DMG MORI Spindle Repair – ISO40 Taper

DMG MORI spindle repair – ISO40

-

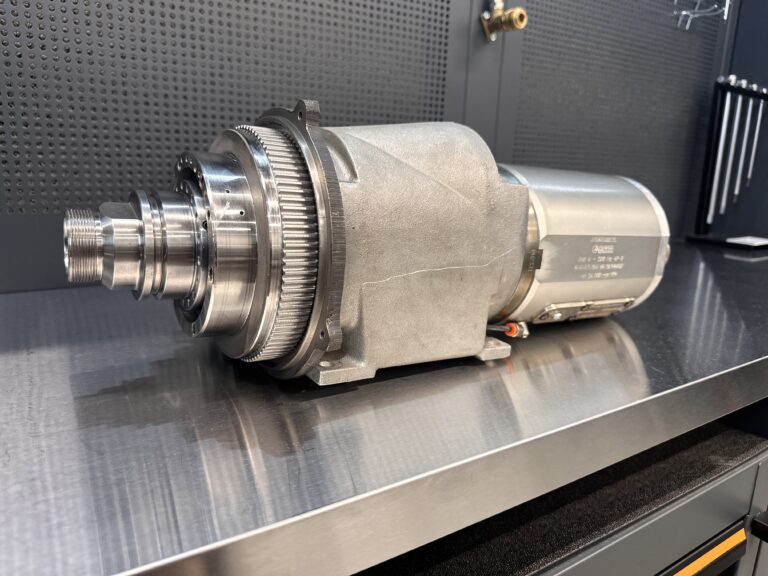

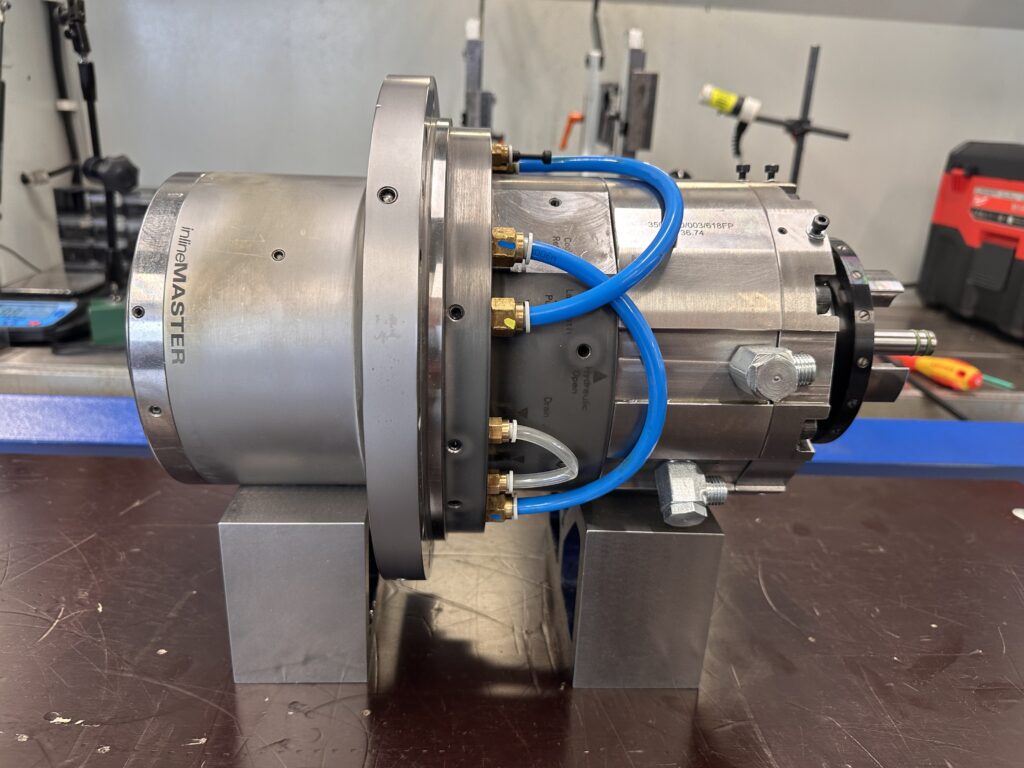

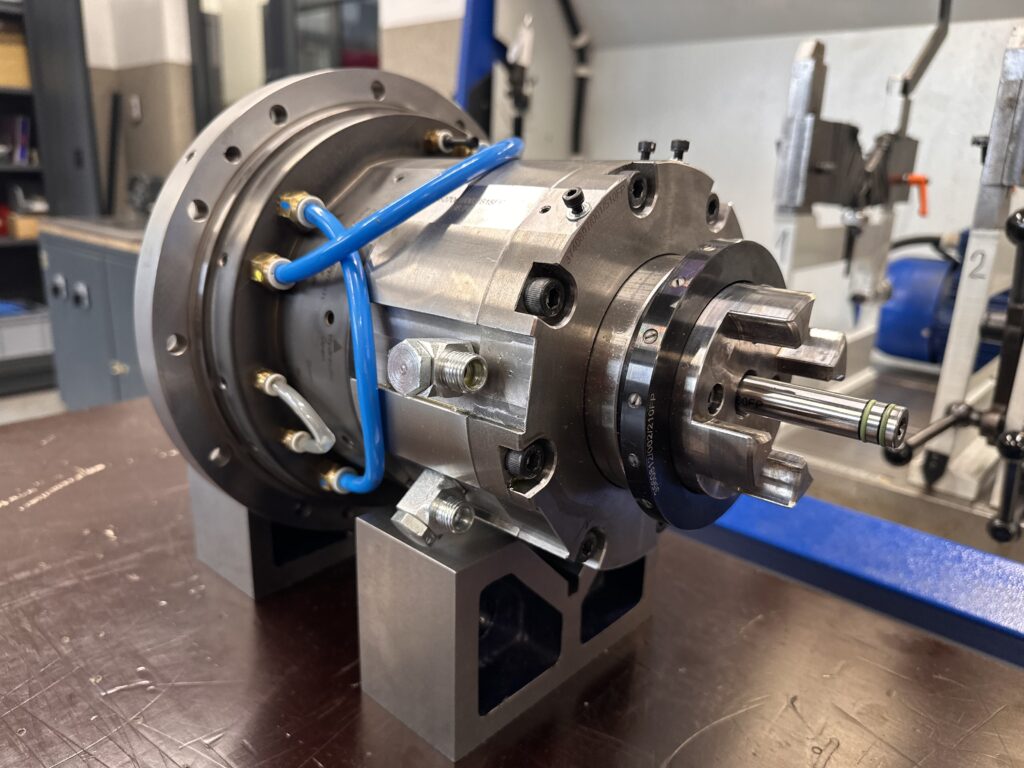

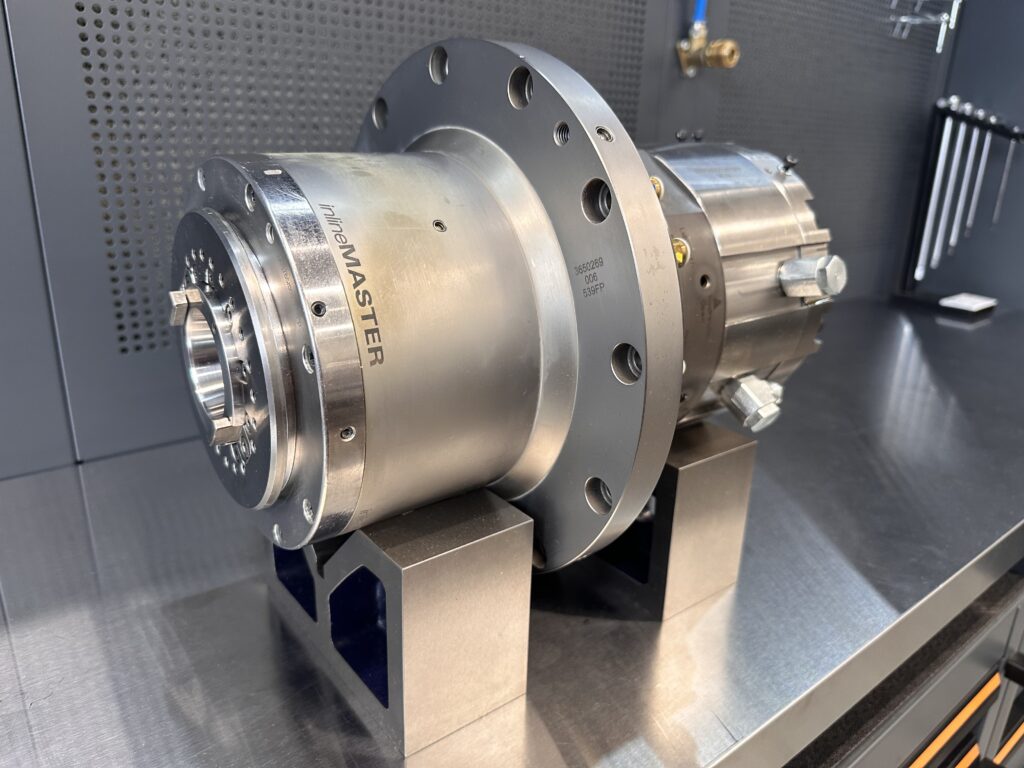

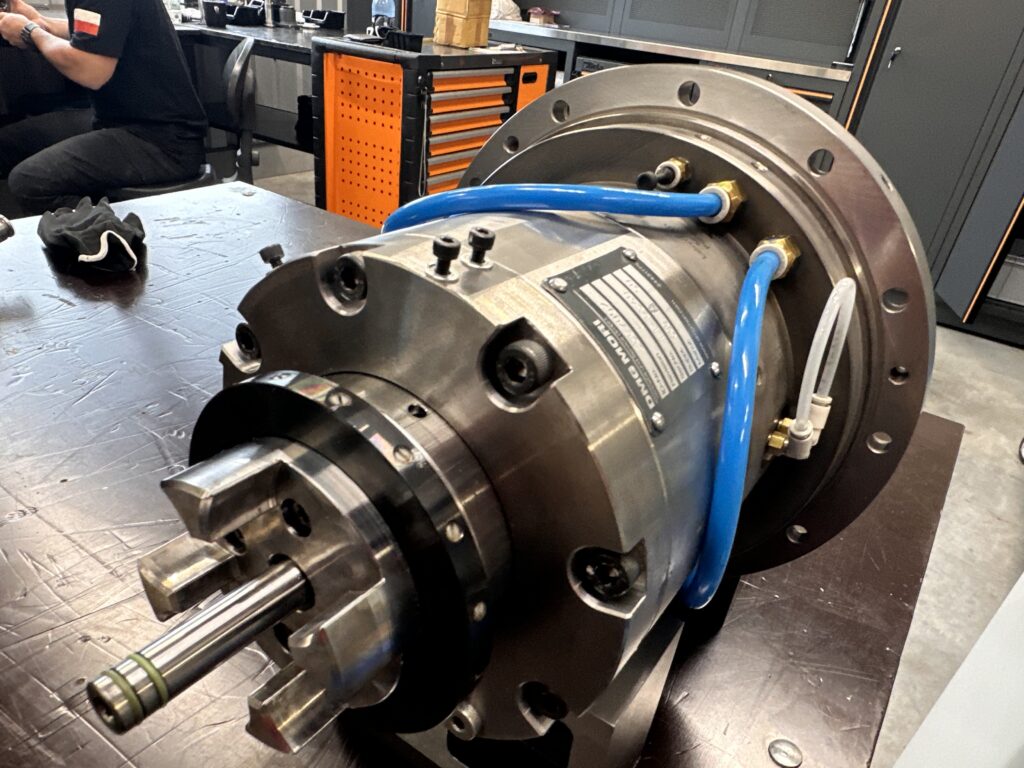

Spindle manufacturer: DMG MORI / inlineMASTER / KESSLER

-

Machine: DMG MORI

-

Spindle speed: 18 000 rpm

-

Taper: ISO40

A spindle from a machining center DMG MORI arrived at our service. It is a KESSLER inlineMASTER unit with an ISO40 taper and a maximum speed of 18 000 rpm. The customer reported increasing noise at higher speeds, noticeable vibration during milling and occasional problems with tool retention. After a short interview about the machine’s operation, we proceeded to full diagnostics.

