SUNMIL milling machine spindle repair

Disassembly, repair and reassembly of ROYAL spindle

Spindle specifications:

- Spindle model: ROYAL

- Tool taper: SK40

- Rotational speed: 10 000 rpm

- Machine: SUNMIL milling machine

From disassembly to reassembly

Comprehensive repair of ROYAL spindle

The ROYAL spindle from a SUNMIL milling machine was delivered to our service. The order included full support – from spindle disassembly at the customer’s site, through complete repair, to final installation and machine start-up.

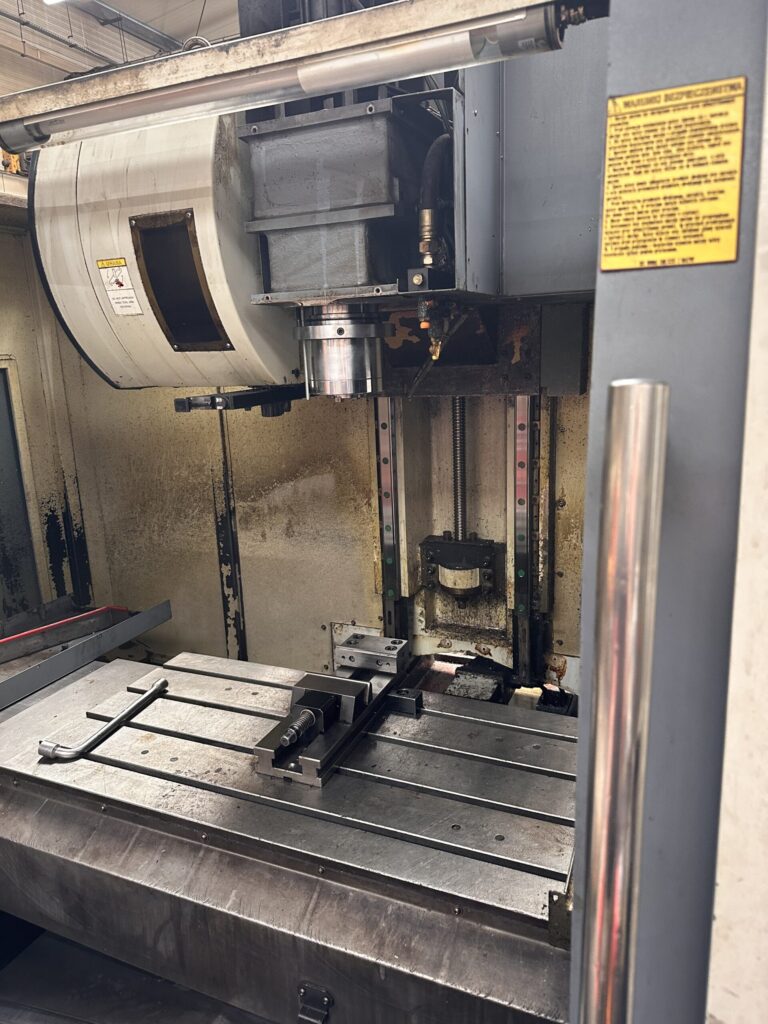

Spindle disassembly

at the customer's site

The first stage was a visit to the customer’s facility and the precise disassembly of the spindle from the SUNMIL milling machine. The operation went smoothly thanks to the experience of our mobile service team, which ensured proper protection of the component for transport.

Spindle repair process

ROYAL

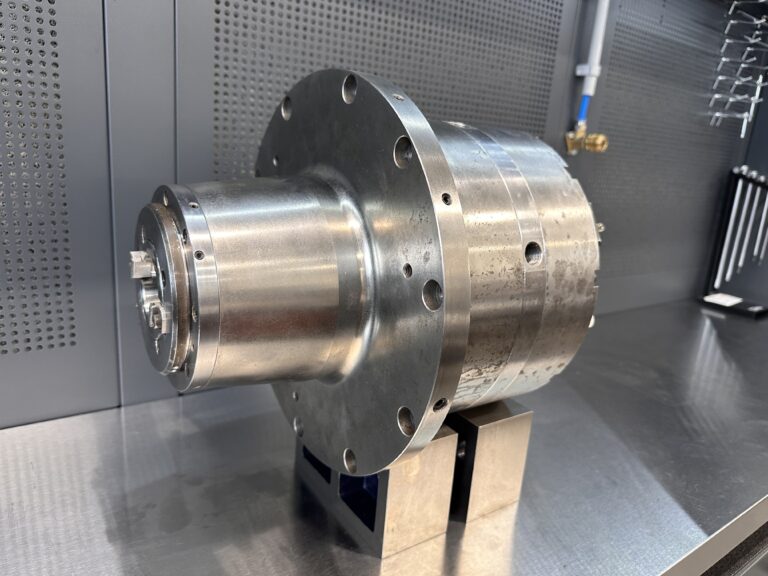

After the spindle was delivered to our service center, we began a multi-stage repair process:

