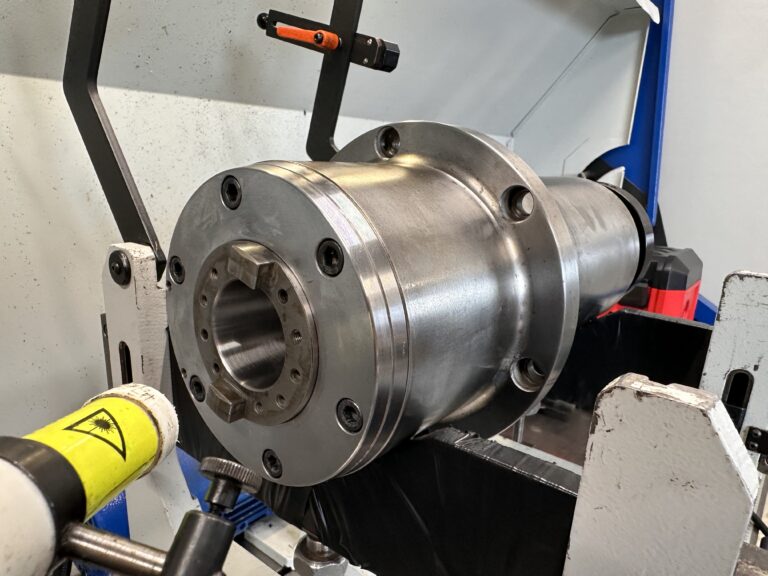

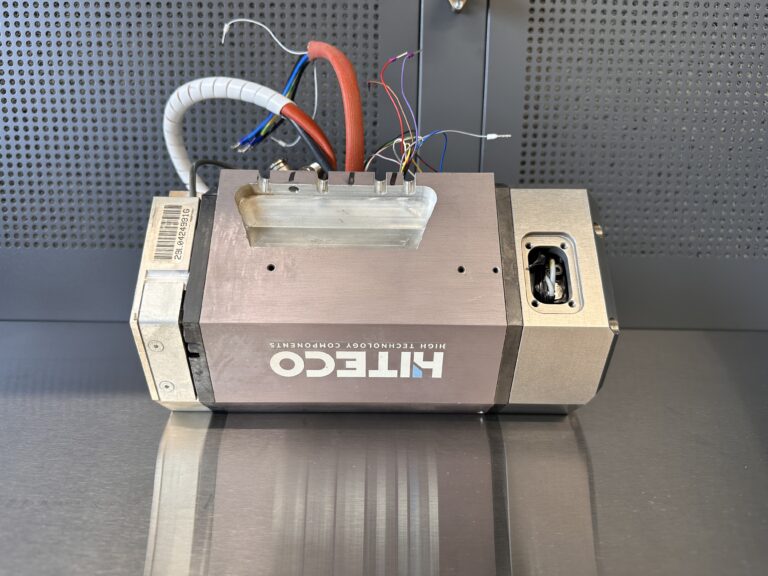

An HSD ES350L electrospindle from a FANUM machine arrived at our service center. The unit reported increased noise and noticeable vibrations at higher speeds. These are classic symptoms of high-speed bearing wear and a weakened tool drawbar. In such cases, a rapid, precise repair is crucial because every hour of machine downtime means real production costs.

Diagnostics

and condition verification of the HSD ES350L spindle

We began with full diagnostics:

- runout measurement,

- inspection of the HSK E40 taper condition,

- clamping force test and vibration analysis across the full speed range up to 36,000 rpm.

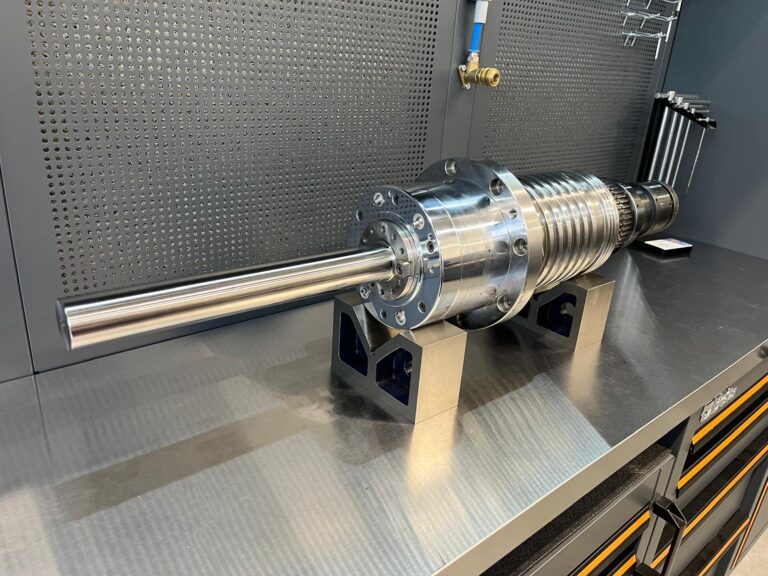

We confirmed the need to replace specialist high-speed bearings, as well as to overhaul the drawbar (Belleville springs, gripper segments, guides and seals). We also checked the bearing seats.