Diagnostics

and condition check

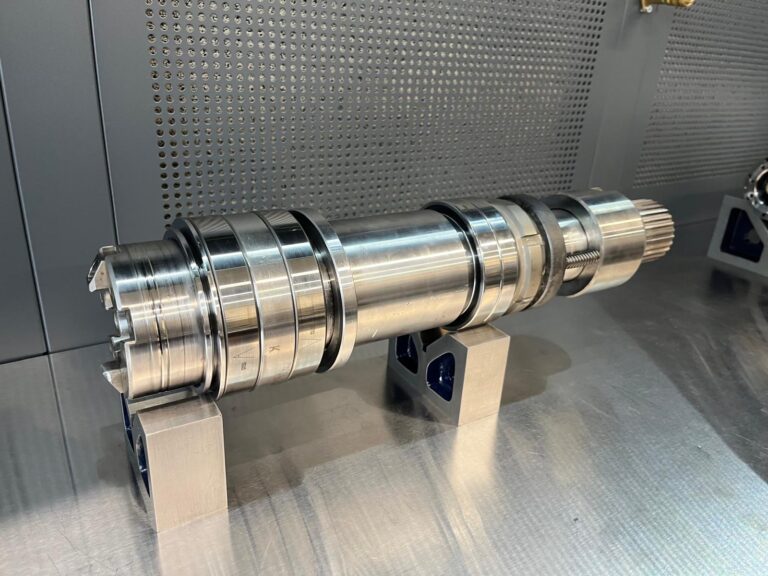

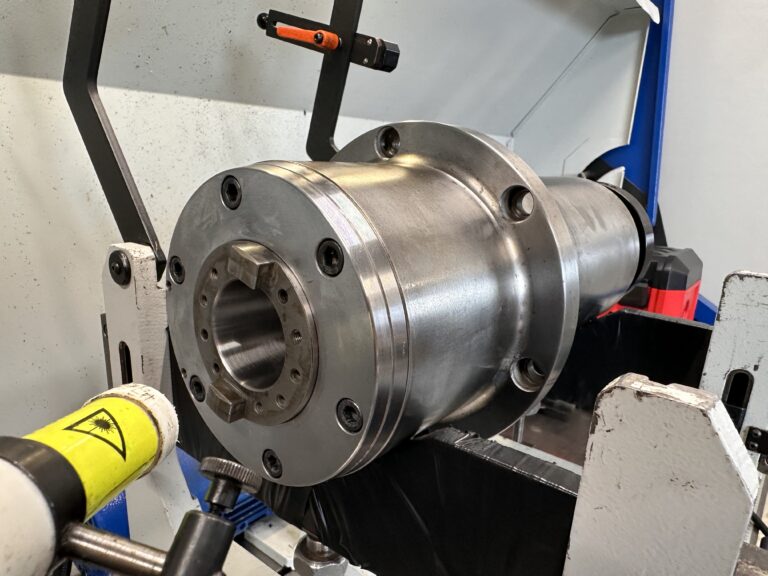

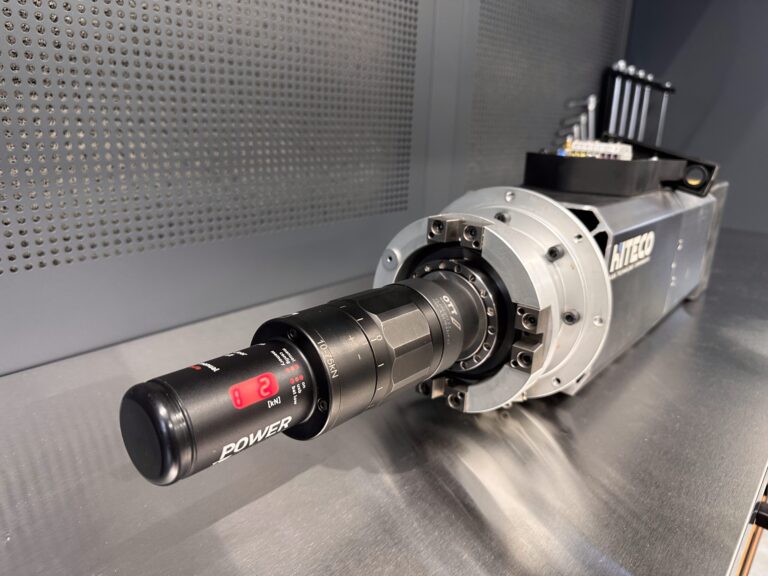

At the beginning we checked the condition of the ISO40 taper and the contact surface. There were visible wear marks and scratches, which usually appear after working with dirty toolholders or after an accidental bump during a tool change. Runout measurement confirmed it exceeded values acceptable for precise machining. Additional vibration and noise measurements indicated worn bearings, and the tool clamping force test showed unstable values. That was enough to decide on: bearing replacement, taper repair, balancing, drawbar service and sensor calibration.

Scope of work

DMG MORI spindle repair

Results after repair

DMG MORI spindle

After the entire process, the DMG MORI/KESSLER inlineMASTER spindle with ISO40 taper runs smoothly and quietly across the full speed range. Vibration dropped significantly, clamping force is stable, and surface finish improved already in the first customer trials. This means longer tool life, fewer downtimes and better process repeatability.

When to consider

a full service

If your DMG MORI shows similar symptoms — noise, vibration, marks on the ISO40 taper or a drop in clamping force — don’t postpone it. Bearing replacement, taper repair, balancing, drawbar repair and sensor calibration in one consistent process deliver the best results and visibly reduce production costs. We’ll be happy to handle the service from A to Z.

Similar symptoms?

Contact us

Do you need a comprehensive DMG MORI spindle service with ISO40 — from removal, through taper restoration, precise balancing, to drawbar repair and calibration? Write or call.