1. Thorough initial diagnostics

Inspection of the spindle’s technical condition, clearance measurements, bearing wear analysis, and tool taper geometry check.

2. Spindle bearing replacement

The worn spindle bearings were removed and replaced with new, high-precision components adapted for 10,000 rpm operation.

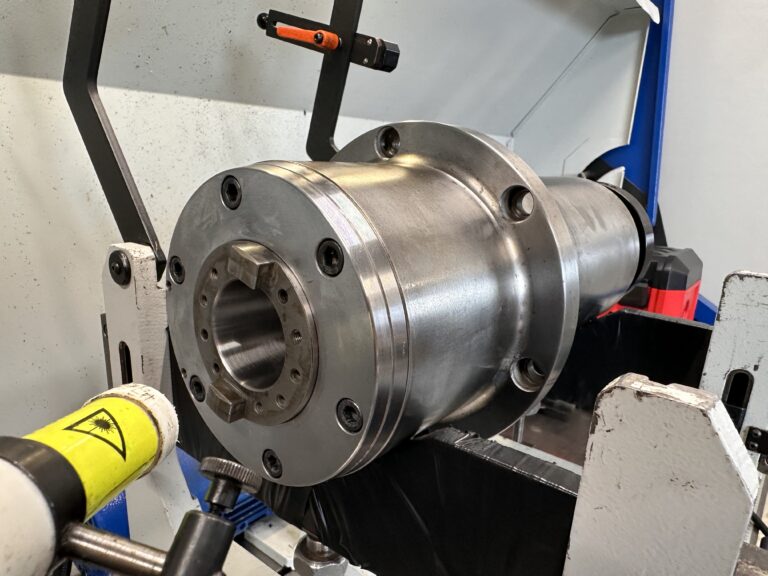

3. Precision dynamic balancing

Balancing was performed on a CIMAT machine, ensuring ideal balance and minimizing vibrations – a key factor for component longevity and machining quality.

4. SK40 taper repair

The tool holder taper was carefully ground and restored to its original geometric parameters.