Scope of work – in bullet points

HSD ES350L electrospindle repair

BMS Spindle Service

Trusted HSD service for FANUM machines

If you’re looking for a proven partner for FANUM spindle overhauls or HSD electrospindle repairs — you’re in the right place.

BMS Spindle Service is a team that has been a leader in HSD electrospindle repairs in Poland and across Europe for years. Every year we service hundreds of units — from models used for wood and composites, to spindles operating in demanding CNC centers. We work fast (express options available) while ensuring full repeatability and process safety.

What you get

when you choose us for HSD ES350L repair

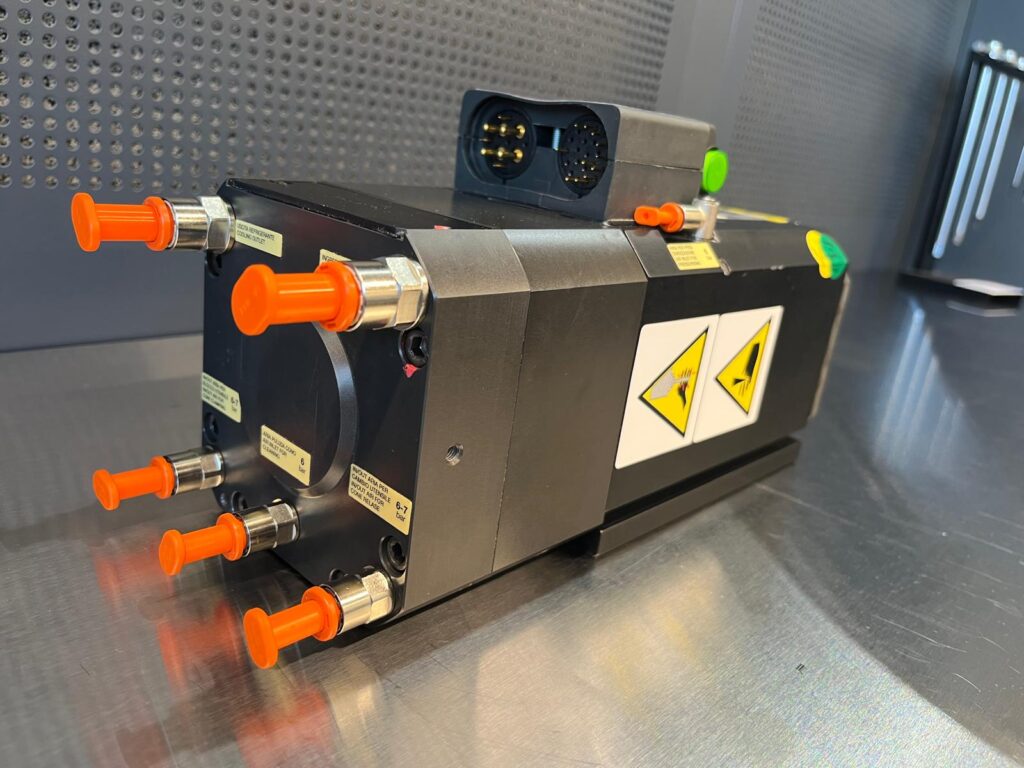

- Replacement of specialist high-speed bearings matched to 36,000 rpm

- Drawbar overhaul with clamping force measurement and calibration

- Precision balancing for high-speed operation

- Start-up and load tests across the full speed range

- Full service warranty and a clear measurement report

- Short lead times and support with spindle removal/installation in the FANUM machine

Frequently asked questions

about HSD ES350L electrospindle service

- Disassembly of the electrospindle and thorough cleaning.

- Replacement of specialist high-speed bearings matched to 36,000 rpm.

- Drawbar overhaul (refurbishment/replacement of parts + clamping force measurement and calibration).

- Precision dynamic balancing for high-speed operation (our practice: 0.4G).

- Start-up and load tests plus a measurement report.

Express HSD spindle repairs

are our everyday work

Need to restore your HSD ES350L electrospindle to full performance? Contact us — we’ll prepare a quote today, arrange safe transport and provide a fast, precise repair with warranty. Your FANUM machine will return to production quickly, giving you peace of mind and process stability.