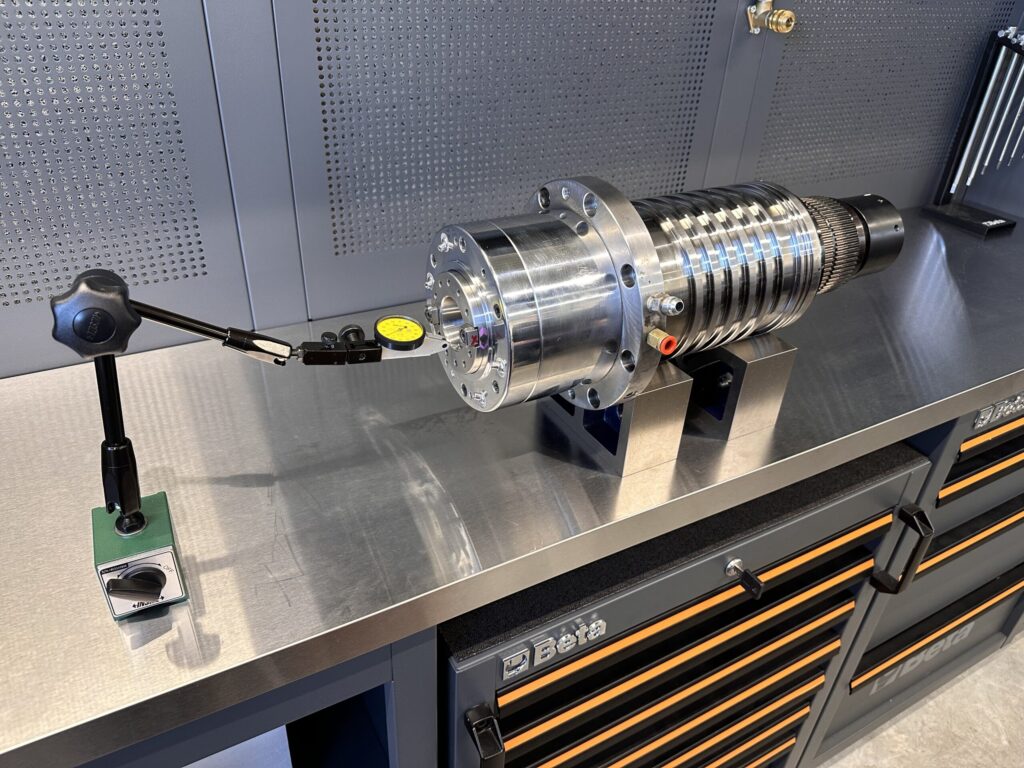

5. Rigorous performance tests

After reassembly, the spindle underwent:

- rotation tests at various speed ranges,

- tool clamping force measurement,

- radial and axial clearance checks,

- inspection of air and cooling system tightness.

6. Final measurements and report

All measurements were documented in a detailed final report confirming compliance with the manufacturer’s specifications.

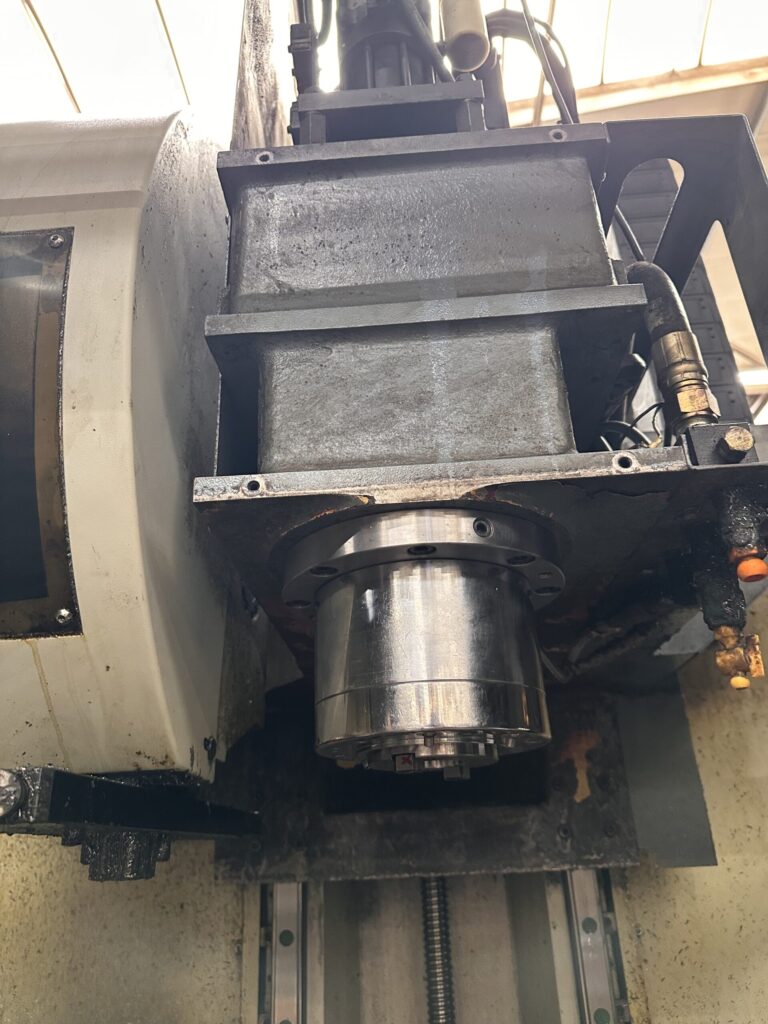

Installation

and commissioning at the customer’s site

After successful spindle repair, the ROYAL spindle was delivered to the customer and installed in the machine by our technicians. We performed startup and final on-site performance checks.

Warranty

and quality

The repaired ROYAL spindle is covered by a 6-month service warranty, confirming the quality of our work and the trust in the precision of our services.

Take care of your spindle – before it’s too late:

Need comprehensive spindle repair? Trust the experience of BMS SPINDLE SERVICE CNC – contact us today!